Flow battery positive electrode electrolyte based on tetrathiafulvalene dicarboxylic acid ethyl ester and preparation method of flow battery positive electrode electrolyte

A technology of ethyl tetrathiofulvalene dicarboxylate and ethyl fulvalene dicarboxylate, which can be used in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as inability to use water and narrow electrochemical window. , to achieve the effect of high redox potential, simple preparation and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

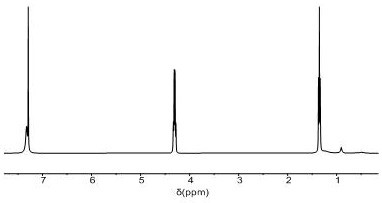

[0032] The preparation of embodiment 1 tetrathiofulvalene dicarboxylate methyl ester

[0033] Add 10mL (0.165mol) of carbon disulfide and 8.4g (0.1mol) of methyl propiolate as raw materials to 80mL of anhydrous tetrahydrofuran, then add 20.2g (0.1mol) of catalyst tributylphosphine, under the protection of argon, at -76 ℃ temperature reaction for 4 hours, after suction filtration, air drying at 80 ℃ for 6 hours, the crude product was chromatographed with a mixed solvent of cyclohexane and dichloromethane with a volume ratio of 2:1 to obtain tetrathiofulvalene dicarboxylate Acid methyl ester 2.1g.

Embodiment 2 4

[0034] The preparation of embodiment 2 ethyl tetrathiofulvalene dicarboxylates

[0035] Add 0.32g (0.001mol) methyl tetrathiofulvalenedicarboxylate to 40mL of absolute ethanol, then add 0.2mL of concentrated sulfuric acid, react at 90°C for 4 hours under the protection of argon, add 400mL of deionized water The precipitate was precipitated, collected by filtration, and purified by column chromatography with a mixed solvent of cyclohexane and dichloromethane at a volume ratio of 3:1 to obtain 0.313 g of ethyl tetrathiofulvalene dicarboxylate.

Embodiment 3~6

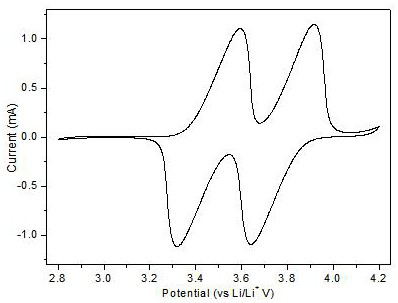

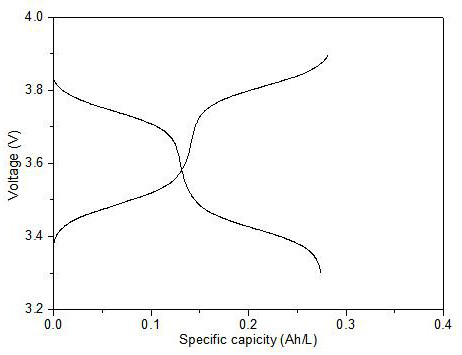

[0036] Examples 3-6 Preparation of positive electrode electrolyte for flow battery based on ethyl tetrathiofulvalene dicarboxylate

[0037] Two solvents, ethylene carbonate and dimethyl carbonate, were configured into 10mL mixed solutions according to different volume ratios, and then 1.52g of LiPF was added to the mixed solution 6 , and then add a certain quality of ethyl tetrathiofulvalene dicarboxylate, shake slightly until dissolved, and place it for use. The specific feeding formula of each embodiment is as shown in Table 1.

[0038] Table 1 The formula of the positive electrode electrolyte of flow battery based on tetrathiofulvalene dicarboxylate ethyl

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com