Segmented rail for high-pressure common rail system and control method of segmented rail

A high-pressure common rail system and segmented technology, applied in electrical control, charging system, engine control, etc., can solve problems such as poor stability and consistency, and achieve increased fuel injection rate, improved stability, and improved consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

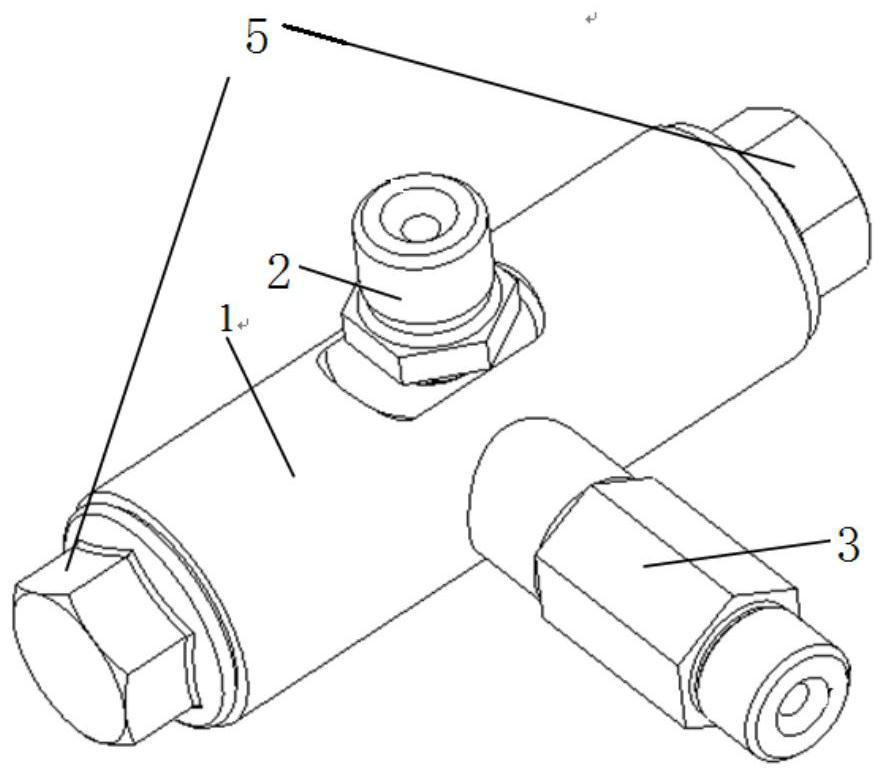

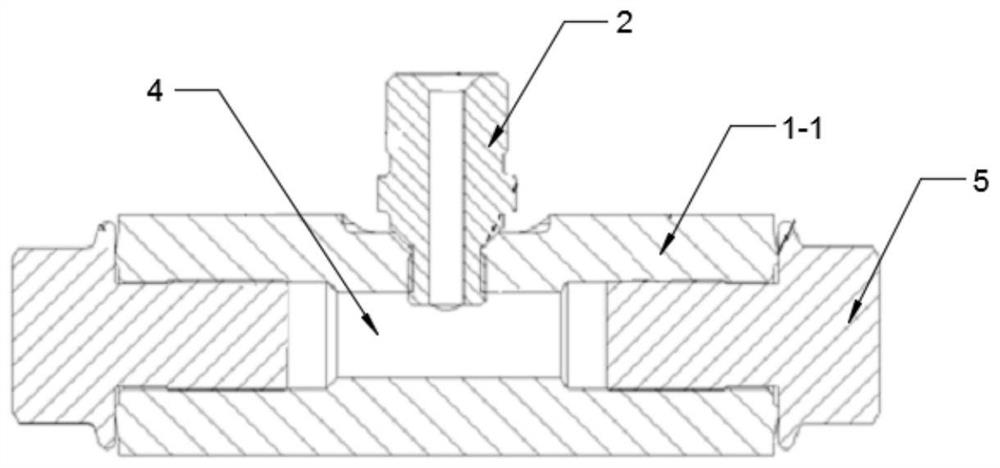

[0033] A segmented rail for a high-pressure common rail system, such as figure 1 with figure 2 As shown, it includes a segmented rail body 1 and a high-pressure conversion interface 2 and a check valve 3 that are sealed and installed on the segmented rail body 1;

[0034] The segmented rail body 1 is hollow to form an accumulator volume chamber 4 for containing high-pressure fuel, and the volume of the accumulator volume chamber 4 is greater than or equal to 40 times the maximum fuel injection volume per cycle of the electronically controlled injector;

[0035] The one-way valve 3 communicates with the accumulator volume chamber 4, and high-pressure fuel enters the accumulator volume chamber 4 in one direction through the one-way valve 3; The high-pressure fuel in the accumulator volume chamber 4 flows out through the high-pressure conversion interface 2 and enters the electronically controlled fuel injector.

[0036] Since the volume of the accumulator volume chamber 4 is ...

Embodiment 2

[0038] This embodiment introduces its detailed structure on the basis of Embodiment 1.

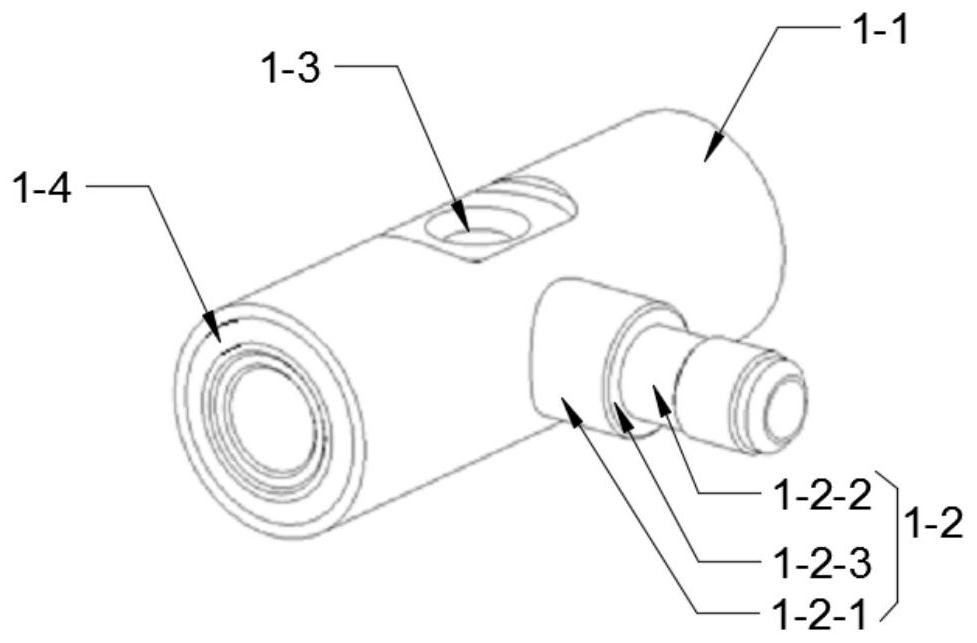

[0039] Specifically, as image 3 As shown, the segmented rail body 1 is a "T"-shaped structure, including an integrally connected rail body body 1-1 and a one-way valve connecting body 1-2 for installing the one-way valve 3; The pressure-volume cavity 4 is located in the rail body 1-1, and the rail body 1-1 is provided with an installation port 1-3 for installing the high-voltage conversion interface 2.

[0040] Specifically, as Figure 4 As shown, the installation port 1-3 includes a threaded area 1-3-1, a tapered surface 1-3-2, and a plane 1-3-3 from bottom to top, and the high-pressure conversion interface 2 and the threaded area 1 - 3-1 threaded connection, and press against the tapered surface 1-3-2 to form a seal, and the flat surface 1-3-3 is to facilitate tight installation with the high-pressure conversion interface 2.

[0041] As a preference, both ends of the rail body 1-1 ar...

Embodiment 3

[0049] This embodiment introduces its control method based on Embodiment 2.

[0050] The above-mentioned high-pressure common rail system uses the segmented rail control method. When the fuel pressure outside the check valve 3 is greater than the fuel pressure in the accumulator volume chamber 4, the check valve 3 is opened, and the high-pressure fuel passes through the check valve. 3 One-way entry into the accumulator volume chamber 4 for high-pressure fuel replenishment;

[0051] When the fuel pressure outside the check valve 3 is less than or equal to the fuel pressure in the accumulator volume chamber 4, the check valve 3 is closed without affecting the fuel pressure of adjacent electronically controlled injectors.

[0052] Specifically, the fuel pressure outside the one-way valve 3 refers to the pressure F of the high-pressure fuel at the inlet 3-1-1 of the one-way valve cap 3-1 acting on the ball valve 3-2. 1 .

[0053] The fuel pressure in the accumulator volume chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com