Preparation method of HMX/ANPyO eutectic crystal under two-dimensional material confinement doping condition

A technology of two-dimensional materials and conditions, applied in offensive equipment, explosives processing equipment, nitrated acyclic/alicyclic/heterocyclic amine explosive composition, etc., can solve the problem of inability to ensure the crystal eutectic state and the molar ratio of the constituent molecules The same problems, to achieve the effect of easy control of experimental conditions, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

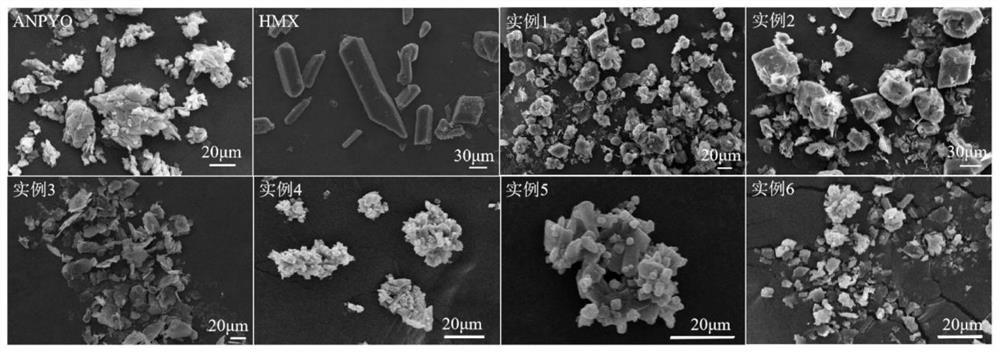

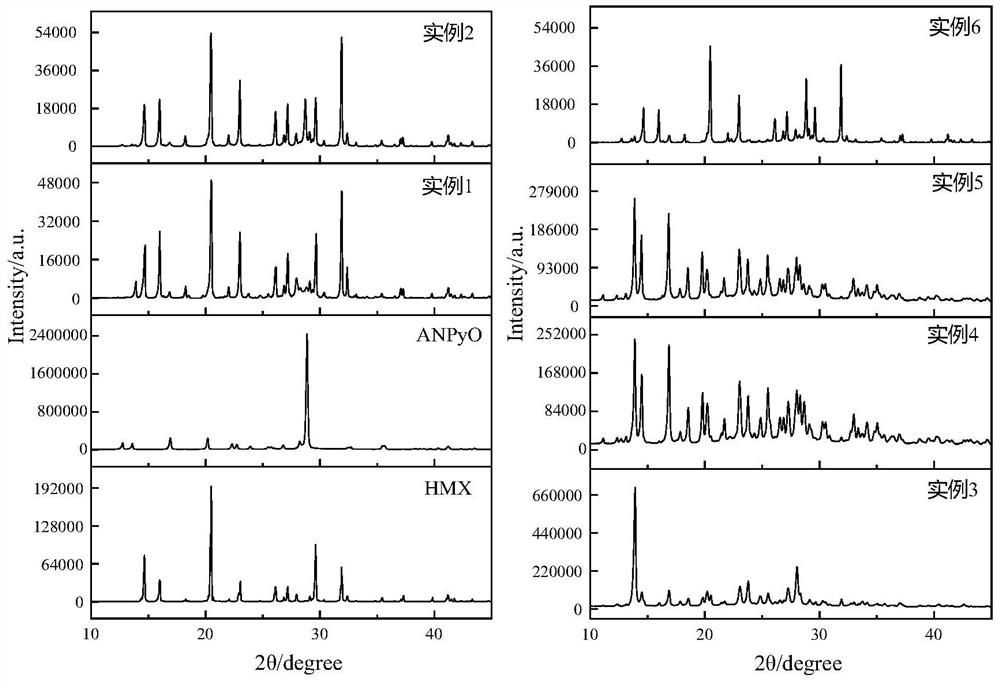

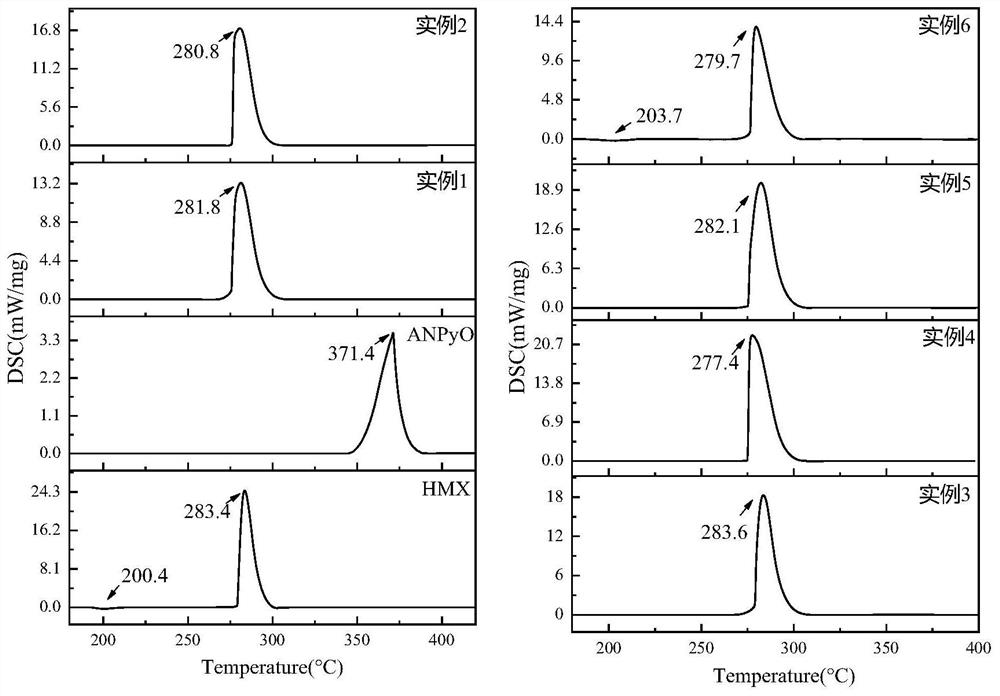

Examples

example 1

[0028] A preparation method of HMX / ANPyO eutectic under the confinement doping condition of a two-dimensional material, comprising the following process steps:

[0029] Dissolution of triaminoguanidine nitrate: Weigh 0.235g of triaminoguanidine nitrate and add it to 7.01ml dimethyl sulfoxide, heat to 140°C in a water bath (oil bath, electric heating), and magnetically stir (rotor speed 1000r / min) 10min to completely dissolve triaminoguanidine nitrate.

[0030] Dissolution of ammonium nitrate explosive: Weigh 1 g of Octogold, 0.168 g of ANPyO (the molar ratio of Octogold to ANPyO is 4:1, the total molar ratio of triaminoguanidine nitrate to the two explosives is 1:3) and add Into the dissolved triaminoguanidine nitrate solution, use a magnetic stirrer to stir for a period of time until Octogen and ANPyO are completely dissolved, and the solution turns reddish orange (the time in this example is 1h).

[0031] Formation of high-nitrogen two-dimensional conjugated structure mater...

example 2

[0039] A preparation method of HMX / ANPyO eutectic under the confinement doping condition of a two-dimensional material, comprising the following process steps:

[0040] Dissolution of triaminoguanidine nitrate: Weigh 0.564g of triaminoguanidine nitrate and add it to 16.18ml dimethyl sulfoxide, heat to 140°C in a water bath (oil bath, electric heating), and magnetically stir (rotor speed 1000r / min) 10min to completely dissolve triaminoguanidine nitrate.

[0041] Dissolution of ammonium nitrate explosive: Weigh 2g of Octogold, ANPyO0.6723g (the molar ratio of Octogold to ANPyO is 2:1, the total molar ratio of triaminoguanidine nitrate to the two explosives is 1:3) and add Into the dissolved triaminoguanidine nitrate solution, use a magnetic stirrer to stir for a period of time until Octogen and ANPyO are completely dissolved, and the solution turns reddish orange (the time in this example is 1h).

[0042] Formation of high-nitrogen two-dimensional conjugated structure material:...

example 3

[0050] A preparation method of HMX / ANPyO eutectic under the confinement doping condition of a two-dimensional material, comprising the following process steps:

[0051] Dissolution of triaminoguanidine nitrate: Weigh 0.212g triaminoguanidine nitrate and add it to 6.48ml dimethyl sulfoxide, heat to 140°C in a water bath (oil bath, electric heating), and magnetically stir (rotor speed 1000r / min) 10min to completely dissolve triaminoguanidine nitrate.

[0052] Dissolution of ammonium nitrate explosive: Weigh 1g of Octogold, ANPyO0.0840g (the molar ratio of Octogold to ANPyO is 8:1, the total molar ratio of triaminoguanidine nitrate to the two explosives is 1:3) and add Into the dissolved triaminoguanidine nitrate solution, use a magnetic stirrer to stir for a period of time until Octogen and ANPyO are completely dissolved, and the solution turns reddish orange (the time in this example is 1h).

[0053] Formation of high-nitrogen two-dimensional conjugated structure material: add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com