Method for preparing foam metal with controllable pore structure

A technology of foam metal and pore structure, applied in manufacturing, additive processing, etc., can solve the problems of incomplete dissolution of pore-forming agent, corrosion of matrix, etc., and achieve the effects of easy removal of residues, easy demoulding, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

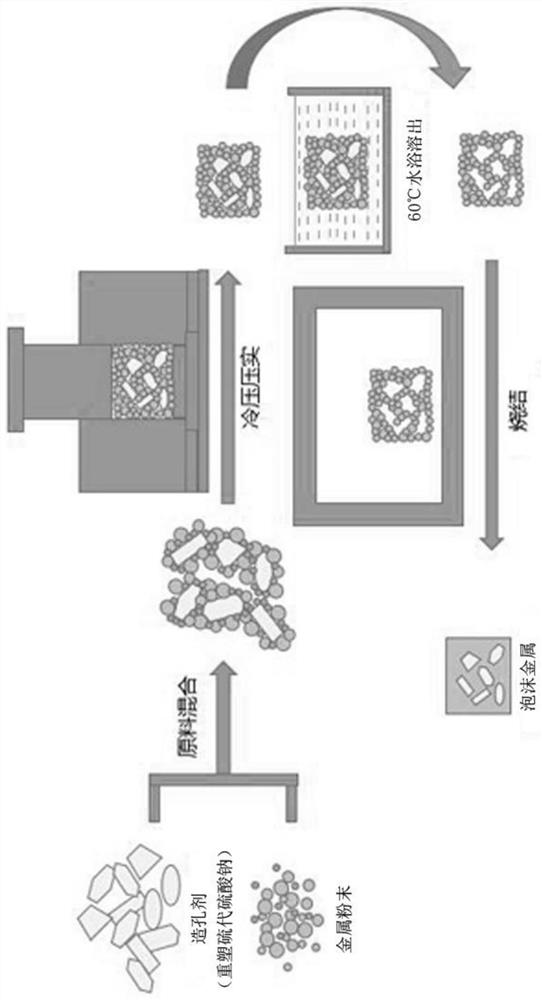

[0049] Such as figure 1 Shown is a method for preparing metal foam with controllable pore structure, using sodium thiosulfate as a pore-forming agent to prepare metal foam with controllable pore structure, comprising the following steps:

[0050] S1, metal foam pore structure design, determine the shape and structure of the hole: in this embodiment one, the shape of the metal foam hole is designed as a short rod, according to the porosity 65% and the shape of the hole of the metal foam to be formed, select Sodium thiosulfate is used as the raw material of pore-forming agent, and it is determined that pore-forming agent weight is 35.6g, and the material of metal powder is aluminum, and the weight of metal powder is 40.8g;

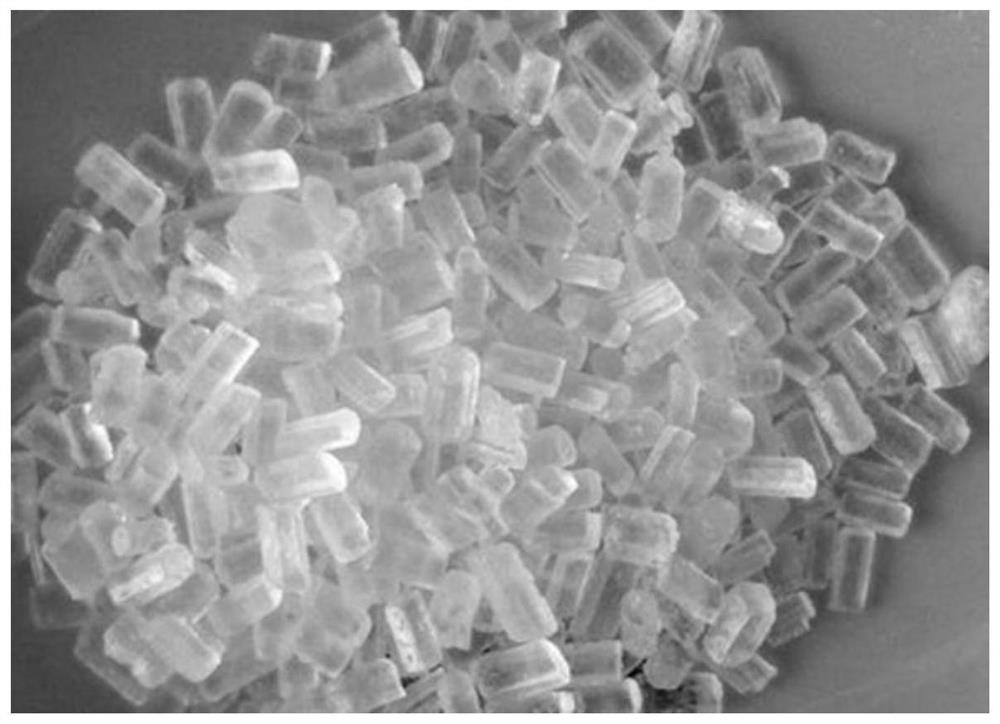

[0051] S2, according to the weight of the pore-forming agent determined in step S1, take the sodium thiosulfate particles, by figure 2 It can be seen that the initial state of the sodium thiosulfate raw material is a short rod, so directly take the short...

Embodiment 2

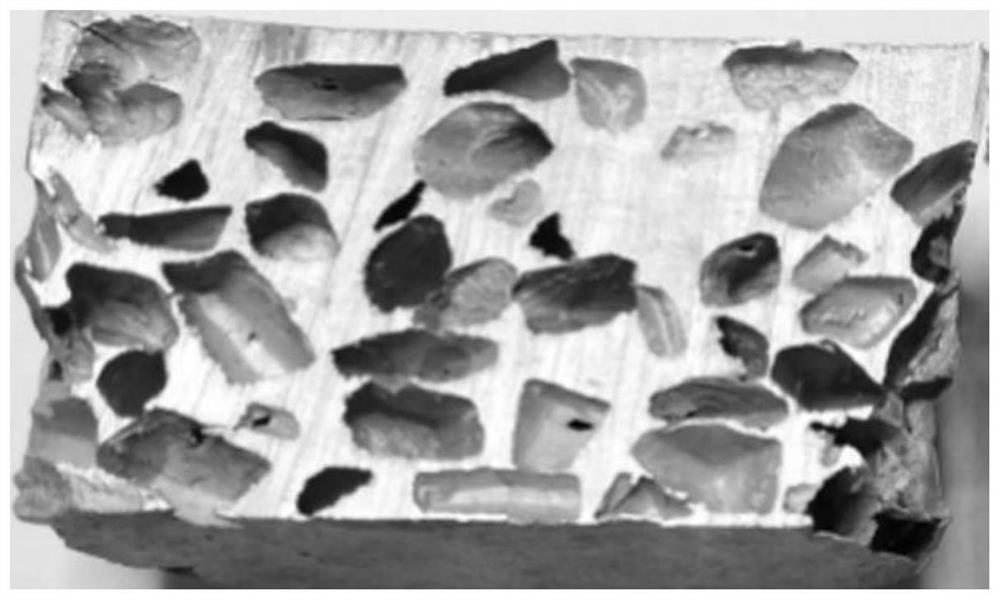

[0058] Such as figure 1 Shown is a method for preparing metal foam with controllable pore structure, using sodium thiosulfate as a pore-forming agent to prepare metal foam with controllable pore structure, comprising the following steps:

[0059] S1, metal foam pore structure design, determine the shape and structure of the hole: in this embodiment two, the shape of the metal foam hole is designed to be granular, according to the porosity 65% and the shape of the hole of the metal foam to be formed, select Sodium thiosulfate is used as the raw material of pore-forming agent, and it is determined that pore-forming agent weight is 35.6g, and the material of metal powder is aluminum, and the weight of metal powder is 40.8g;

[0060] S2, weigh the sodium thiosulfate particles according to the weight of the pore-forming agent determined in step S1, put the short rod-shaped sodium thiosulfate particles into a pulverizer and grind them into powder to obtain a particulate pore-formi...

Embodiment 3

[0067] Such as figure 1 Shown is a method for preparing metal foam with controllable pore structure, using sodium thiosulfate as a pore-forming agent to prepare metal foam with controllable pore structure, comprising the following steps:

[0068] S1, metal foam pore structure design, determine the shape and structure of the hole: in this embodiment three, the shape of the metal foam hole is designed to be spherical, according to the porosity 70% and pore shape of the metal foam to be formed, select sulfur Sodium sulfate is used as the raw material of pore-forming agent, and it is determined that pore-forming agent weight is 44.0g, and the material of metal powder is aluminum, and the weight of metal powder is 30.5g;

[0069] S2. Preparation of pore-forming agent with controllable shape:

[0070] First, if Figure 16 As shown, making the overturning mold: According to the shape of the pore-forming agent designed in step S1, ABS is selected as the raw material for 3D printing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com