Three-layer composite high-barrier controllable fully biodegradable mulch film and preparation method thereof

A technology of degrading plastic film and high barrier, applied in the fields of botanical equipment and methods, chemical instruments and methods, layered products, etc., can solve the problems of difficult operation, complicated process, low practicability of energy saving and consumption reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

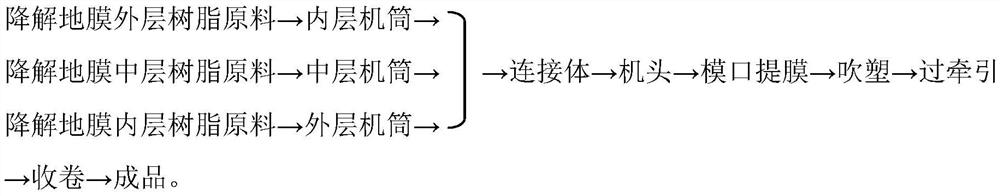

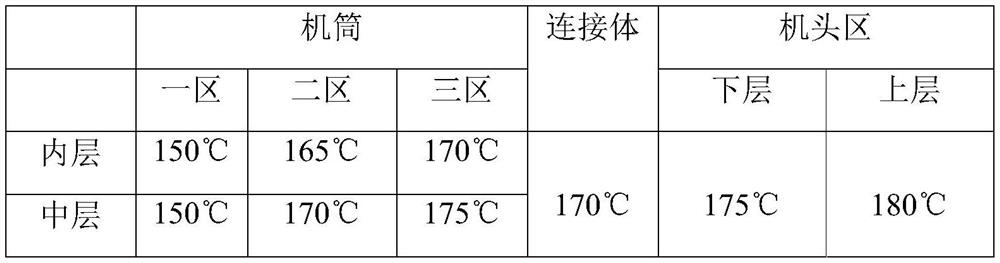

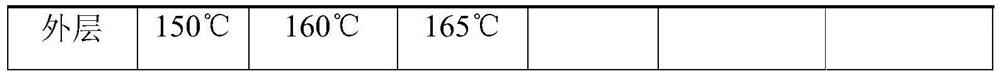

Method used

Image

Examples

Embodiment 1

Light stabilizer 0.125Kg; antioxidant 0.125Kg; lubricant 0.25Kg; dispersant 0.5Kg.

Middle layer: degradable mulch barrier resin is made of the raw material of following mass percentage:

[0088] PBAT: 87 wt.%; PLA: 6 wt.%; TPU: 4 wt.%; Lubricant: 1 wt.%; Dispersant: 2 wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 21.75Kg; PLA 1.5Kg; TPU 1Kg; lubricant

0.25Kg; dispersant 0.5Kg.

Inner layer: degradable plastic film slow-release layer resin is made of the raw material of following mass percentage:

[0091] PBAT: 80.5wt.%; PLA: 13wt.%; Lubricant: 1.5wt.%; Dispersant: 2wt.%; Coupling Agent:

3wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 20.125Kg; PLA 3.25Kg; lubricant 0.375Kg;

Dispersing agent 0.5Kg; coupling agent 0.75Kg.

Wherein:

PBAT is obtained by copolymerization of butylene adipate and butylene terephthalate, wherein butylene adipate and

The mass ratio of butylene terephthalate was 45:55. PB...

Embodiment 2

0.5Kg; light stabilizer 0.15Kg; antioxidant 0.2Kg; lubricant 0.25Kg; dispersant 0.5Kg.

Middle layer: degradable mulch barrier resin is made from the raw material of following mass percentage:

[0123] PBAT: 87 wt.%; PLA: 6 wt.%; TPU: 4 wt.%; Lubricant: 1 wt.%; Dispersant: 2 wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 21.75Kg; PLA 1.5Kg; TPU 1Kg; lubricant

0.25Kg; dispersant 0.5Kg.

Inner layer: degradable plastic film slow-release layer resin is made of the raw material of following mass percentage:

[0126] PBAT: 80.5 wt.%; PLA: 13 wt.%; Lubricant: 1.5 wt.%; Dispersant: 2 wt.%; Coupling agent:

3wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 20.125Kg; PLA 3.25Kg; lubricant 0.375Kg;

Dispersing agent 0.5Kg; coupling agent 0.75Kg.

wherein:

PBAT is obtained by copolymerization of butylene adipate and butylene terephthalate, wherein butylene adipate and

The mass ratio of butylene terephthalate was ...

Embodiment 3

Light stabilizer 0.2Kg; antioxidant 0.2Kg; lubricant 0.25Kg; dispersant 0.5Kg.

Middle layer: degradable mulch barrier resin is made from the raw material of following mass percentage:

[0146] PBAT: 87 wt.%; PLA: 6 wt.%; TPU: 4 wt.%; Lubricant: 1 wt.%; Dispersant: 2 wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 21.75Kg; PLA 1.5Kg; TPU 1Kg; lubricant

0.25Kg; dispersant 0.5Kg.

Inner layer: degradable mulch film slow-release layer resin is made of the raw material of following mass percentage:

[0149] PBAT: 80.5 wt.%; PLA: 13 wt.%; Lubricant: 1.5 wt.%; Dispersant: 2 wt.%; Coupling agent:

3wt.%.

25Kg per bag after above-mentioned raw material granulation, wherein: PBAT 20.125Kg; PLA 3.25Kg; lubricant 0.375Kg;

Dispersing agent 0.5Kg; coupling agent 0.75Kg.

wherein:

PBAT is obtained by the copolymerization of butylene adipate and butylene terephthalate, wherein butylene adipate and

The mass ratio of butylene terephthalate was 45:55....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com