Integrated circuit board surface dust-free heat dissipation and cooling assembly

A circuit board and integrated technology, which is applied in the field of dust-free heat dissipation and cooling components on the surface of integrated circuit boards, can solve problems such as waste of wind energy, affecting the service life of circuit boards, and lack of dust removal structures for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

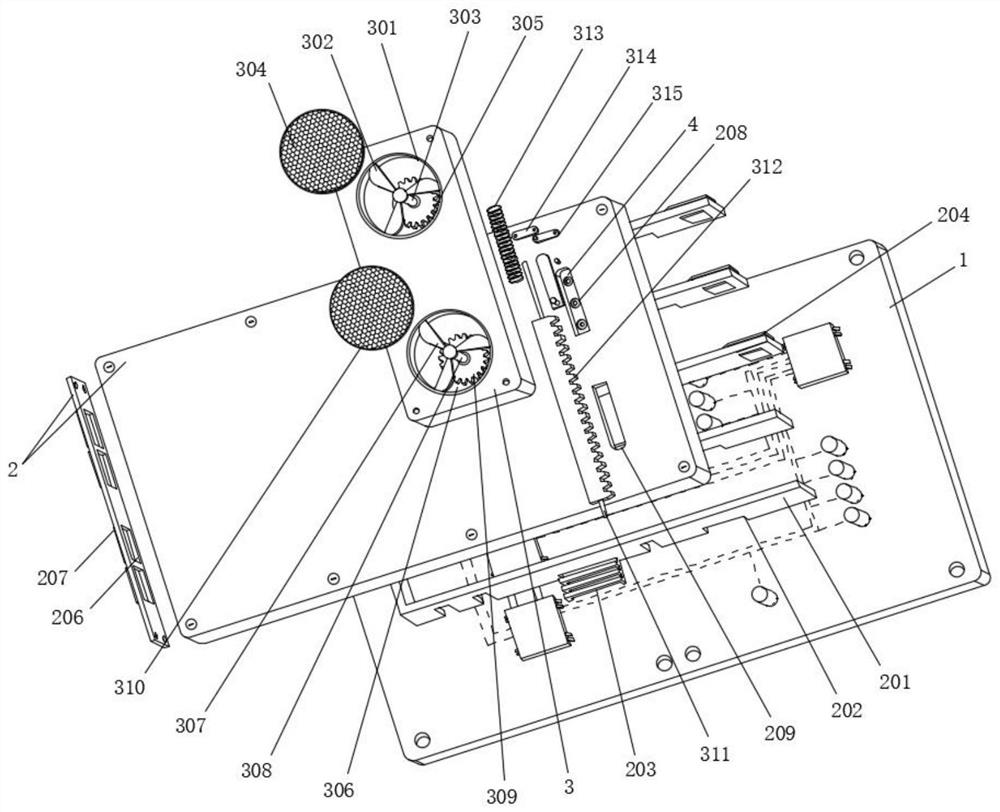

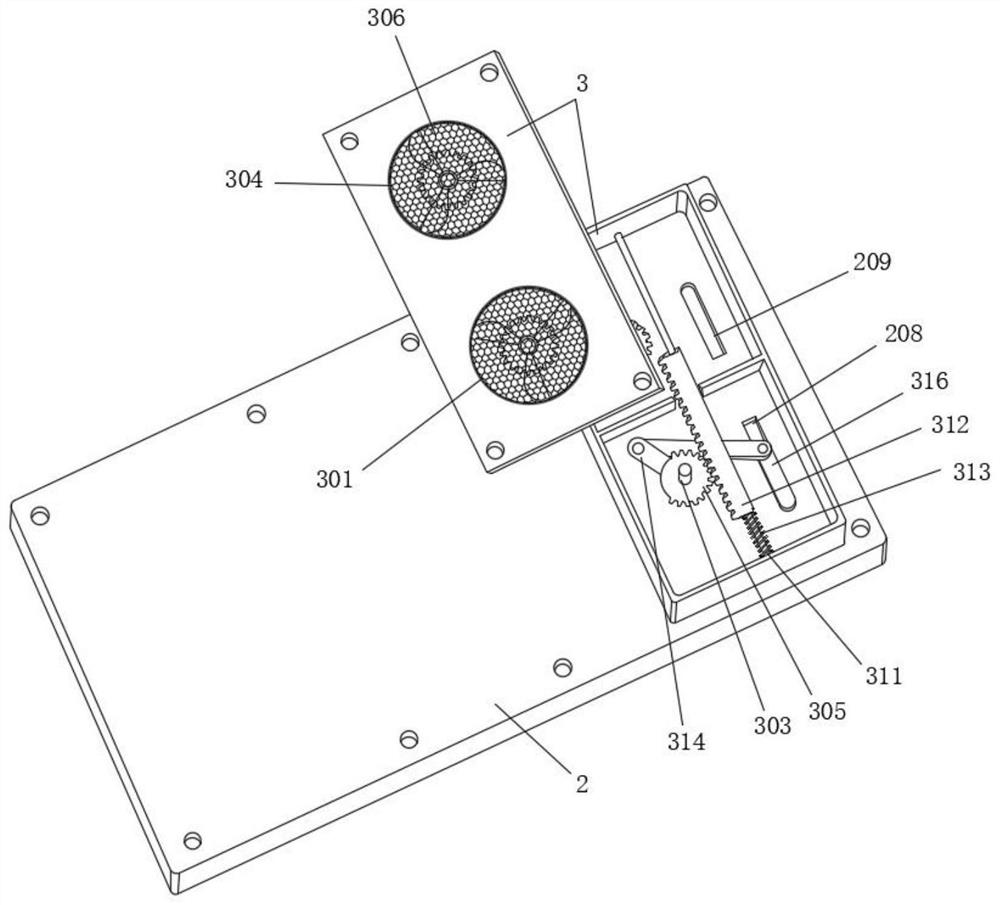

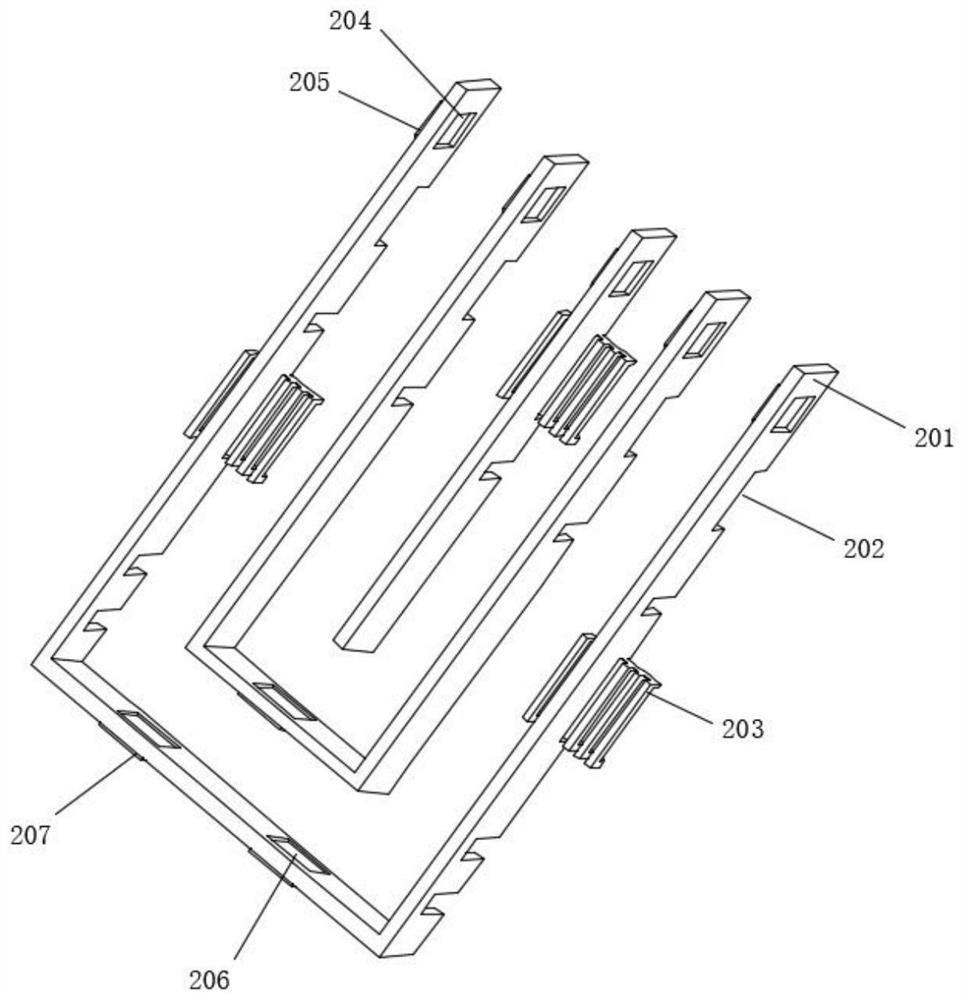

[0031] Such as Figure 1-Figure 8As shown, an integrated circuit board surface dust-free heat dissipation and cooling assembly according to the present invention includes a PCB board 1, a heat dissipation box 2, an air box 3 and a regulator 4, and a heat dissipation box 2 is fixed on the PCB board 1, and the heat dissipation box 2 is fixedly connected with the bellows 3 as an integral structure, the bellows 3 is also provided with a regulator 4, and a number of cooling plates 201 are fixedly connected in the cooling box 2, and the cooling plates 201 are provided with an adapter groove 202 and a cooling cover 203. The front end of 201 is provided with No. 1 pressure relief hole 204, No. 1 pressure relief hole 204 edge is fixedly connected with No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com