Alkylation reaction device and technique

A technology of alkylation reaction and alkylation reactor, which is applied in alkylation reaction unit, reactor for alkylation reaction of isoparaffin and olefin and in the field of alkylation reaction, which can solve the problem of affecting alkylate oil products. Quality, mass transfer and low reaction rate, side reactions of materials in the tube, etc., to achieve the effect of improving the reaction rate and product selectivity, improving the alkylation reaction rate, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

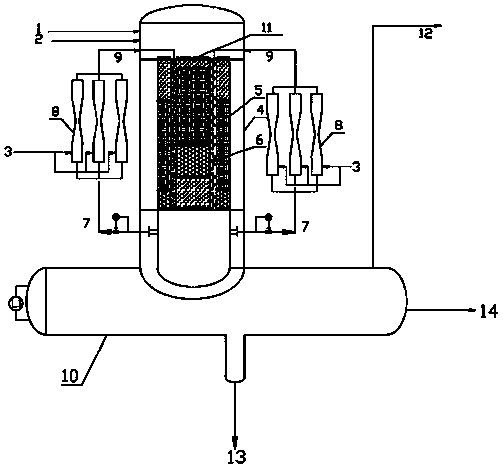

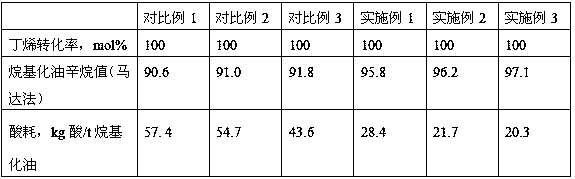

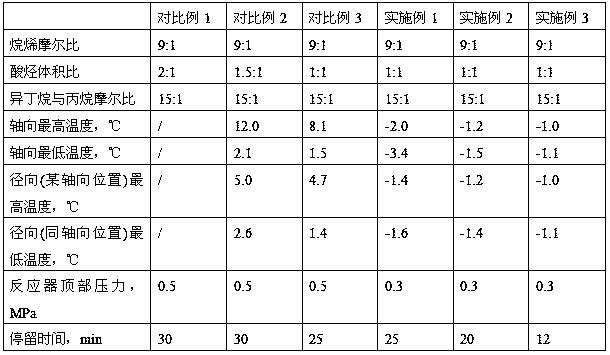

[0039] By adopting the method of the present invention, three groups of alkylation reaction sections and three-phase separators at the bottom are set, wherein the alkylation reaction section is composed of a packing tube bundle area and a refrigerant microbubble area, and the packing tube bundle is only made of the packing tube bundle of the present invention In the way of internal packing, the refrigerant microbubbles are dispersed in the tube bundle by atomized refrigerant microbubbles, and the atomized refrigerant from the gas-liquid refrigerant aspirator is dispersed into microbubbles, which act on the filler tube bundle. A three-phase separator is connected to the bottom of the reactor to separate vaporized refrigerant, crude alkylate and mixed sulfuric acid. The reaction conditions and results are shown in Table 1 and Table 2, respectively.

Embodiment 2

[0041] By adopting the method of the present invention, three groups of alkylation reaction sections and three-phase separators at the bottom are arranged, wherein the alkylation reaction section is composed of a packing tube bundle area, a refrigerant vaporization area and a refrigerant microbubble area, and the packing tube bundle The structure is composed of a material pre-mixing section and an internal packing section (height ratio 1:12). A refrigerant vaporization section, refrigerant vaporization pipeline and corresponding pressure control system are arranged at the lower part of each group of alkylation reaction sections. The micro-bubbles of the agent adopt the atomized refrigerant micro-bubble dispersion tube bundle, and the atomized refrigerant from the gas-liquid refrigerant aspirator is dispersed into micro-bubbles, which act on the filler tube bundle. A three-phase separator is connected to the bottom of the reactor to separate vaporized refrigerant, crude alkylate...

Embodiment 3

[0043] By adopting the method of the present invention, three groups of alkylation reaction sections and three-phase separators at the bottom are set, wherein the alkylation reaction section is composed of a packing tube bundle area, a refrigerant gasification area and a refrigerant microbubble area, and the packing tube bundle It is composed of a material pre-mixing section and an internal packing section (height ratio 1:8), and a refrigerant vaporization section, refrigerant vaporization pipeline and corresponding pressure control system are arranged at the lower part of each group of alkylation reaction sections; The bubble adopts atomized refrigerant micro-bubble dispersion tube bundle, and the atomized refrigerant from the gas-liquid refrigerant aspirator is dispersed into micro-bubbles, which act on the packing tube bundle. The bottom of the reactor is connected with a three-phase separator to separate vaporized refrigerant, crude alkylate and mixed sulfuric acid. The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com