Battery film tearing device and method

A film device and battery technology, applied in the directions of packaging, transportation and packaging, climate sustainability, etc., can solve the problems of unqualified insulation performance, lack of battery tear film, scratched shell, etc., to reduce difficulty, solve battery bumps, The effect of improving the efficiency of secondary rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0033] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

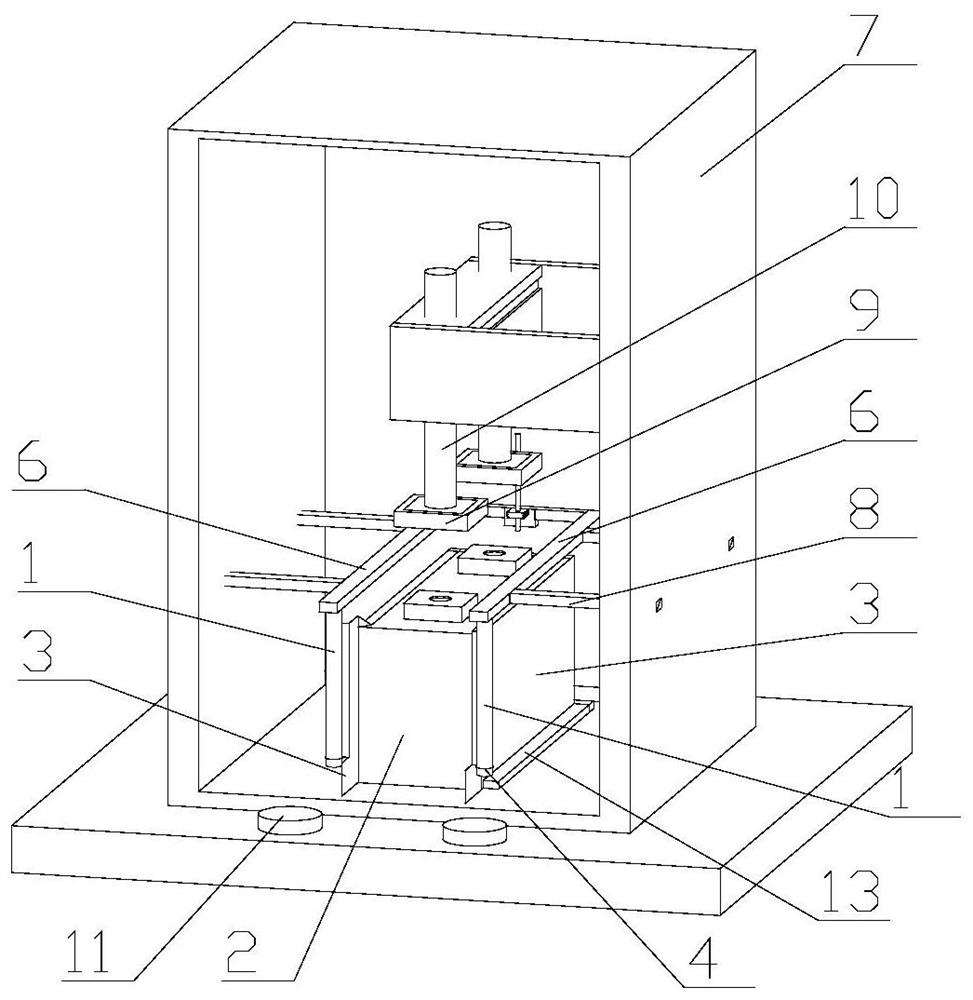

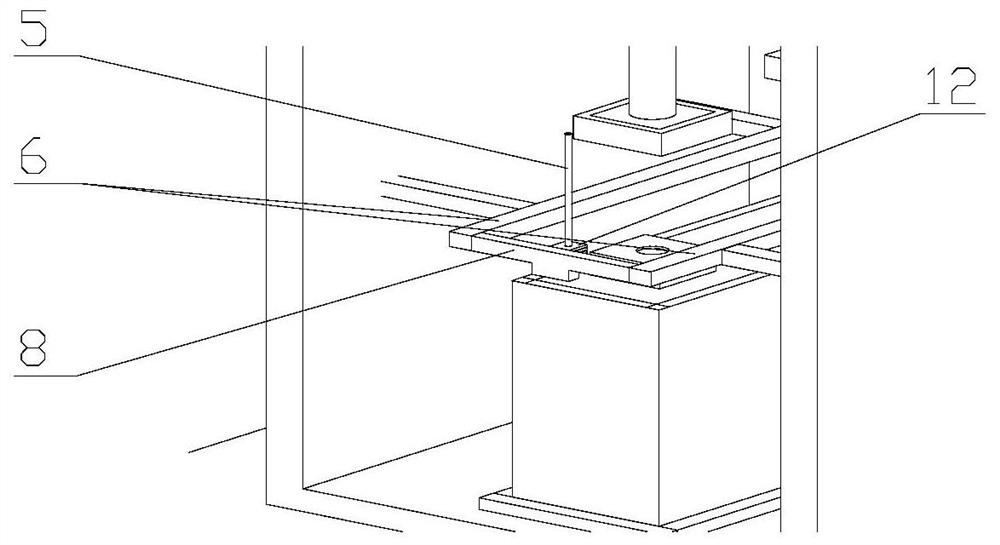

[0034] combine Figure 1-Figure 3 According to one aspect of the present invention, a battery tearing device is provided, the battery tearing device includes:

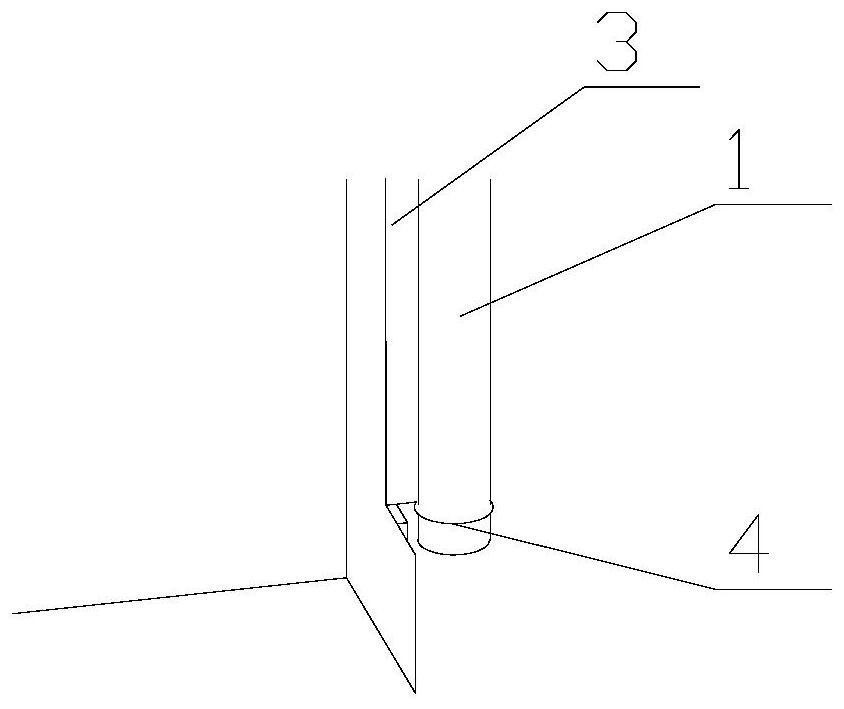

[0035] Two tear film units 1, the two tear film units 1 are arranged to be respectively fixed with the first tear end and the second tear end of the insulating film 3 torn from one end of the battery 2, so as to separate from the battery 2 respectively. tearing the insulating film 3 on the side of the battery 2 along the length direction of the battery 2 on both sides of the battery 2; and

[0036] A cutting unit 4, the cutting unit 4 is configured to be able to cut the insulating film 3 during the film tearing process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com