Numerical control machine tool with laser heating function

A CNC machine tool and laser heating technology, applied in metal processing, tool holder accessories, metal processing equipment, etc., can solve the problems of apparent indicators not passing, difficult to detect, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

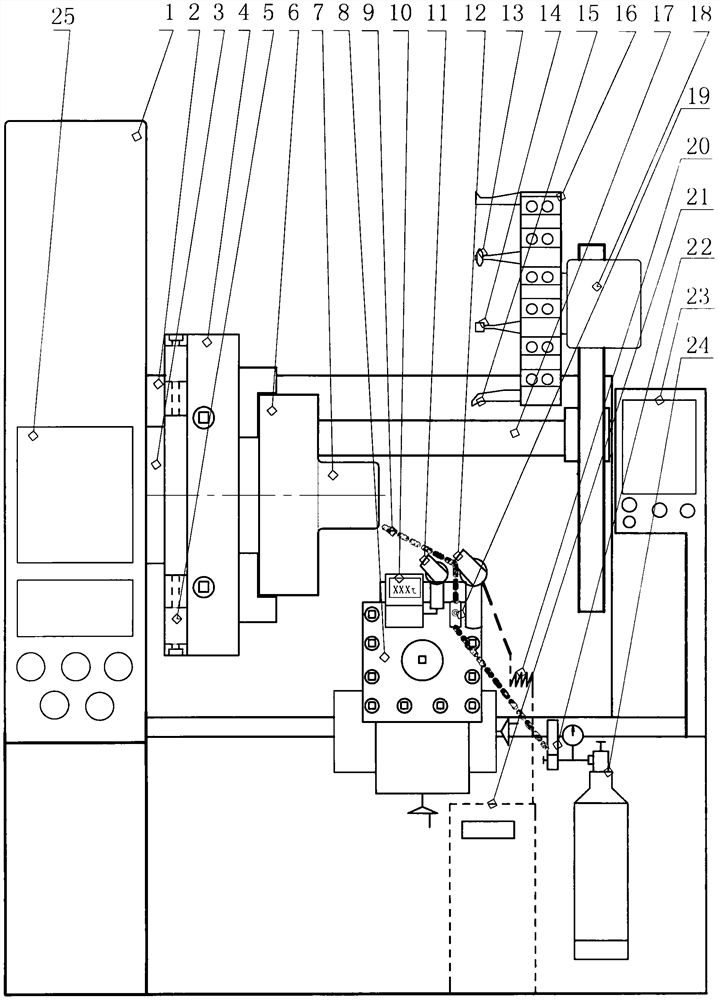

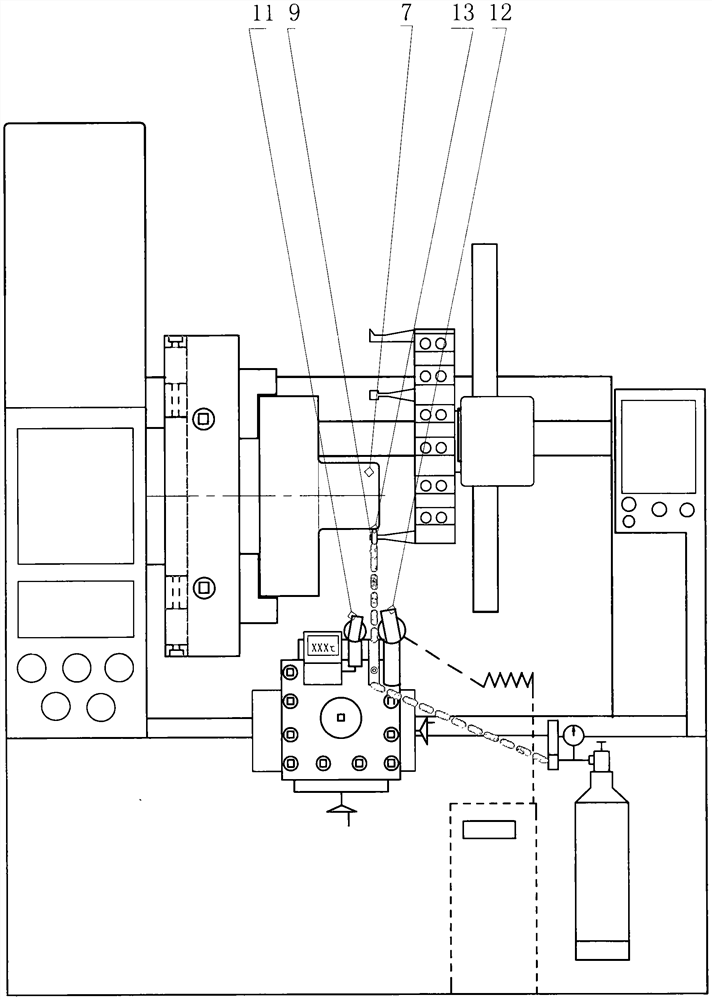

[0017] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

[0018] As shown in the figure, this application is a CNC machine tool with laser heating function, including a CNC machine tool mechanism, a carriage mechanism, a heating mechanism, and a protection mechanism;

[0019] Described numerical control machine tool mechanism comprises dynamic balance sense detector and dynamic balance detection instrument 25, rotating shaft 3, base plate 2, chuck 4, adjustable balance weight 5, track 17, numerical control sliding table 18, numerical control cutterhead 16, have Spinning head 13, polishing head 14 and cutting tool 15; Described sense of balance detector is arranged on the rear section of rotating shaft 3 of numerical control machine tool, and described balance detector instrument 25 is arranged on the control cabinet 23 of numerical control machine tool 1, and detects with sense of balance ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com