Method for improving performance uniformity of thermo-mechanically rolled steel plate and thermo-mechanically rolled steel plate

A technology of thermomechanical rolling and uniformity, which is applied in metal rolling and other directions, can solve the problems of poor performance uniformity of thermomechanical rolled steel plates, achieve excellent performance uniformity, and improve the effect of performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

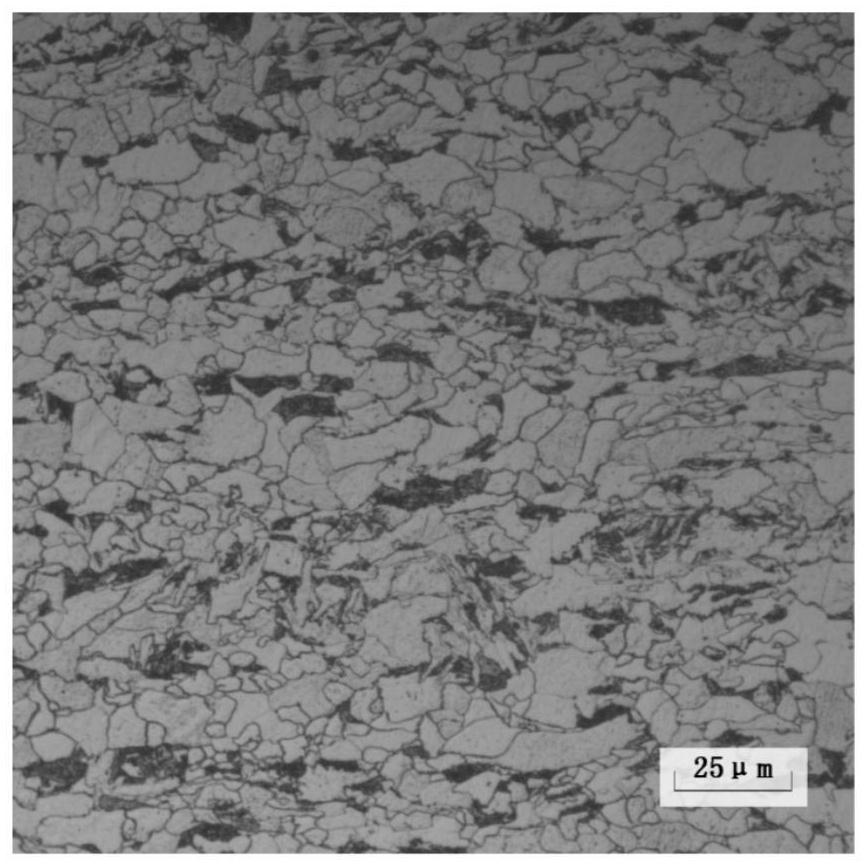

Image

Examples

Embodiment 1

[0050] The target thickness of the steel plate is 16mm, and the yield strength of the steel plate is 370MPa.

[0051] The chemical composition of the steel plate is designed according to mass percentage: C=0.10%, Si=0.25%, Mn=1.50%, P=0.010%, S=0.0015%, Cr=0.10%, Nb=0.03%, Ti=0.015%, The balance is Fe and other unavoidable impurities, and common precious elements such as Ni, Cu, V and Mo are not intentionally added.

[0052] The key process steps and parameters of steel plate thermomechanical rolling are as follows:

[0053] (1) Billet heating: the billet heating temperature is 1180°C, the continuous casting billet with a thickness of 200mm is selected, and the billet is in the furnace for 210 minutes:

[0054] (2) Controlled rolling: After the steel billet leaves the heating furnace, it enters the descaler for descaling, and then enters the rough rolling mill for rough rolling. Swing air cooling is carried out between passes; model rolling is used for finish rolling, and wh...

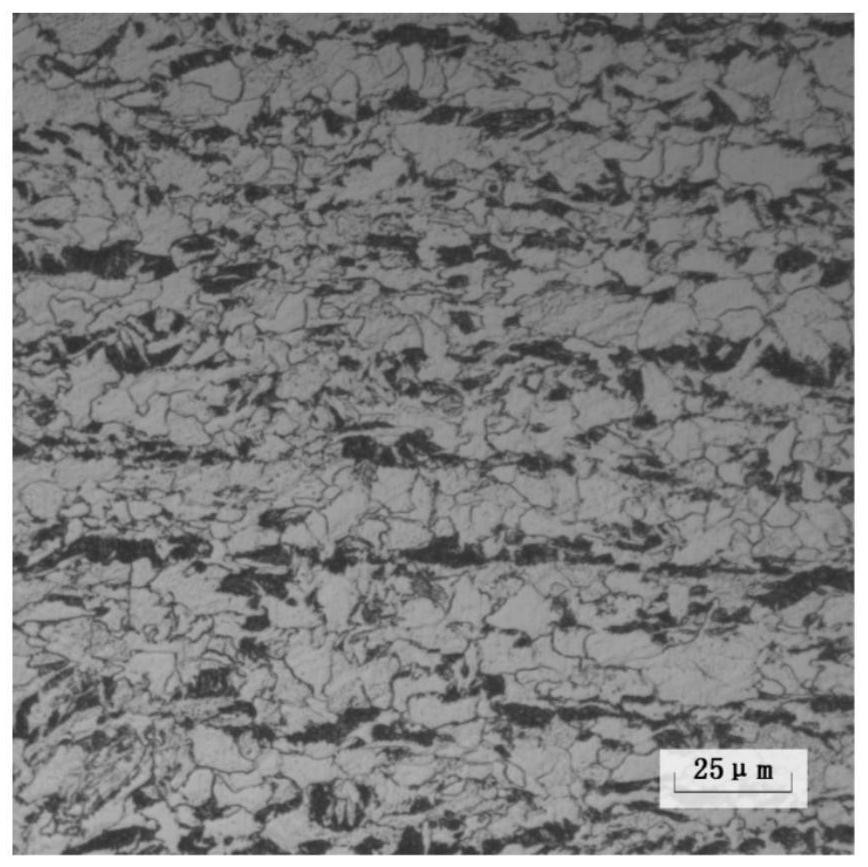

Embodiment 2

[0064] The thickness of the steel plate is 50mm, and the yield strength of the steel plate is 370MPa.

[0065] The chemical composition of the steel plate is designed according to mass percentage: C=0.09%, Si=0.25%, Mn=1.50%, P=0.010%, S=0.0010%, Cr=0.10%, Nb=0.03%, Ti=0.015%, The balance is Fe and other unavoidable impurities, and common precious elements such as Ni, Cu, V and Mo are not intentionally added.

[0066] The key process steps and parameters of steel plate thermomechanical rolling are as follows:

[0067] (1) Slab heating: the heating temperature of the slab is 1200°C, a 400mm continuous casting slab is selected, and the slab is in the furnace for 440 minutes;

[0068] (2) Controlled rolling: after the steel billet leaves the heating furnace, it enters the descaler for descaling, such as rough rolling in the rough rolling mill, the maximum pass reduction rate is 18.0%, and the thickness of the waiting temperature is 130mm. Swing air cooling between passes; model...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com