Two-dimensional carbon nanosheet with thickness capable of being accurately controlled and preparation method thereof

A precise control, carbon nanosheet technology, applied in the field of materials, to achieve the effect of simplifying the assembly process, simple steps and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

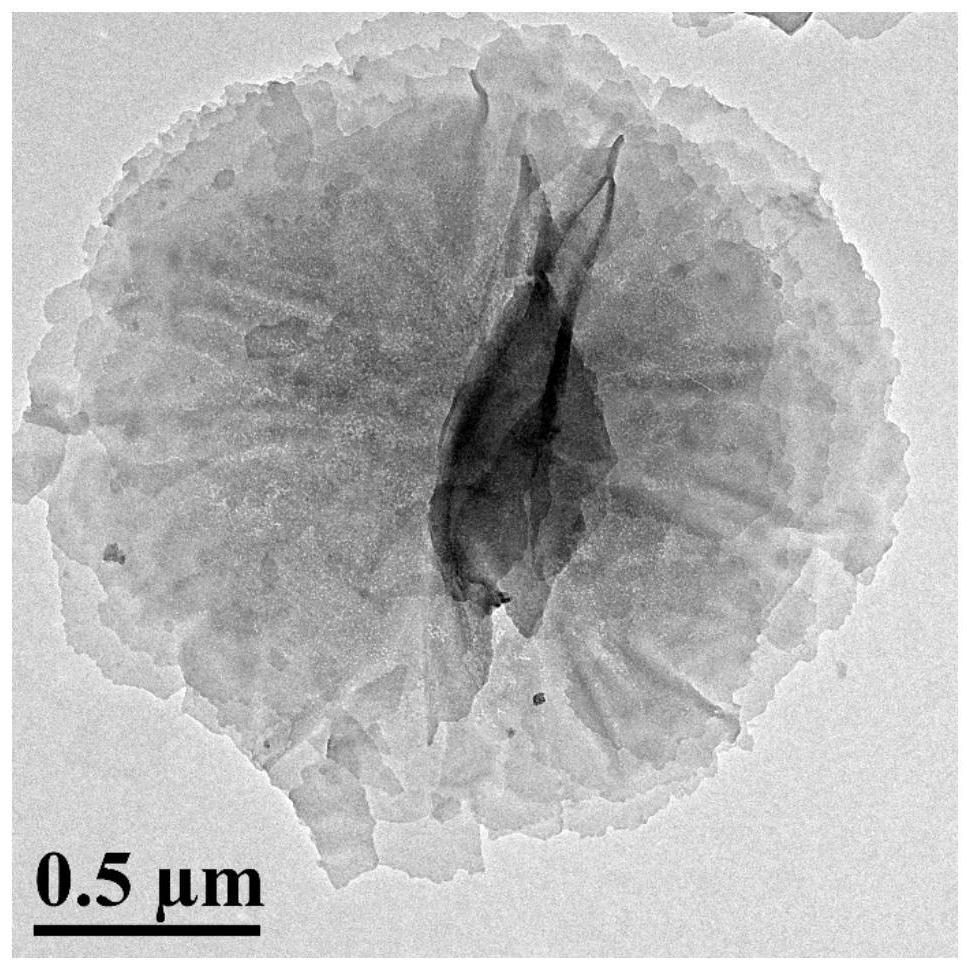

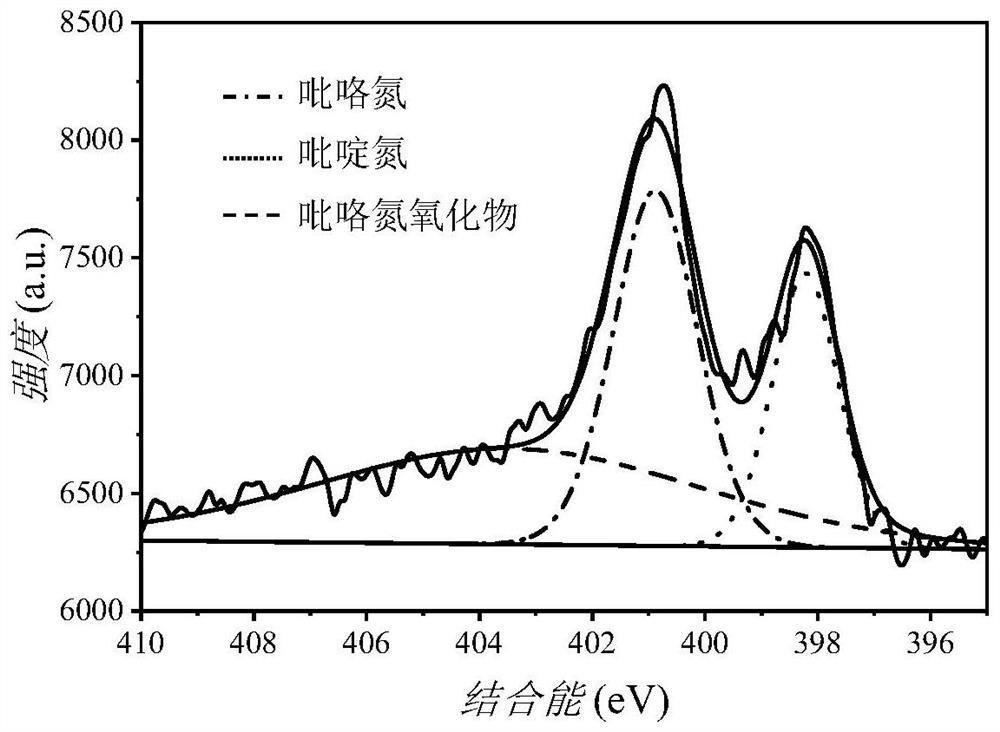

[0038] This embodiment provides a two-dimensional carbon nanosheet whose thickness can be precisely controlled and its preparation method. The thickness of the carbon nanosheet whose thickness can be precisely regulated can be precisely regulated within the range of 5.1-92.3nm, and has good dispersibility, Intrinsic nitrogen doping with high specific surface area and atomically uniform distribution. The preparation method comprises the following steps:

[0039] (1) Preparation steps of two-dimensional polymer nanosheets whose thickness can be precisely controlled:

[0040] 1000 mg of amphiphilic alternating copolymer was dissolved in dimethylformamide (DMF) at a concentration of 20 mg / mL, the polymer solution was heated to 155 ° C in an oil bath, and kept at this temperature for 5 minutes, Cool to room temperature to obtain a dispersion containing two-dimensional polymer nanosheets. The dispersion was centrifuged, and the precipitate was washed three times with deionized wat...

Embodiment 2

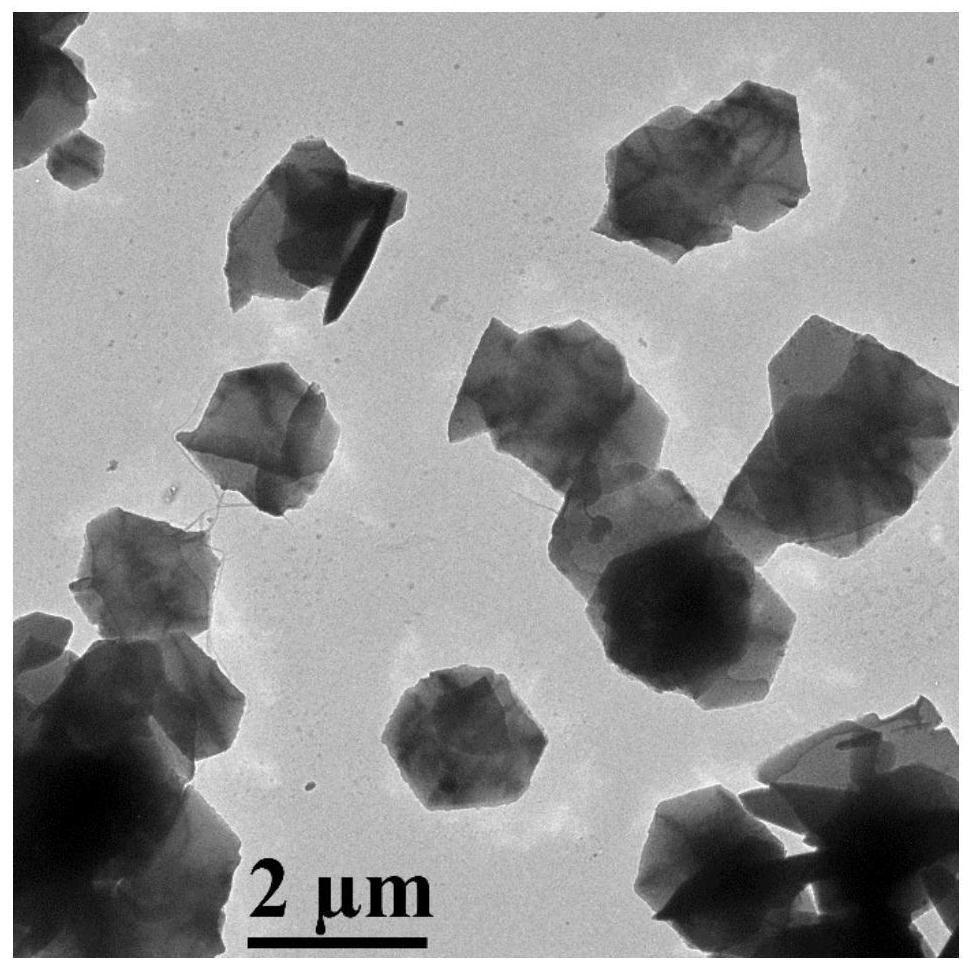

[0045] This embodiment provides a two-dimensional carbon nanosheet whose thickness can be precisely controlled and a preparation method thereof. The preparation method includes the following steps:

[0046] (1) Preparation steps of two-dimensional polymer nanosheets whose thickness can be precisely controlled:

[0047] 1000 mg of amphiphilic alternating copolymer was dissolved in dimethylformamide (DMF) at a concentration of 30 mg / mL, the polymer solution was heated to 155 ° C in an oil bath, and kept at this temperature for 15 minutes, Cool to room temperature to obtain a dispersion containing two-dimensional polymer nanosheets. The dispersion was centrifuged, and the precipitate was washed three times with absolute ethanol, and dried in a vacuum oven for 24 hours to obtain a two-dimensional polymer nanosheet (in powder form) with a thickness of 13.2 nm.

[0048] (2) Preparation steps of two-dimensional carbon nanosheets whose thickness can be precisely controlled:

[0049]...

Embodiment 3

[0051] This embodiment provides a two-dimensional carbon nanosheet whose thickness can be precisely controlled and a preparation method thereof. The preparation method includes the following steps:

[0052] (1) Preparation steps of two-dimensional polymer nanosheets whose thickness can be precisely controlled:

[0053] 1000 mg of amphiphilic alternating copolymer was dissolved in dimethylformamide (DMF) at a concentration of 50 mg / mL, the polymer solution was heated to 155 ° C in an oil bath, and kept at this temperature for 20 minutes, Cool to room temperature to obtain a dispersion containing two-dimensional polymer nanosheets. The dispersion was centrifuged, and the precipitate was washed 3 times with acetone, and dried in a vacuum oven for 24 hours to obtain a two-dimensional polymer nanosheet (in powder form) with a thickness of 38.6 nm.

[0054] (2) Preparation steps of two-dimensional carbon nanosheets whose thickness can be precisely controlled:

[0055] Under the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com