Application of mixture of carbon material and ionic bromide and aqueous zinc-bromine double-ion battery

A bromide and ion-type technology, applied in the field of electrochemistry, can solve the problems of hindering the normal deposition and dissolution of zinc, poor cycle performance, poor kinetics, etc., and achieve high efficiency and reversibility of the deposition and dissolution process, long cycle life and stable operation Sexual, efficient and reversible deposition and dissolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

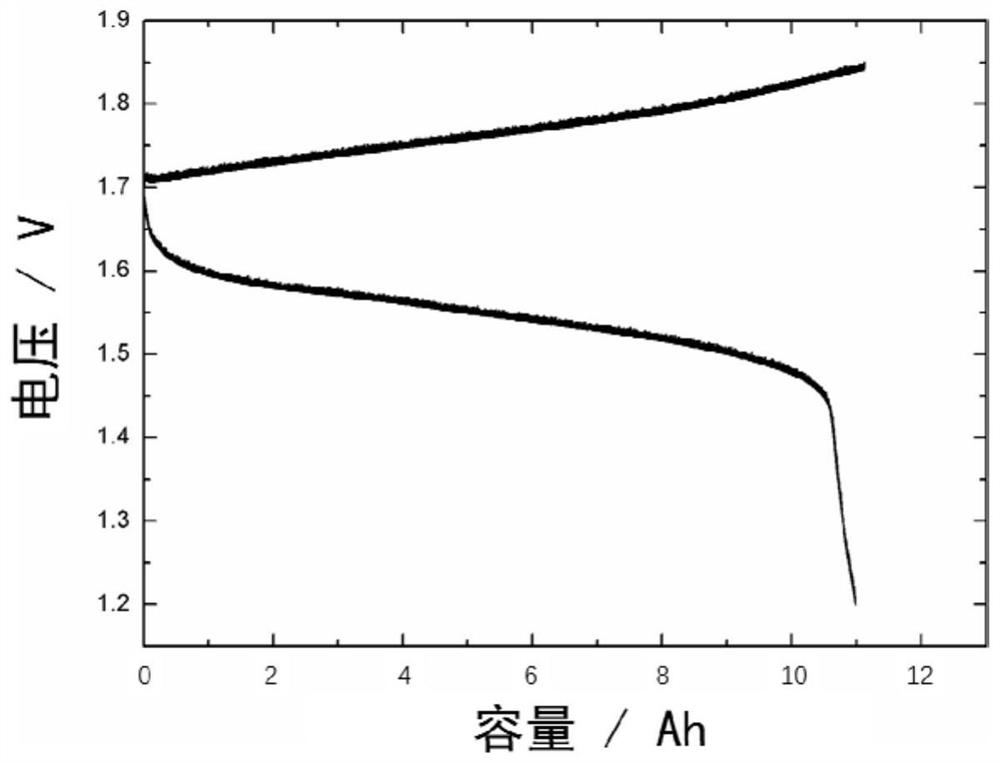

Embodiment 1

[0041] This embodiment provides a Zn | saturated ZnCl 2 Aqueous solution|ZnBr 2 - Natural graphite battery. The negative electrode active material of the battery is metal Zn foil with a thickness of 0.1mm. The electrolyte is configured at 25°C: add 432g ZnCl to 100g pure water 2 Get saturated ZnCl 2 After the aqueous solution, an additional 21.5 g of ZnCl was added 2 , to get supersaturated ZnCl 2 aqueous solution. Cathode ZnBr 2 1. A thin film electrode made by uniformly mixing natural graphite powder (particle size less than 10um) and PTFE binder at a mass ratio of 1.27:1:0.1 (the molar ratio of bromine atoms to carbon atoms in graphite is 0.95:7). When assembling the battery, the film-shaped positive electrode, glass fiber separator (trade name: Whatman) and metal Zn foil are sequentially sandwiched in the air, and the electrolyte solution (4g / Ah) is added dropwise to the glass fiber separator to completely soak it. Positive and negative electrodes, after which the ...

Embodiment 2

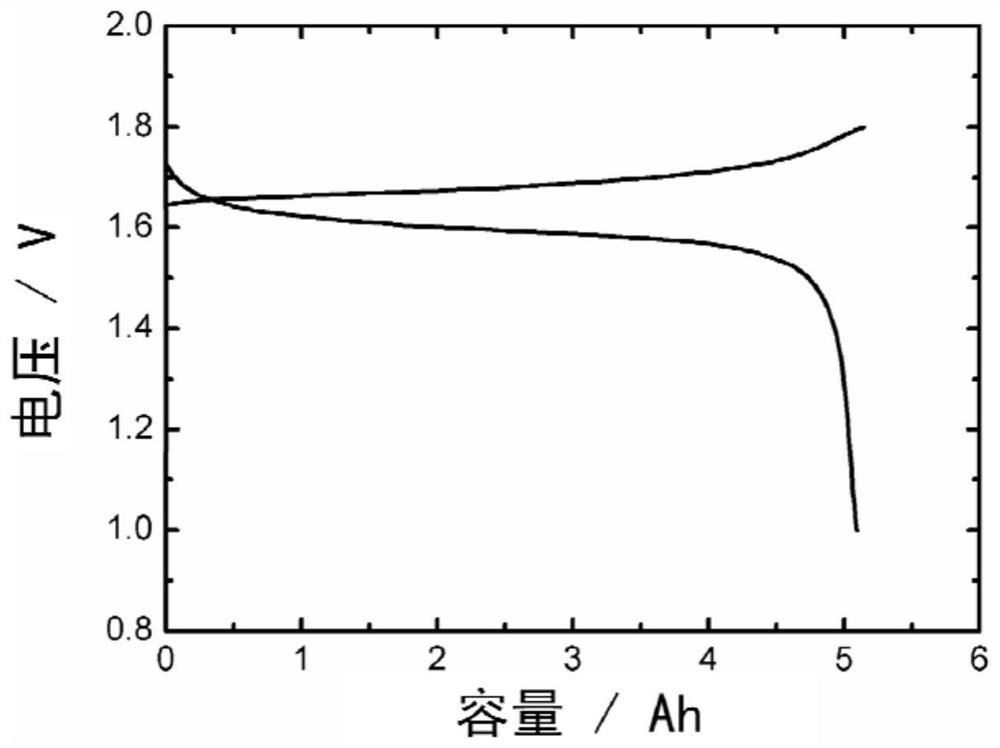

[0044] This embodiment provides a Zn|ZnCl 2 Saturated Aqueous Solution | NaBr-Natural Graphite Battery. The active material of the negative electrode of the battery is galvanized copper foil, the thickness of the copper foil is 10um, and the thickness of the galvanized layer is about 5um. The electrolyte configuration process is the same as in Example 1. The positive electrode is a film made by uniformly mixing NaBr, natural graphite powder (particle size less than 10um) and PVDF binder at a mass ratio of 1.16:1:0.1 (the molar ratio of bromine atoms to carbon atoms in graphite is 0.95:7) electrode. When assembling the battery, a film-shaped positive electrode, glass fiber separator (trade name: Whatman) and galvanized copper foil are sequentially sandwiched in the air, and an electrolyte solution (7.1g / Ah) is added dropwise to the glass fiber separator to make it The positive and negative electrodes were completely wetted, after which the battery was sealed and the electroc...

Embodiment 3

[0047] This embodiment provides a Zn | saturated ZnCl 2 Aqueous solution|MgBr 2 - Natural graphite battery. The active material of the negative electrode of the battery is galvanized copper foil, the thickness of the copper foil is 10um, and the thickness of the galvanized layer is about 5um. The electrolyte configuration process is the same as in Example 1. Cathode MgBr 2 1. A thin film electrode made by uniformly mixing natural graphite powder (particle size less than 10um) and PVDF binder at a mass ratio of 1.04:1:0.1 (the molar ratio of bromine atoms to carbon atoms in graphite is 0.95:7). When assembling the battery, a film-shaped positive electrode, glass fiber separator (trade name: Whatman) and galvanized copper foil are sequentially sandwiched in the air, and an electrolyte solution (7.1g / Ah) is added dropwise to the glass fiber separator to make it The positive and negative electrodes were completely wetted, after which the battery was sealed and the electrochemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com