Packaging structure of fuel cell membrane electrode assembly and manufacturing method and application thereof

A membrane electrode assembly and fuel cell membrane technology, applied in the field of materials, can solve the problems affecting the electrochemical performance of fuel cells, the performance of fuel cells needs to be improved, and unfavorable compression and stacking of other structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0049] The present invention is accomplished based on the following findings of the inventors:

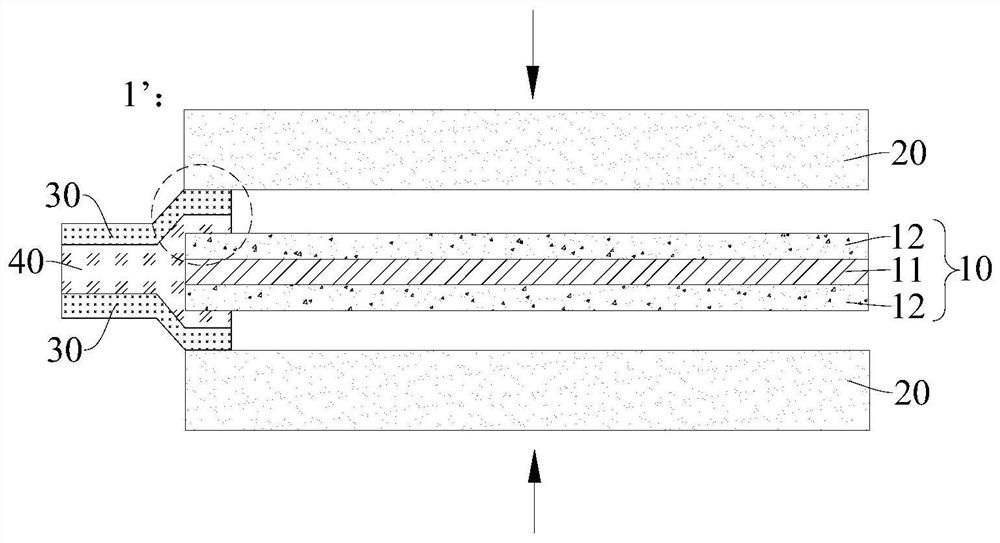

[0050] In the related art, refer to figure 1 The packaging structure 1' of the fuel cell membrane electrode assembly includes a membrane electrode assembly 10, the membrane electrode assembly 10 includes a proton exchange membrane 11, and an electrode layer 12; a gas diffusion layer 20; a sealing frame, the sealing frame includes a frame 30 and an adhesive layer 40. However, the packaging structure 1' of the fuel cell membrane electrode assembly in the related art will be subjected to external pressure during the stacking and compression process to form the fuel cell product, wherein the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com