Packaging structure for luminescent device

A light-emitting device and packaging structure technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of ineffective expansion of the viewing angle range of the optical path, reduced utilization rate of the light-emitting device, waste, etc., to achieve the best visual brightness, Effect of increasing electric power and reducing fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

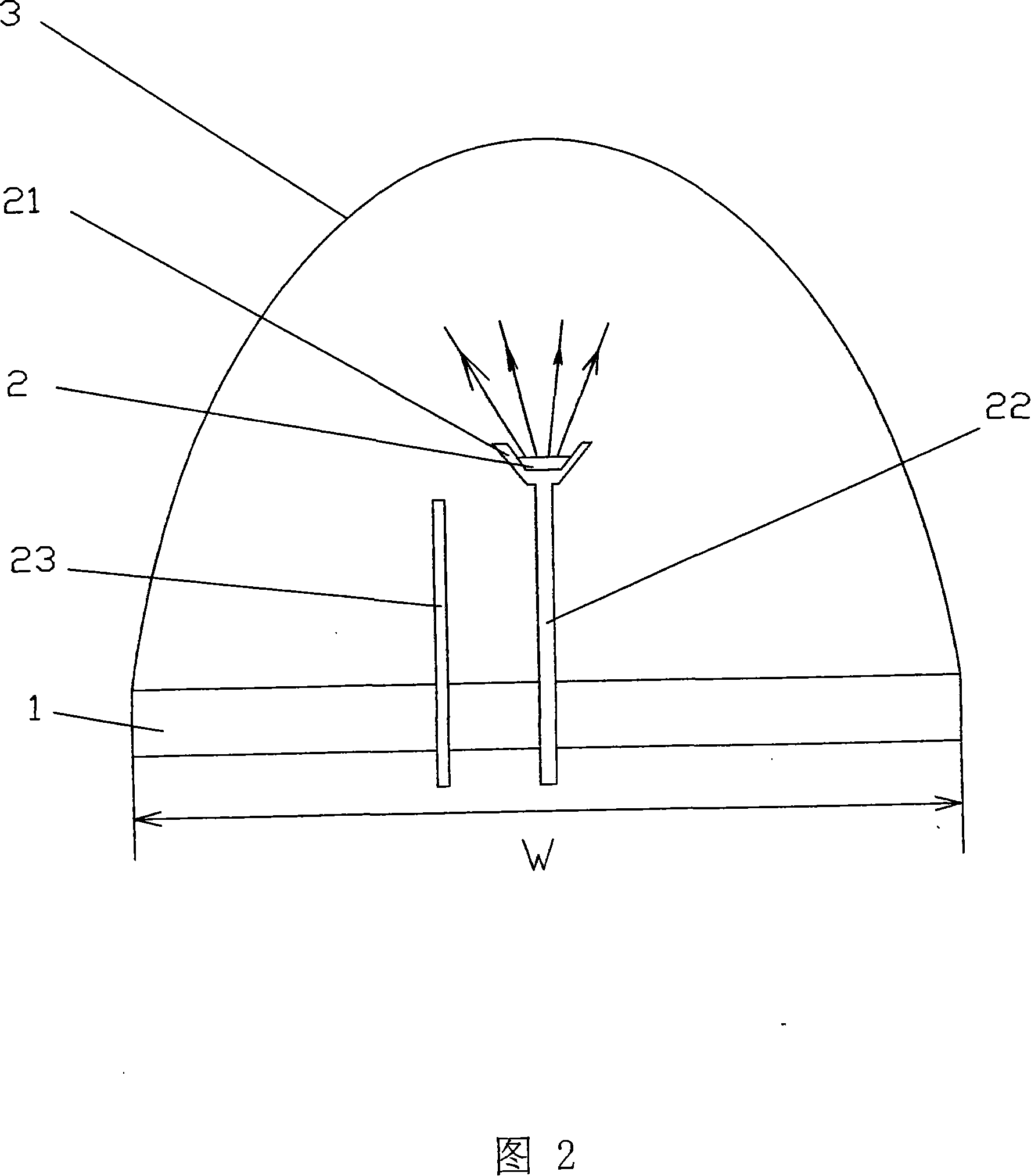

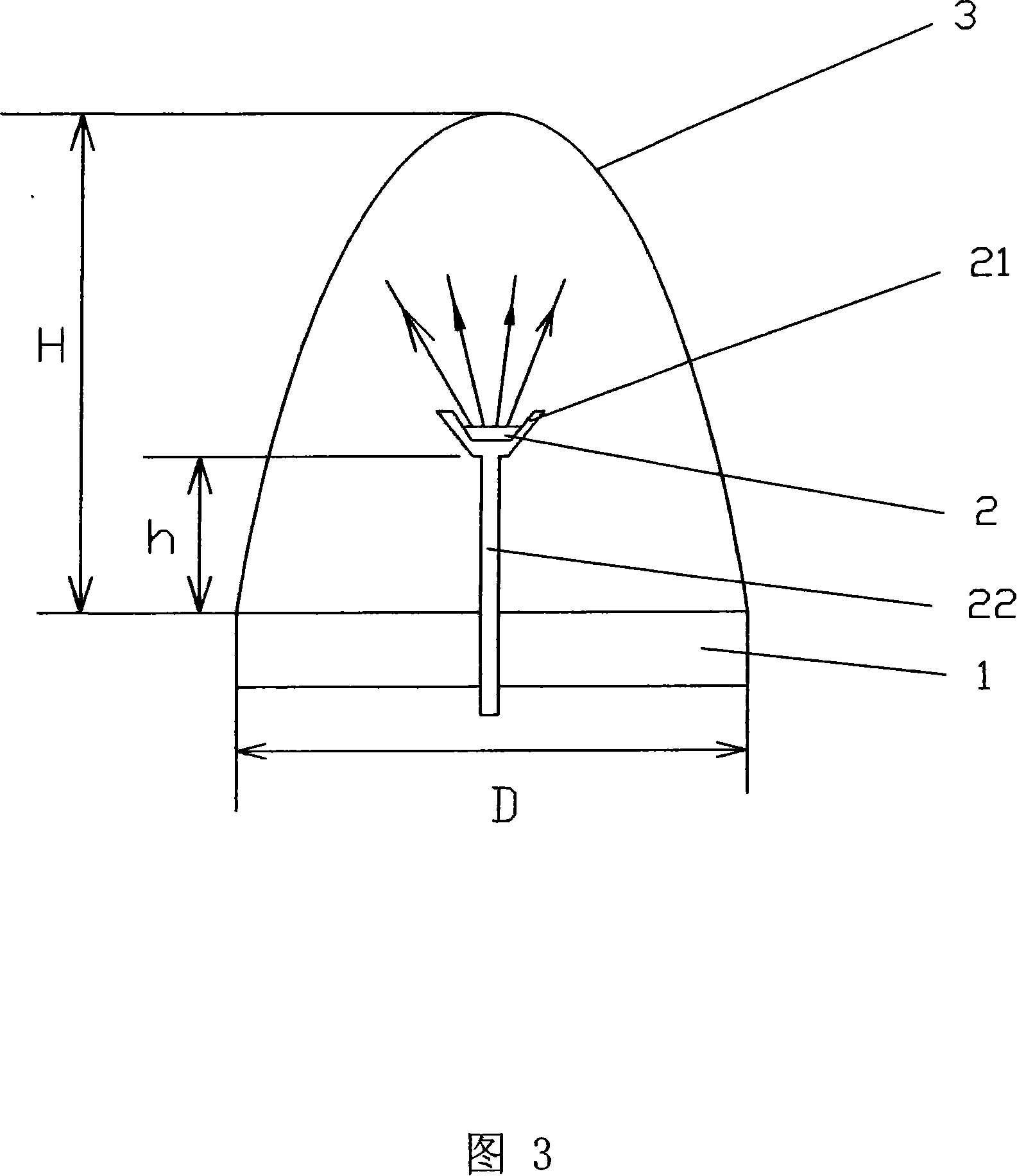

[0037] In the packaging structure of the light-emitting device, the total height H of the diode housing 3 is preferably 7MM, the length W of the diode housing 3 in the horizontal direction is preferably 3.9MM, and the width D of the diode housing 3 in the vertical direction is The most is 3.1MM.

[0038] As shown in Figure 4, when the light emission angle a of the light emitting diode chip 2 in the horizontal direction is 100 degrees and the light emission angle a in the vertical direction is 40 degrees, the light emitting diode chip 2 and the tube base The best distance h between 1 is 4.5MM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com