Distributed type non-slippage optical fiber strain sensor and manufacturing method thereof

A fiber optic strain and sensor technology, which is applied in the direction of instruments, optical devices, and optical testing of defects/defects, can solve the problems that the test results cannot accurately reflect the actual strain distribution of the structure, the internal slip of the optical fiber, etc., and achieve the elimination of internal slip, Easy on-site installation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

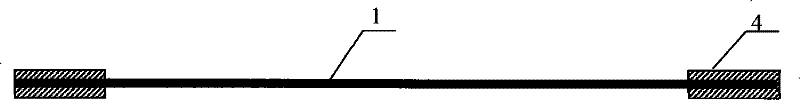

[0069] Embodiment 1 fully bonded optical fiber strain sensor

[0070] The single-mode optical fiber used in the strain sensor of this embodiment is a sheet with a width of 1.5-6mm and a thickness of 0.5mm-1mm, or a wire with a diameter of 1-2mm. In this embodiment, due to the price advantage of basalt fiber, especially the linear expansion coefficient of basalt fiber is close to that of concrete, the long-term test performance is stable, and it is more suitable for monitoring the long-term state of concrete structure, so basalt fiber is selected as the packaging material. The structure of the sensor is that the bare optical fiber 1 is covered by the basalt fiber encapsulation layer 7 to form protection for the bare optical fiber 1, and the encapsulated optical fiber sensor is divided into a test section and a connection section. In the test section, the bare optical fiber 1 with the coating layer stripped off is used. The bare optical fiber and the basalt fiber are infiltrated...

Embodiment 2

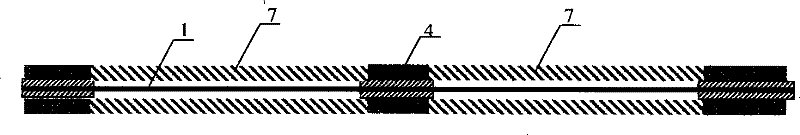

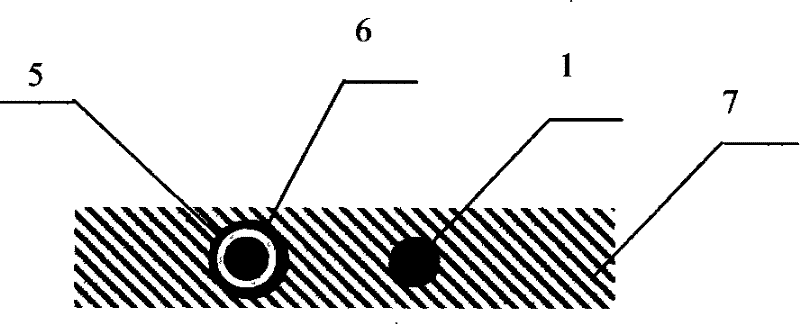

[0079] Embodiment 2 Internal fixed-point fiber optic sensor

[0080] The single-mode optical fiber used in the optical fiber strain sensor of this embodiment is a sheet with a width of 1.5-6mm and a thickness of 0.5mm-1mm, or a wire with a diameter of 1-2mm. The package adopts basalt fiber, and the structure of the strain sensor is that the single-mode optical fiber 4 is pierced with multiple sleeves 6, and the sleeves 6 are arranged at a certain distance, and the bare optical fiber 1 and the sleeves 6 between the sleeves are bonded with epoxy resin 3 On the impregnated basalt bundle 7, the sleeve 6 not only protects the single-mode optical fiber 4, but also ensures the free deformation of the single-mode optical fiber 4 in the sleeve 6, so that the gauge length between two bonding points can be tested The average strain within the range changes the distributed optical fiber into a plurality of continuous long-gauge-length strain sensors 41, which are also relatively convenien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com