A lithium-ion battery negative electrode based on lithium tetrathiofulvalene dicarboxylate and preparation method thereof

A technology of lithium tetrathiofulvalene dicarboxylate and tetrathiofulvalene dicarboxylic acid, applied in the field of lithium ion battery materials, can solve problems such as complicated preparation process, and achieve good conductivity and excellent cycle stability , the effect of conjugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

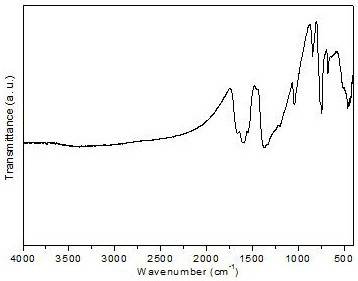

[0037] The preparation of embodiment 1 tetrathiofulvalene dicarboxylate methyl ester

[0038] Add 10 mL (0.165 mol) of carbon disulfide and 8.4 g (0.1 mol) of methyl propiolate as raw materials into 80 mL of anhydrous tetrahydrofuran, then add 20.2 g (0.1 mol) of catalyst tributylphosphine, under argon protection, in Reaction at -76 °C for 4 hours, vacuum drying at 80 °C for 6 hours after suction filtration, the crude product was chromatographed with a mixed solvent of cyclohexane and dichloromethane with a volume ratio of 2:1 to obtain tetrathiofulvalene di Methyl carboxylate 2.1 g.

Embodiment 2 4

[0039] The preparation of embodiment 2 tetrathiofulvalene dicarboxylic acids

[0040] Add 0.64 g (2 mmol) methyl tetrathiofulvalene dicarboxylate and 0.2 g (5 mmol) sodium hydroxide to 40 mL equal volume tetrahydrofuran and water mixed solvent, react at 90 °C for 4 hours, Cool to room temperature, remove THF by rotary evaporation, add aqueous hydrochloric acid to adjust the pH to 5, collect the precipitate by filtration, and vacuum-dry at 100 °C for 24 hours to obtain 0.54 g of tetrathiofulvalenedicarboxylic acid.

Embodiment 3 4

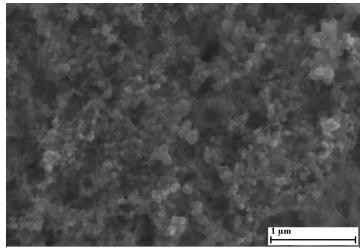

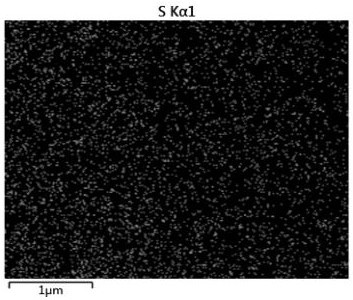

[0041] The preparation of embodiment 3 tetrathiofulvalene dicarboxylate lithium

[0042] Add 0.05 g (2.1 mmol) of lithium hydroxide to 20 mL of deionized water, then add 0.29 g (1 mmol) of tetrathiofulvalene dicarboxylic acid into the lithium hydroxide aqueous solution, stir at room temperature for 2 hours, and then The solution was freeze-dried for 24 hours to obtain 0.28 g of lithium tetrathiofulvalene dicarboxylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com