Equipment and method for preparing perovskite material based on atomization gas-liquid-solid thermal deposition method

A perovskite material, atomizing gas technology, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc. Problems such as low utilization rate, high equipment and operating costs, etc., are beneficial to carrier transport, reducing interface recombination, and saving equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

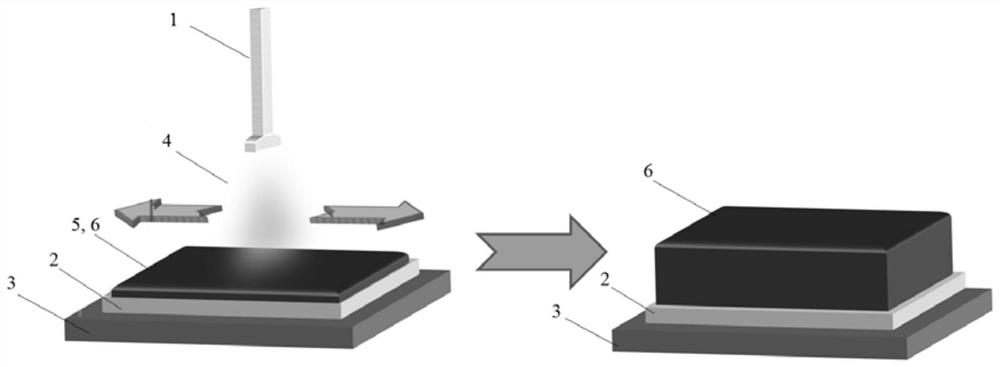

[0049] figure 1 A schematic diagram showing the device and method for preparing perovskite materials based on the atomization thermal deposition method of the present invention. The atomizing part 1 (which is in the form of a nozzle 1 in the figure) continuously atomizes the perovskite material precursor solution obtained by dissolving the perovskite material precursor in a solvent to produce perovskite material precursor atomization Stream 4. The atomized flow 4 of the precursor of the perovskite material is continuously deposited on the deposition part 2 located below the atomization part 1 under the action of gravity to form a deposit 5 of the precursor of the perovskite material including a solvent. At the same time, the heating unit 3 located below the deposition unit 2 continuously heats the deposition unit 2 , so that the perovskite material precursor 5 containing the solvent is formed, and the solvent is volatilized to grow the perovskite material 6 .

[0050] Atomiz...

Embodiment 2

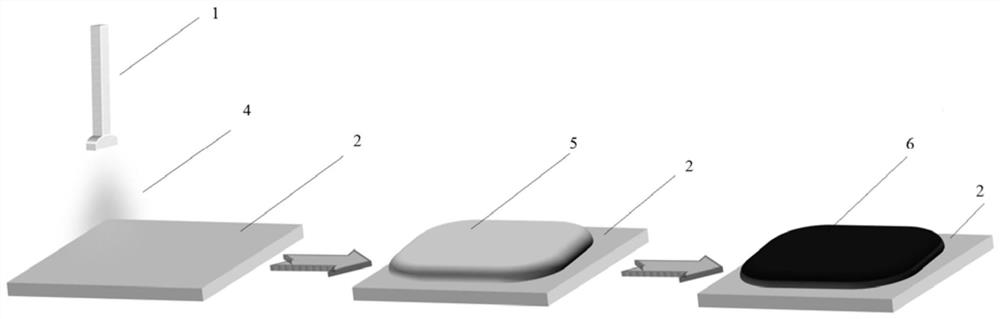

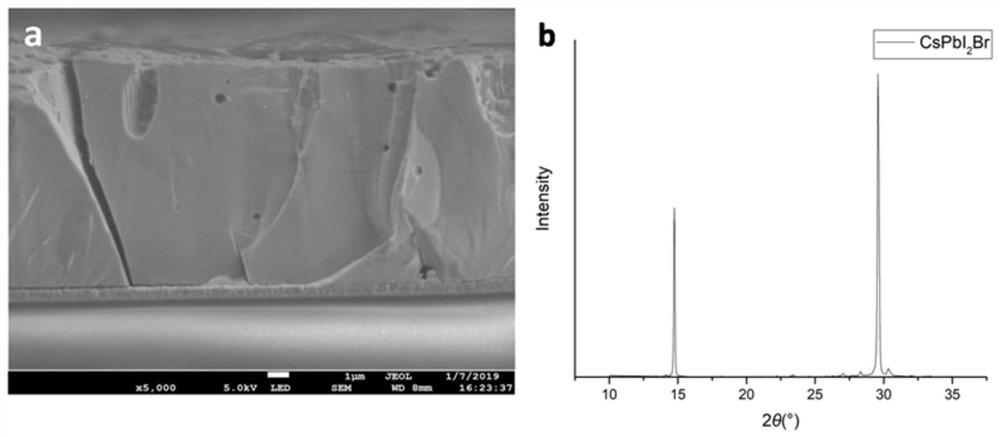

[0056] This example illustrates the preparation of CsPbI by using the equipment and method for preparing perovskite materials based on the atomization gas-liquid solid-thermal deposition method of the present invention 2 Br inorganic perovskite film.

[0057] Weigh 10mmol CsBr powder, 10mmol PbI 2 powder, after it is mixed evenly, be dissolved in 20mL DMSO and DMF mixed solvent (the volume ratio of DMSO and DMF is 5), prepare CsPbI 2 Br precursor solution.

[0058] refer to figure 1 The device shown, makes CsPbI through nozzle 1 2 Continuous atomization of Br precursor solution to form CsPbI 2 Br perovskite precursor atomization flow 4. The atomized flow 4 is deposited on the deposition part 2 below the nozzle 1 under the drive of gravity or gravity and pressurized gas flow, forming a solvent-containing CsPbI 2 Br precursor deposit 5. At the same time, the deposition part 2 is continuously heated at a temperature of 200 ° C by the heating part 3 below the deposition par...

Embodiment 3

[0061] This example illustrates the preparation of MAPbI by using the equipment and method for preparing perovskite materials based on the atomization gas-liquid solid-thermal deposition method of the present invention 3 Organic-inorganic hybrid perovskite films.

[0062] Weigh 10mmol MAI powder, 10mmol PbI 2 Powder, after it is mixed homogeneously, be dissolved in 20mL DMSO and DMF mixed solvent (the volume ratio of DMSO and DMF is 5), prepare MAPbI 3 precursor solution.

[0063] refer to figure 1 The device shown, makes MAPbI through nozzle 1 3 The precursor solution is continuously atomized to form CsPbI 2 Br perovskite precursor atomization flow 4. The atomized flow 4 is deposited on the deposition part 2 below the nozzle 1 under the drive of gravity or gravity and pressurized gas flow, forming a MAPbI containing solvent 3 Precursor deposit 5. At the same time, the deposition part 2 is continuously heated at a temperature of 200 ° C by the heating part 3 below the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com