Sphalerite flotation composite inhibitor and application thereof

A compound inhibitor and sphalerite technology, which is applied in flotation, solid separation, etc., can solve problems such as environmental pollution, low production index, and large chemical consumption, and achieve high inhibition selectivity, broad application prospects, and increased affinity. water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

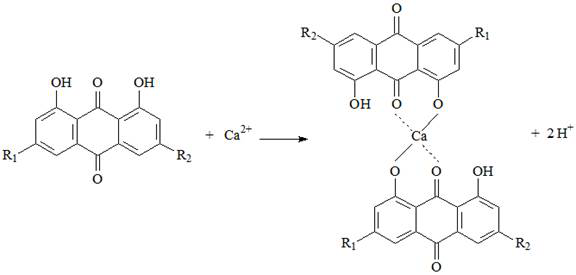

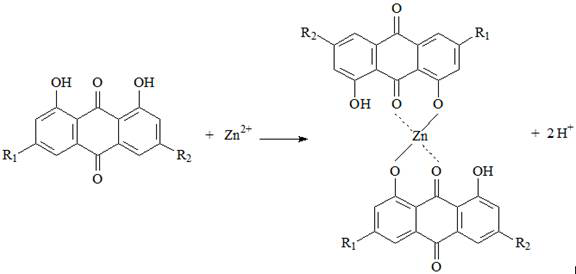

Method used

Image

Examples

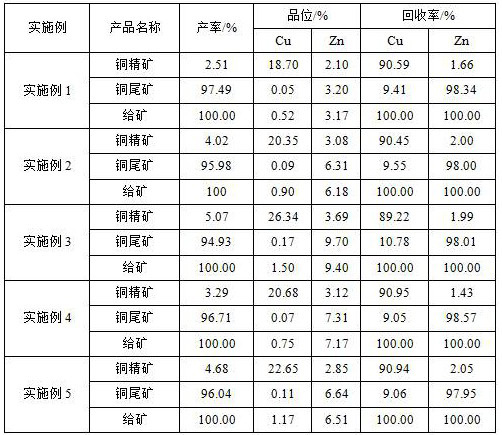

Embodiment 1

[0034] A sphalerite flotation composite inhibitor, the composite inhibitor includes an organic inhibitor and an inorganic inhibitor; the organic inhibitor is emodin, and the inorganic inhibitor is ZnSO 4 and CaO, the mass ratio of organic inhibitor to inorganic inhibitor is 1:4, the ZnSO 4 The mass ratio of CaO and CaO is 1:1, the total dosage of composite inhibitor is 750g / t, and the composite inhibitor is added to the pulp during flotation.

[0035]The above composite inhibitor is used for the separation of sphalerite and chalcopyrite during flotation of copper-zinc sulfide ore:

[0036] In the copper-zinc sulfide ore processed in this embodiment: Cu grade is 0.52wt%, Zn grade is 3.17wt%, copper-bearing minerals are mainly chalcopyrite, and zinc-bearing minerals are mainly sphalerite, and the flotation steps are as follows:

[0037] (1) Grind the copper-zinc sulfide ore to a grinding fineness of -0.074mm, accounting for 90%, adjust the concentration of the pulp concentratio...

Embodiment 2

[0044] A sphalerite flotation composite inhibitor, the composite inhibitor includes an organic inhibitor and an inorganic inhibitor; the organic inhibitor is chrysophanol, and the inorganic inhibitor is ZnSO 4 and Na 2 S 2 O 5 , the mass ratio of organic inhibitor to inorganic inhibitor is 1:5, the ZnSO 4 and Na 2 S 2 O 5 The mass ratio of 1:2, the total dosage of the composite inhibitor is 1620g / t, and the composite inhibitor is added to the pulp during flotation.

[0045] The above composite inhibitor is used for the separation of sphalerite and chalcopyrite during flotation of copper-zinc sulfide ore:

[0046] In the copper-zinc sulfide ore processed in this example: Cu grade is 0.90wt%, Zn grade is 6.13wt%, copper-bearing minerals are mainly chalcopyrite, and zinc-bearing minerals are mainly sphalerite.

[0047] The grinding fineness of the copper-zinc sulfide ore is -0.074mm, accounting for 80%, and the concentration of the pulp is adjusted to 30%. The pH of the pu...

Embodiment 3

[0055] A sphalerite flotation composite inhibitor, the composite inhibitor includes an organic inhibitor and an inorganic inhibitor; the organic inhibitor is rhein, and the inorganic inhibitor is ZnSO 4 and Na 2 CO 3 , the mass ratio of organic inhibitor to inorganic inhibitor is 1:3, the ZnSO 4 and Na 2 CO 3 The mass ratio of the composite inhibitor is 1:4, the total dosage of the composite inhibitor is 2100g / t, and the composite inhibitor is added to the pulp during flotation.

[0056] The above composite inhibitor is used for the separation of sphalerite and chalcopyrite during flotation of copper-zinc sulfide ore:

[0057] In the copper-zinc sulfide ore processed in this example: the grade of Cu is 1.5wt%, the grade of Zn is 9.45wt%, the copper-bearing minerals are mainly chalcopyrite, and the zinc-bearing minerals are mainly sphalerite, and the flotation conditions are as follows:

[0058] (1) Grind the copper-zinc sulfide ore to a grinding fineness of -0.074mm, acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com