K1.28Ti8O16, composite carbon nanofiber, preparation method of composite carbon nanofiber and application of composite carbon nanofiber in sodium-ion battery

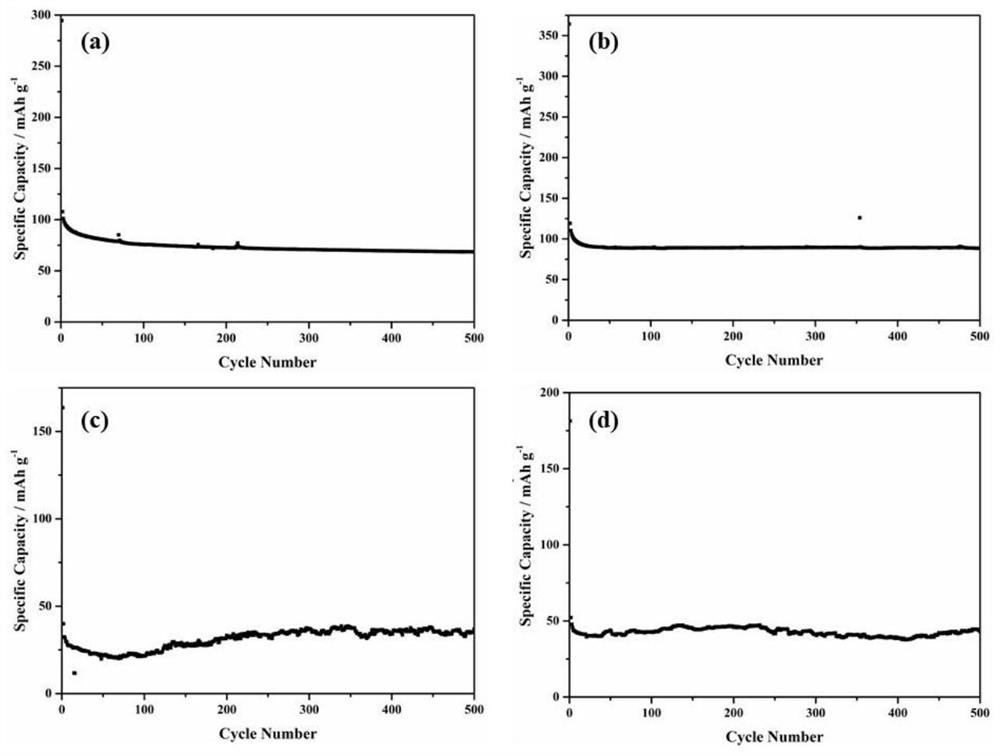

A k1.28ti8o16, nanofiber technology, applied in the chemical characteristics of fibers, circuits, negative electrodes, etc., can solve the problems of lack of negative active materials, long-term cycle stability of electrochemical performance, etc., to achieve excellent long-term cycle stability, The effect of excellent crystal phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

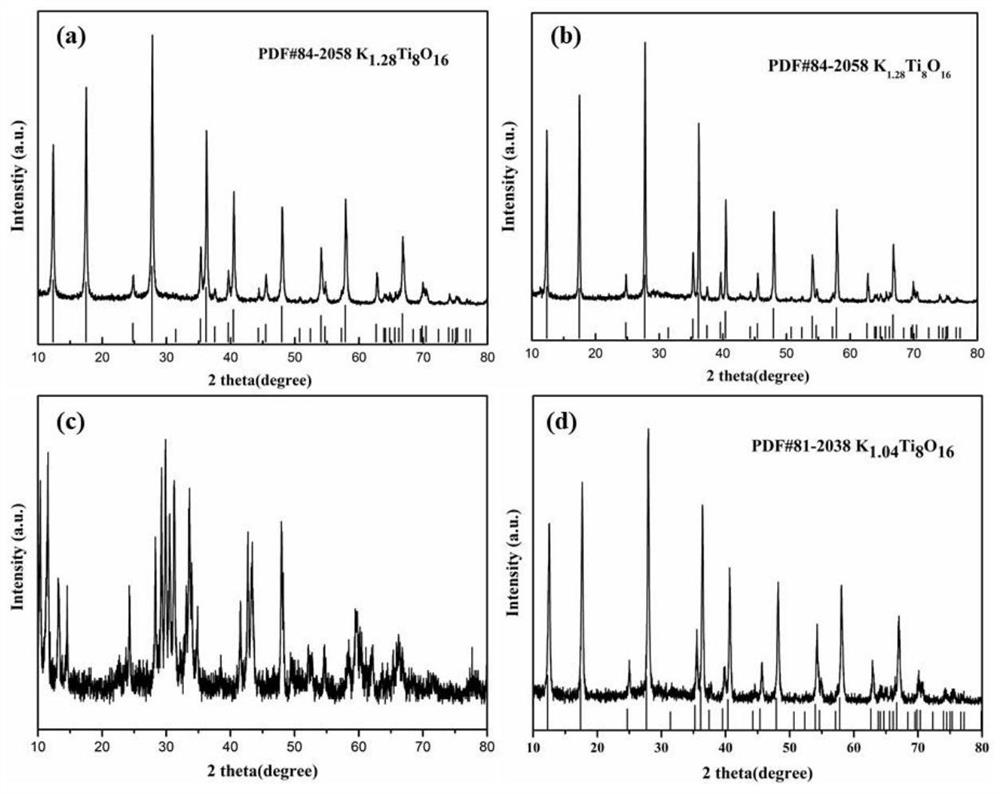

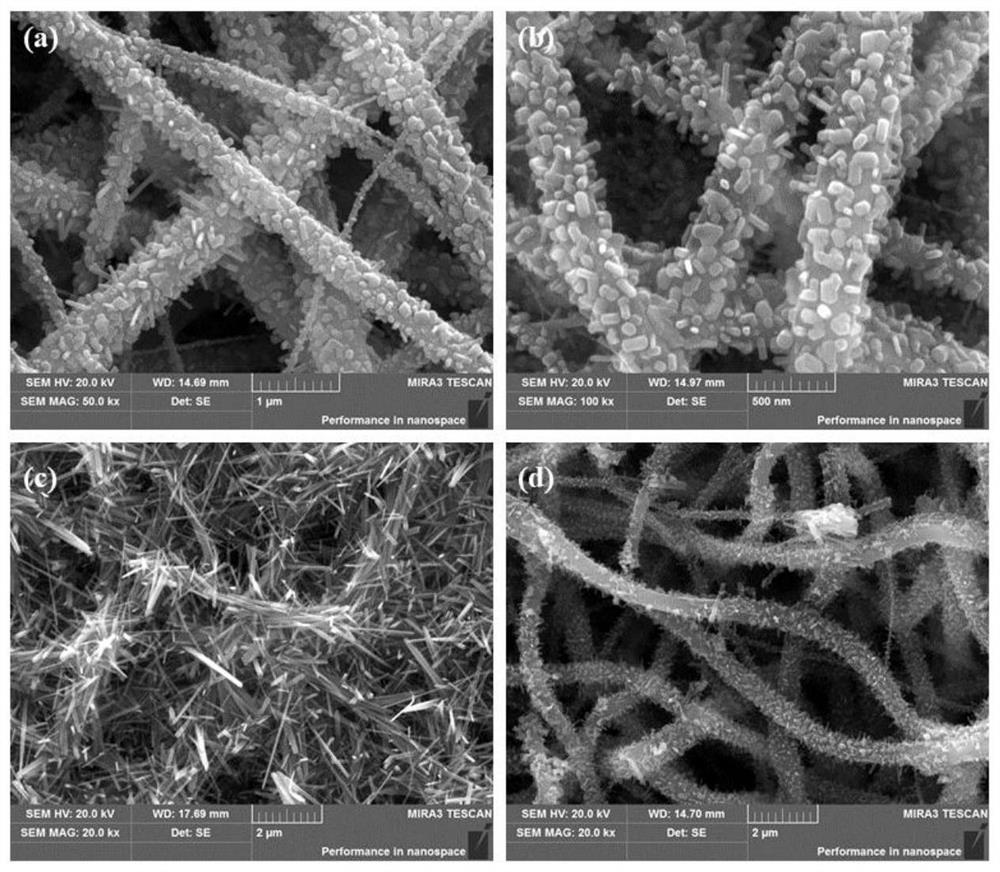

Embodiment 1

[0071] 1) Preparation of precursor solution: Mix 8g ethanol, 2.4g acetic acid, and 2.85g tetrabutyl titanate at 20-25°C to obtain a mixed solvent, and add an appropriate amount of CH 3 COOK (K / Ti molar ratio is 1:3.0), magnetic stirring at 500rpm at room temperature for 30min to make CH 3 COOK was completely dissolved; then 1 g of polyvinylpyrrolidone was added, and magnetically stirred at the same rotational speed for 12 hours to obtain an electrospinning precursor solution.

[0072] 2) Electrospinning: extract 15ml of precursor solution with a medical syringe, and use a No. 20 flat-mouth stainless steel needle to spin on an electrospinning device. The nanofibers obtained by spinning are received by aluminum foil; the distance between the needle and the receiving plate is 22cm , the spinning voltage is 20KV, the ambient temperature is 25°C, the humidity is 30%, and the feeding speed is 0.8ml / h.

[0073] 3) The nanofibers obtained by spinning were pre-carbonized in a muffle f...

Embodiment 2

[0079] 1) Preparation of precursor solution: Mix 8g ethanol, 2.4g acetic acid, and 2.85g tetrabutyl titanate at 20-25°C to obtain a mixed solvent, and add an appropriate amount of CH 3 COOK (K / Ti molar ratio is 1:2.5), magnetic stirring at 500rpm for 30min to make CH 3 COOK was completely dissolved; then 1 g of polyvinylpyrrolidone was added, and magnetically stirred at the same rotational speed for 12 hours to obtain an electrospinning precursor solution.

[0080] 2) Electrospinning: extract 15ml of precursor solution with a medical syringe, and use a No. 20 flat-mouth stainless steel needle to spin on an electrospinning device. The nanofibers obtained by spinning are received by aluminum foil; the distance between the needle and the receiving plate is 22cm , the spinning voltage is 20KV, the ambient temperature is 25°C, the humidity is 30%, and the feeding speed is 0.8ml / h.

[0081] 3) The nanofibers obtained by spinning were pre-carbonized in a muffle furnace (air atmosphe...

Embodiment 3

[0087] 1) Preparation of precursor solution: Mix 8g ethanol, 2.4g acetic acid, and 2.85g tetrabutyl titanate at 20-25°C to obtain a mixed solvent, and add an appropriate amount of CH 3 COOK (K / Ti molar ratio is 1:3.5), magnetic stirring at 500rpm for 30min to make CH 3 COOK was completely dissolved; then 1 g of polyvinylpyrrolidone was added, and magnetically stirred at the same rotational speed for 12 hours to obtain an electrospinning precursor solution.

[0088] 2) Electrospinning: extract 15ml of precursor solution with a medical syringe, and use a No. 20 flat-mouth stainless steel needle to spin on an electrospinning device. The nanofibers obtained by spinning are received by aluminum foil; the distance between the needle and the receiving plate is 22cm , the spinning voltage is 20KV, the ambient temperature is 25°C, the humidity is 30%, and the feeding speed is 0.8ml / h.

[0089] 3) The nanofibers obtained by spinning were pre-carbonized in a muffle furnace (air atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com