Method for extracting trilobatin and phlorizin from lithocarpus litseifolius

A technology for trilobatin and phloridzin, which is applied in the field of extracting trilobatin and phloridizin, can solve the problems of large consumption of organic solvents, long extraction time, and many extraction times, and achieves increasing extraction amount, shortening extraction time, The effect of reducing the concentration of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The extraction of embodiment 1 sweet tea trilobatin and phlorizin of the present invention (small test)

[0032] Take wood ginger leaves Ke Nen leaves (sweet tea), dry at 50°C, grind at 17800rpm for 1min, pass through an 80-mesh sieve to obtain tea powder, seal it in a dry container, and store it at 4°C until use; The sample powder was put into a beaker and mixed with 20 mL ethanol aqueous solution (70%). After ultrasonic extraction at room temperature (25° C.) for 20 min, the supernatant was collected to obtain an extract. The ultrasonic power was 450 W.

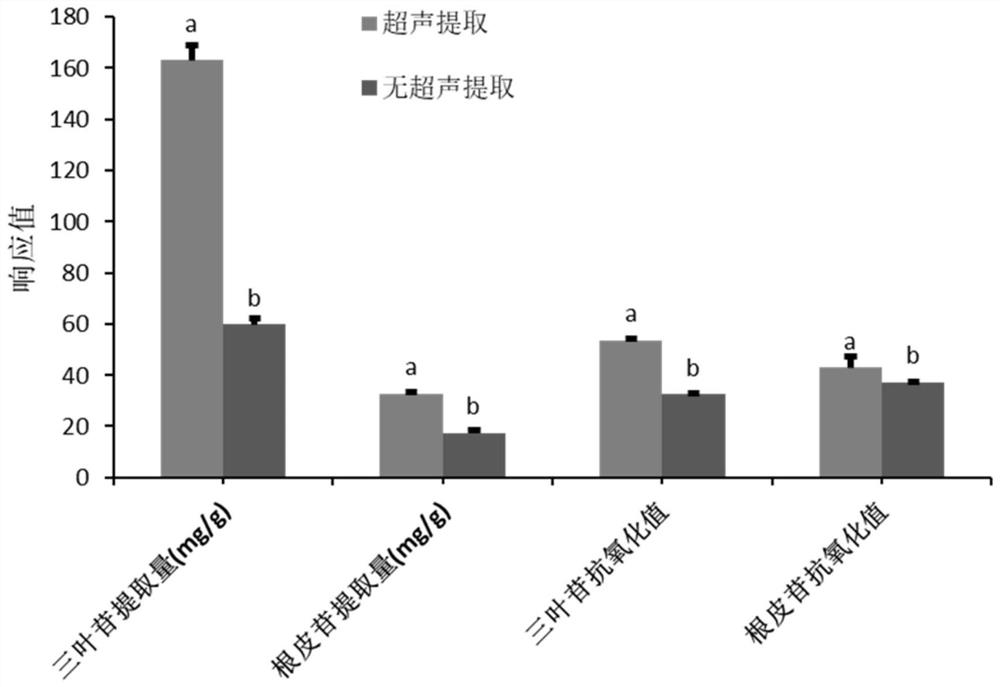

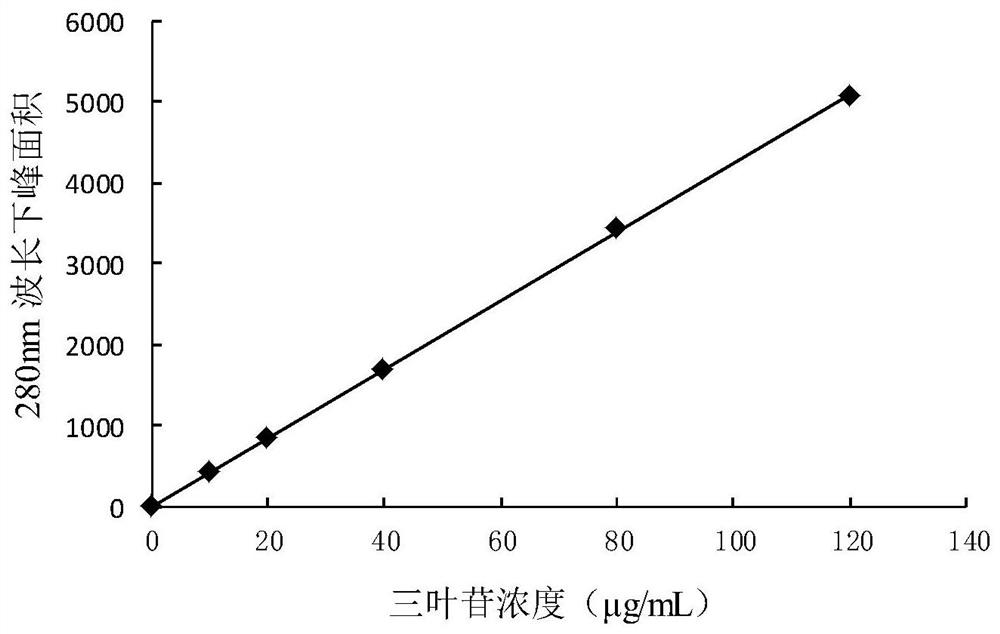

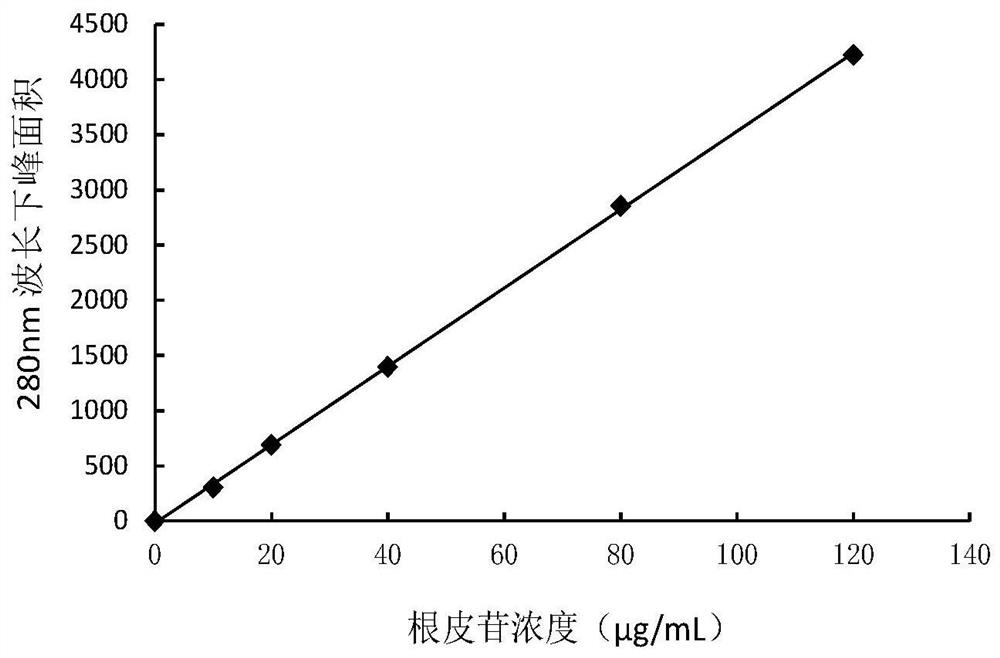

[0033] The obtained extract was diluted 200 times, and the obtained diluted sample was used to measure the contents of trilobatin and phlorizin in sweet tea by HPLC, and then the antioxidant activity was measured by DPPH-spiking method. Determination results: the contents of trilobatin and phlorizin were 162.93±9.321mg / g and 32.76±4.419mg / g respectively; the antioxidant values were 53.29±0.116%, 42.90±0.516%, respe...

Embodiment 2

[0034] The extraction of embodiment 2 sweet tea trilobatin and phlorizin of the present invention (small test)

[0035] Take wood ginger leaves Ke Nen leaves (sweet tea), dry at 50°C, grind at 17800rpm for 1min, pass through an 80-mesh sieve to obtain tea powder, seal it in a dry container, and store it at 4°C until use; The sample powder was put into a beaker and mixed with 20 mL ethanol aqueous solution (40%). After ultrasonic extraction at room temperature (25° C.) for 10 min, the supernatant was collected to obtain an extract. The ultrasonic power was 270 W.

[0036] The obtained extract was diluted 200 times, and the obtained diluted sample was used to measure the contents of trilobatin and phlorizin in sweet tea by HPLC, and then the antioxidant activity was measured by DPPH-spiking method. Determination results: the contents of trilobatin and phlorizin were 136.58±0.02mg / g and 29.31±0.03mg / g respectively.

Embodiment 3

[0037] Embodiment 3 The extraction of sweet tea trilobatin and phlorizin of the present invention (small test)

[0038] Take wood ginger leaves Ke Nen leaves (sweet tea), dry at 50°C, grind at 17800rpm for 1min, pass through an 80-mesh sieve to obtain tea powder, seal it in a dry container, and store it at 4°C until use; The sample powder was put into a beaker and mixed with 20 mL ethanol aqueous solution (70%). After ultrasonic extraction at room temperature (25° C.) for 30 min, the supernatant was collected to obtain an extract. The ultrasonic power was 450 W.

[0039] The obtained extract was diluted 200 times, and the obtained diluted sample was used to measure the contents of trilobatin and phlorizin in sweet tea by HPLC, and then the antioxidant activity was measured by DPPH-spiking method. Determination results: the contents of trilobatin and phlorizin were 142.51±0.15mg / g and 30.21±0.03mg / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com