A flexible automatic assembly line for oil cylinders

A production line and flexible technology, which is applied to the field of flexible automatic assembly production lines of oil cylinders, can solve the problems of unstable manual tightening torque of guide sleeves, difficult to guarantee the cleanliness of oil cylinder assembly, and high labor intensity of operation, so as to achieve the cleanliness of the cylinder body and the stable quality, The effect of low management cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

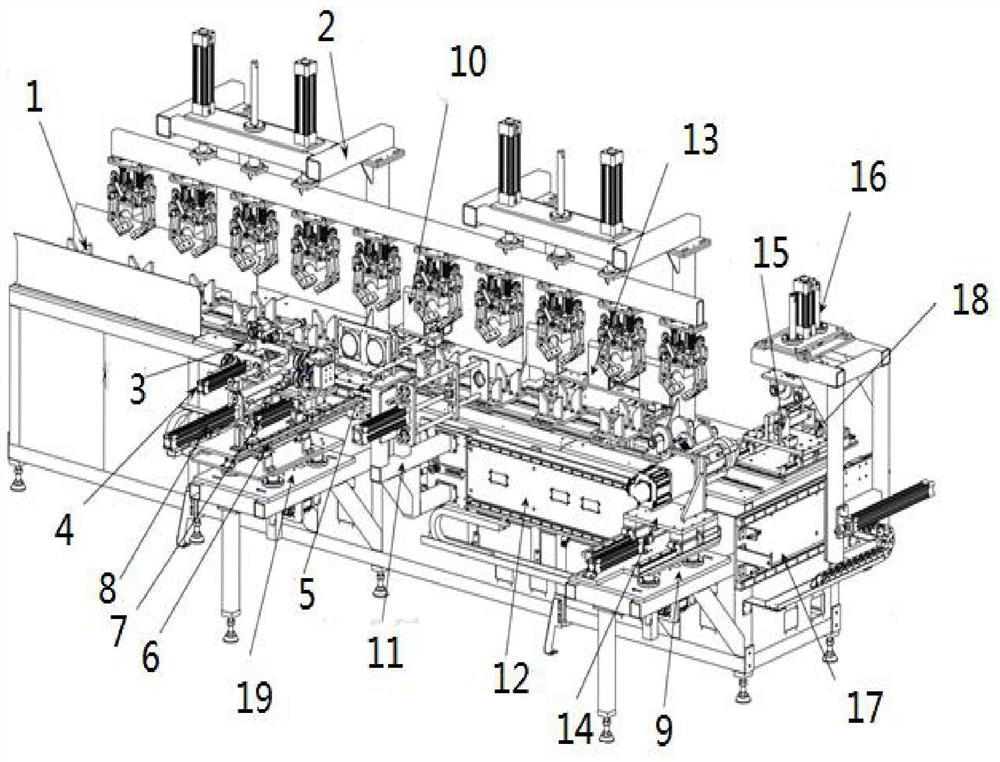

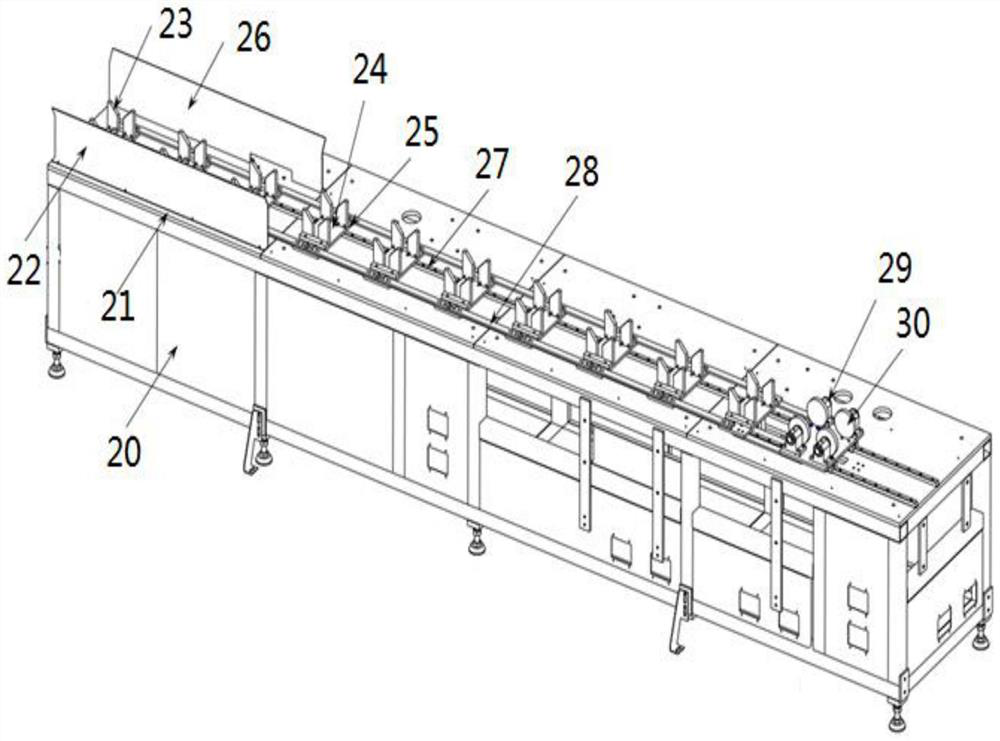

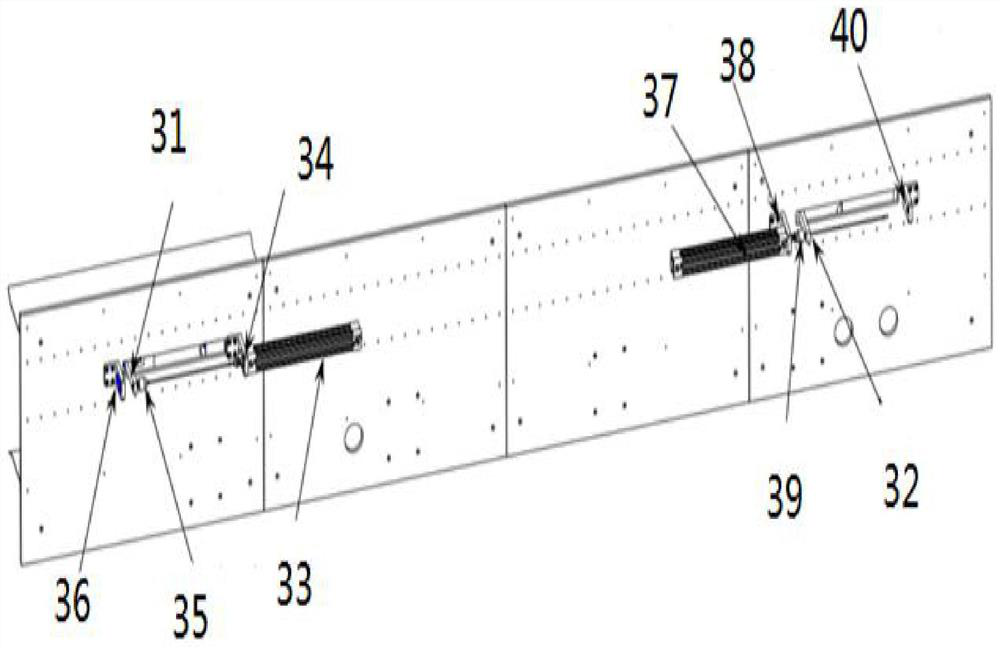

[0046] Such as Figure 1-20As shown, a flexible automatic assembly production line for oil cylinders includes a transfer mechanism 1, a lifting mechanism 2, an oil injection mechanism 3, a push rod mechanism 8, a guide mechanism 7, an upper sleeve mechanism 6, a sleeve changing mechanism 5, and a first servo jacking mechanism. Mechanism 9, first limit mechanism 10, auxiliary booster mechanism 11, first moving mechanism 12, second limit mechanism 13, guide sleeve tightening mechanism 14, second servo jacking mechanism 19, anti-rotation mechanism 15, pressing down Mechanism 16, anti-rotation adjustment mechanism 18, second moving mechanism 17, the transfer mechanism 1 enters the cylinder body from the left end of the production line, and outputs from the right end after passing through various structures in turn, and the transfer mechanism 1 tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com