A positioning platform for ultra-precise fast machining with large load

A positioning table, ultra-precision technology, applied in metal processing equipment, tool holders, manufacturing tools, etc., can solve problems such as difficulty in achieving high precision and micron-level dimensional processing, inability to achieve large load and rapid processing, and low stiffness in the direction of movement. , to achieve the effect of avoiding errors, convenient replacement and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

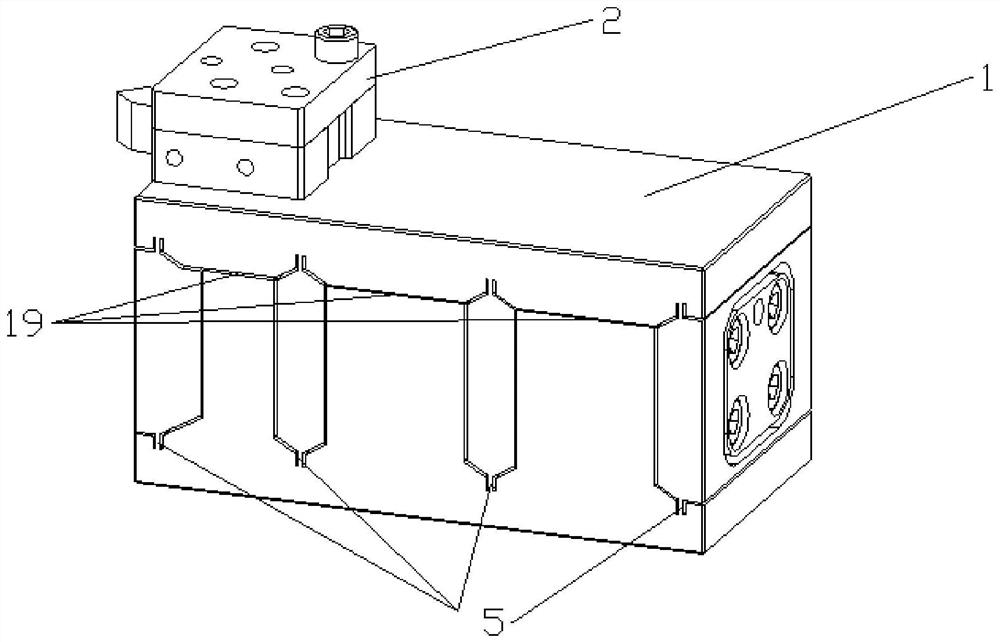

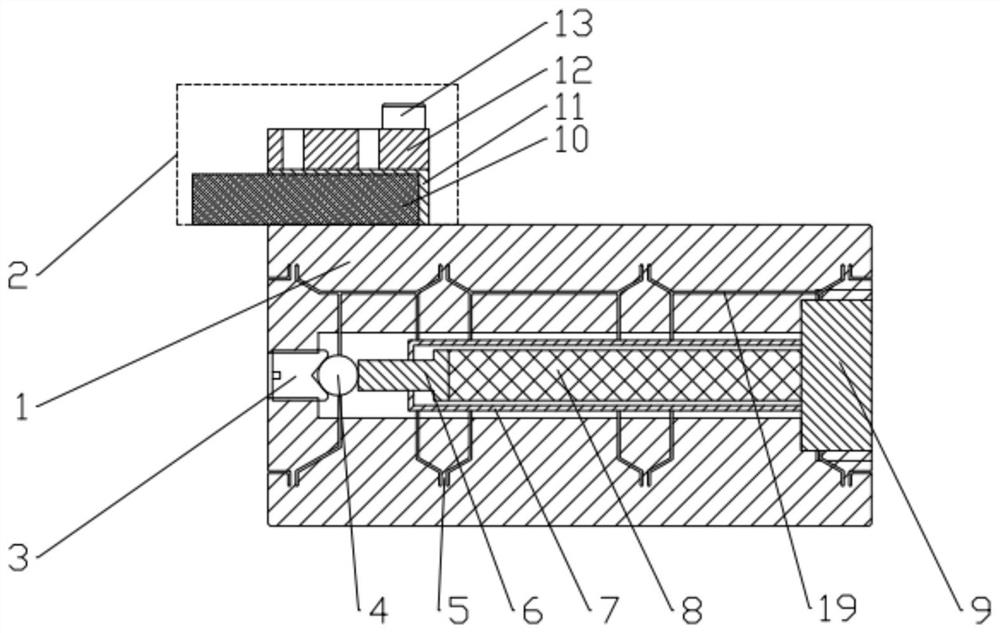

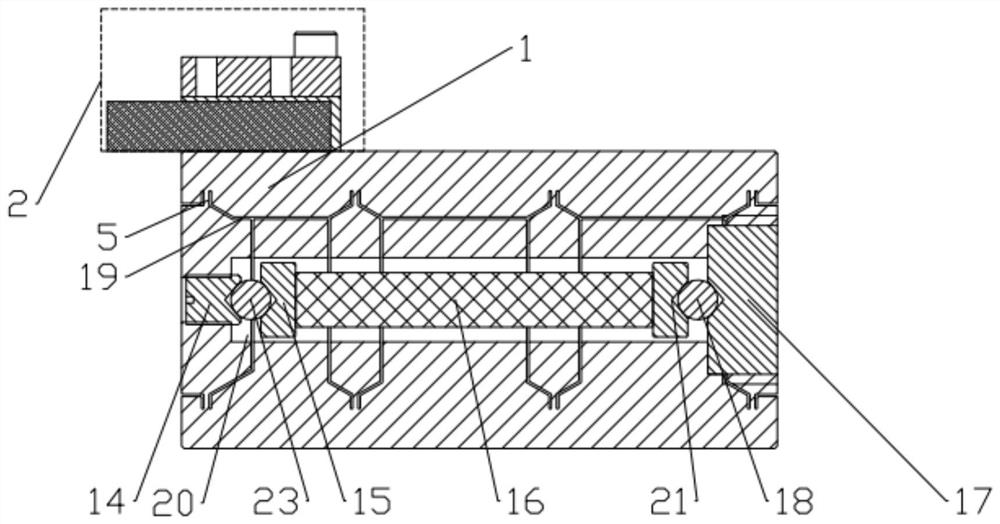

[0035] Such as Figure 1-Figure 5 As shown, a large-load ultra-precision rapid machining positioning table includes a fast-knife main table body 1 and a tool assembly 2, and the knife assembly 2 is installed on the upper left side of the fast-knife main table body 1. 1 is a cuboid structure, in the center of the main table body 1 of the fast knife, a stepped hole 20 in the middle of the table body is opened through the left and right end faces, and several flexible hinges 5 are formed by cutting the main table body 1 of the fast knife from the front end surface of the main table body 1 of the fast knife to the rear end surface. , cutting the flexible hinge 5 to form several cutting seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com