Novel core-shell structure catalyst for synergistic denitration and demercuration and preparation method ofnovel core-shell structure catalyst

A core-shell structure and catalyst technology, which is applied in the field of new core-shell structure catalysts and preparations for synergistic denitration and demercuration, can solve the problems of increasing the denitrification cost of enterprises, shortening the service life of catalysts, soil and groundwater pollution, etc., and achieving good low temperature Effects of denitrification activity, catalyst activity improvement, and excellent environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

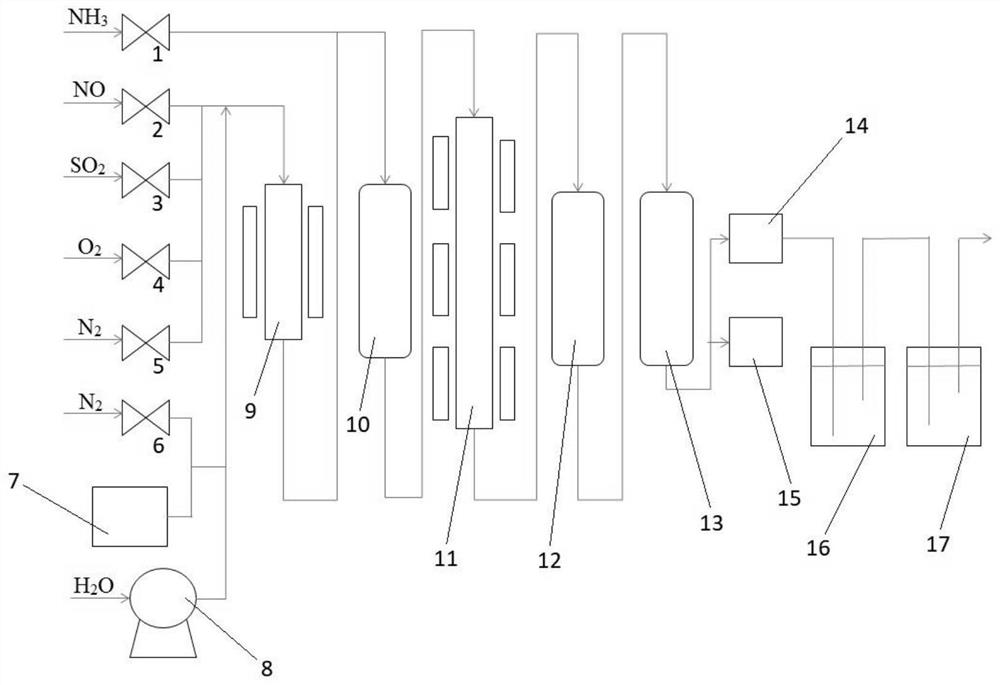

Image

Examples

Embodiment 1

[0049] This embodiment discloses the preparation method of the novel core-shell catalyst for synergistic denitration and demercuration of the present invention, specifically as follows:

[0050] Step 1. Preparation of α-MnO 2 nanorod particles

[0051] 72.70g of 50% potassium permanganate (KMnO 4 ) solution, 58.32g of manganese sulfate were added to 200mL of deionized water, then 2mL of concentrated sulfuric acid (98wt%) was added, and the above solution was stirred at room temperature until it was completely dissolved, then the solution was transferred to a polytetrafluoroethylene tank, and the polytetrafluoroethylene After the tetrafluoroethylene tank was sealed, it was placed in an oven at 80°C for constant temperature reaction for 12 hours. After the reaction is complete, the polytetrafluoroethylene tank is naturally cooled to room temperature, and the solid sediment in the tank is centrifuged and washed three times with deionized water and ethanol alternately until the ...

Embodiment 2

[0058] This example discloses the preparation method of the novel core-shell catalyst for synergistic denitration and demercuration of the present invention. Step 1 and step 2 of this embodiment are the same as in embodiment 1, only step 3 is different, specifically:

[0059] Step 1-2: same as embodiment 1;

[0060] Step 3. Preparation of CeO 2 -MnO 2 @TiO 2 Powder:

[0061] 319.05g of tetrabutyl titanate was dissolved in 478.58g of absolute ethanol, according to the titration rate of 10mL / min, 75g of 10% ammonia water was added to the mixed solution, and 52.63g of CeO 2 -MnO 2 Add the powder to the above solution, and stir at a constant speed of 300r / min throughout the process; transfer the suspension to a polytetrafluoroethylene tank, seal the polytetrafluoroethylene tank, and put it in an oven at 80°C for 12 hours of constant temperature reaction.

[0062] After the reaction is complete, naturally cool the polytetrafluoroethylene tank to room temperature, and centrifu...

Embodiment 3

[0064] This example discloses the preparation method of the novel core-shell catalyst for synergistic denitration and demercuration of the present invention. In this embodiment, step 1 and step 2 are the same as in embodiment 1, only step 3 is different, specifically:

[0065] Step 1-2: same as embodiment 1;

[0066] Step 3. Preparation of CeO 2 -MnO 2 @TiO 2 powder

[0067] Dissolve 425.4g of tetrabutyl titanate in 638.1g of absolute ethanol, add 100g of 10% ammonia water to the mixed solution according to the titration rate of 10mL / min, and dissolve 52.63g of CeO 2 -MnO 2 Add the powder to the above solution, and stir at a constant speed of 300r / min throughout the process; transfer the suspension to a polytetrafluoroethylene tank, seal the polytetrafluoroethylene tank, and put it in an oven at 80°C for 12 hours of constant temperature reaction.

[0068] After the reaction is complete, naturally cool the polytetrafluoroethylene tank to room temperature, and centrifugall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com