Automatic wall building machine and wall building method thereof

A wall-building machine and automatic technology, which is applied in construction, building construction, and building material processing, can solve problems such as difficulty in liberating labor force and failure to achieve mechanical automation, and achieve labor cost saving, strong applicability and operability , The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

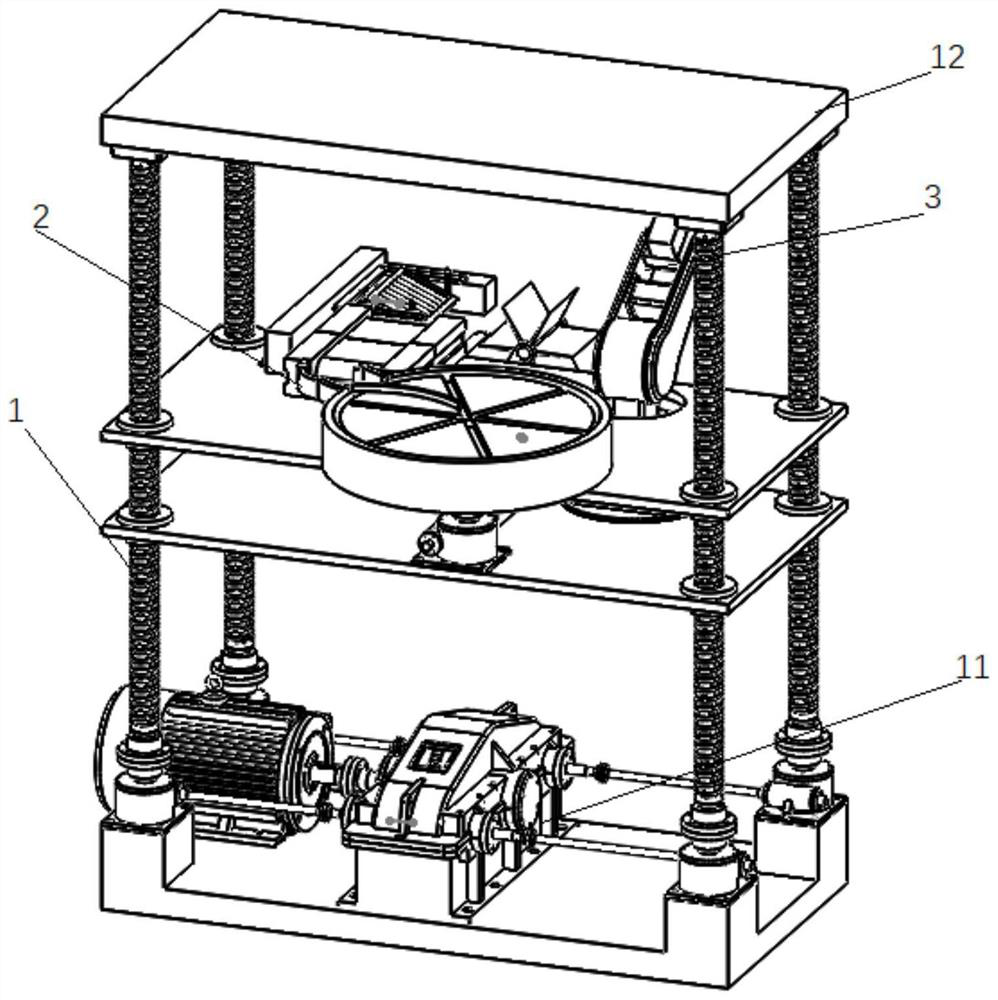

[0045] see figure 1 , an automatic wall-laying machine, comprising a lifting unit 1, a transport unit 2 and a cement spraying fixing unit 3.

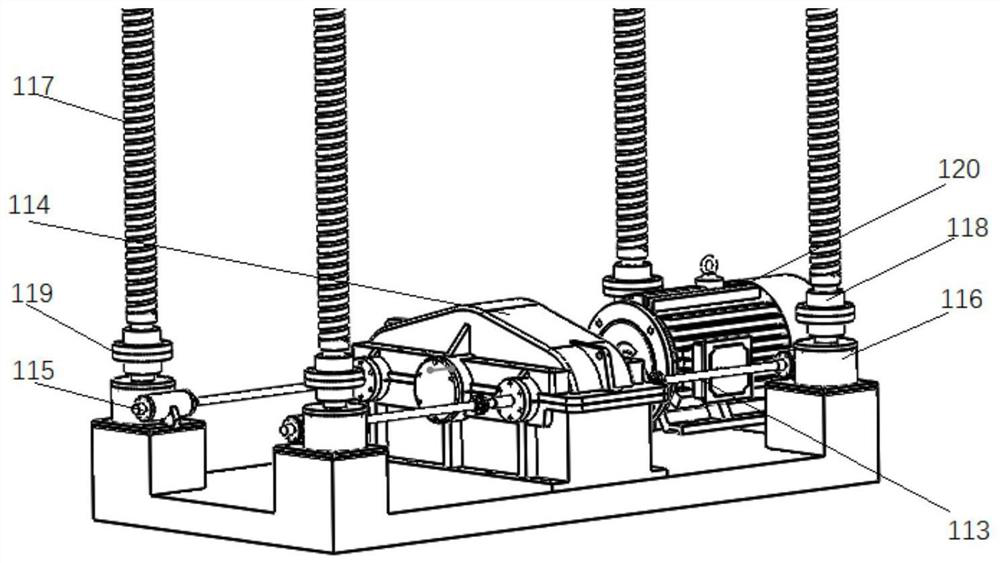

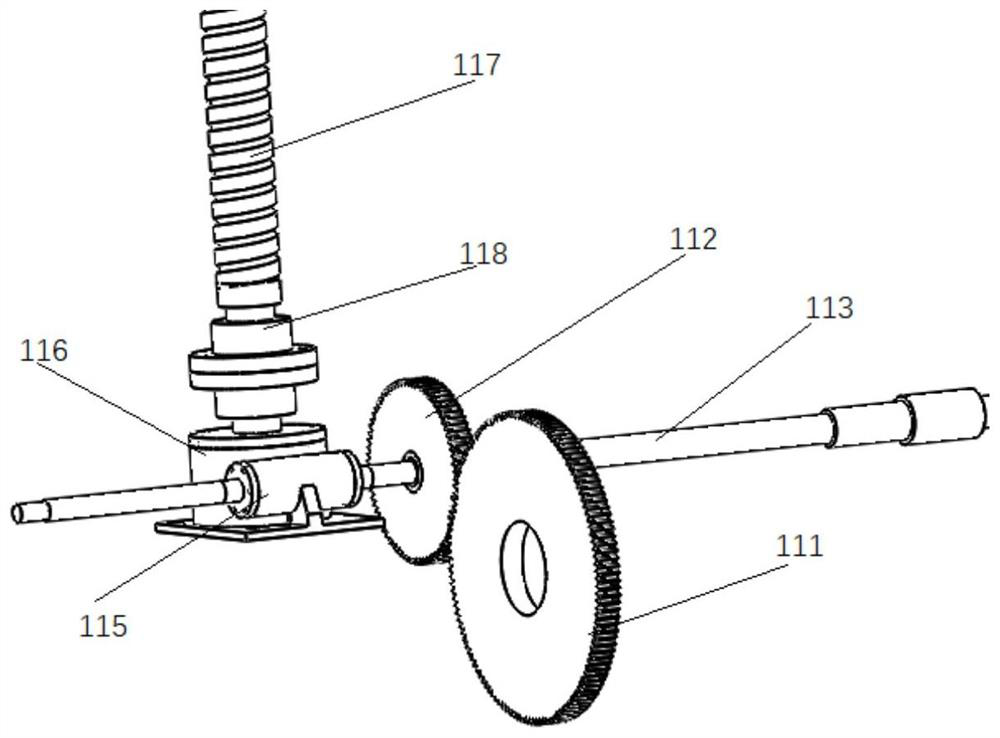

[0046] see figure 2 and image 3 , the lifting unit 1 includes a base 11 and a top structure 12, the base 11 includes a first transmission gear 111, a second transmission gear 112, a transmission shaft 113, a reducer case cover 114, a first worm 115, a first worm wheel 116, a wire Bar 117, nut 118, shaft coupling 119 and the first motor 120; Four leading screw 117 are all installed vertically; The transmission gear 111 is engaged, and the second transmission gear 112 is fixedly sleeved on one end of the first worm 115. The first worm 115 is engaged with the first worm wheel 116, and the first worm wheel 116 is connected with the lead screw 117 through a coupling 119, and a nut is used therebetween. 118 fixed. The first transmission gear 111 , the second transmission gear 112 , the transmission shaft 113 , and the reducer case cover...

Embodiment 2

[0050] Except the following content, all the other content are the same as embodiment 1.

[0051] see Figure 4 The top structure 12 of the lifting unit 1 includes a supporter 121 and a top working platform 122. One end of the lead screw 117 is connected with the worm wheel 116 through a coupling 119, and the other end of the lead screw 117 is fixed on the top working platform 122 by the supporter 121 through screws. inside. see Figure 7 , the lower end of the second worm wheel is fixed on the base, and is padded with a washer 210, and the upper end of the second worm wheel is connected with the rotating shaft 29 through a coupling.

Embodiment 3

[0053] Except the following content, all the other content are the same as embodiment 1.

[0054] see Figure 6 , the height of the fixed mount 25 can be adjusted, and the angle of the fixed mount 25 can also be adjusted. The fixed mount 25 is fixed by the support rod 241, and the support rod 241 can be adjusted for lifting and rotation, thereby realizing the adjustment of the fixed mount. When the bricks slide down from the load-bearing plate 23, they can be buffered to prevent the bricks from being damaged and reduce the performance of the product.

[0055] It should be noted that the combination of the first worm 115 and the first worm wheel 116 is fixed on the base 11 by screw connection, and a washer is placed in the middle to prevent the lubricating oil from leaking and polluting the atmosphere.

[0056] A wall-building method based on an automatic wall-building machine, comprising the steps of:

[0057] S1: Start the first motor 120, the first motor 120 drives the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com