Production process of high-purity gold

A production process and pure gold technology, which is applied in the field of high-purity gold production process, can solve the problems of long electrolysis production cycle, volatile extraction agent, and potential safety hazards, so as to shorten the gold melting process cycle, speed up the gold melting speed, and reduce the price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

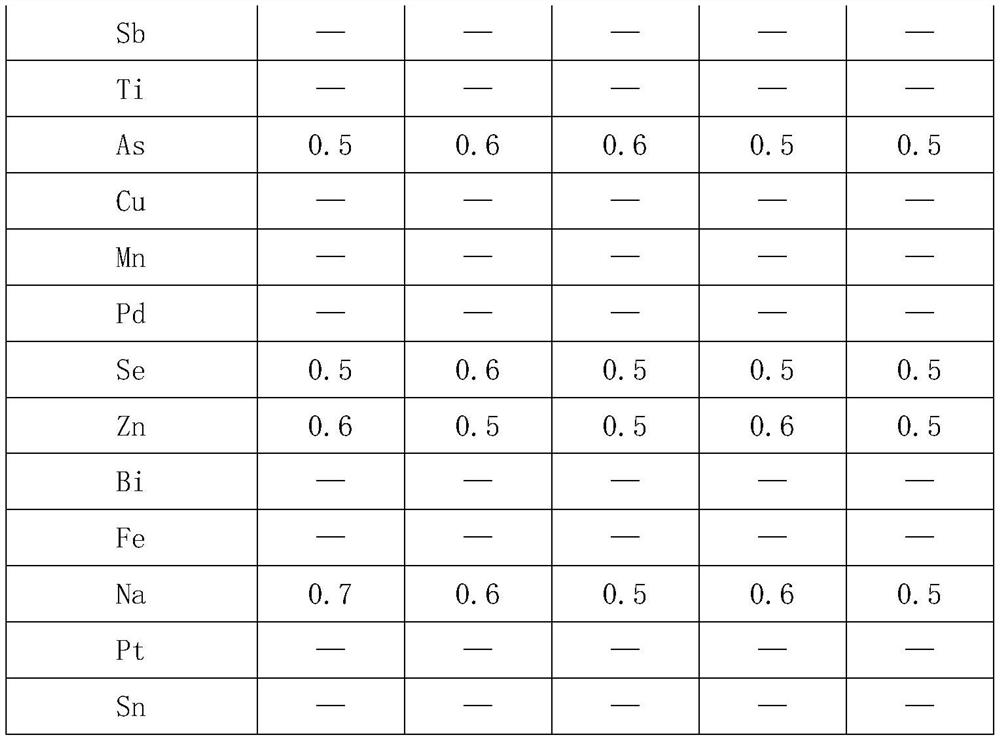

Image

Examples

Embodiment 1

[0041] Embodiment 1, a kind of production technique of high-purity gold, concrete production steps are as follows:

[0042]S1. Aqua regia soluble gold: put crude gold 1kg (gold content 99.000%) in the reactor, add 4L aqua regia in the reactor, aqua regia is the concentrated hydrochloric acid (mass fraction 37%) that volume ratio is 3:1 and concentrated Nitric acid (mass fraction 68%) is prepared. After the gold dissolving reaction is basically completed and the solution temperature drops to room temperature, add the nitration agent urea into the reactor at a uniform speed of 100g / min to catch the nitrate, and monitor the redox potential in the solution in real time. When the reduction potential E1 reaches 700mV, the dosing of urea is stopped, and the nitration rush is stopped, and the total amount of urea added during the nitration rush is 0.60kg. After the nitration process is stopped, the solution is filtered with a high-precision precision filter to obtain a crude gold sol...

Embodiment 2

[0046] Embodiment 2: A production process of high-purity gold. The difference between this embodiment and Embodiment 1 is that in step S1, when the oxidation-reduction potential E1 in the solution reaches 750mV, the dosing of urea is stopped, the nitration is stopped, and the nitration process is stopped. The total amount of urea added in the medium is 0.65kg. In step S2, the redox potential E2 is always controlled at 425mV, the dosage of reducing agent sodium sulfite is 0.65kg, and the reduction time t is 55min. In step S3, the number of times n of the fine gold powder being soaked in the nitric acid solution is 3 times, and the soaking time in nitric acid is 0.65 h each time.

Embodiment 3

[0047] Embodiment 3: A production process of high-purity gold. The difference between this embodiment and Embodiment 1 is that in step S1, when the oxidation-reduction potential E1 in the solution reaches 800mV, the dosing of urea is stopped, and the nitration process is stopped. The total amount of urea added was 0.70 kg. In step S2, the redox potential E2 is always controlled at 450mV, the total amount of reducing agent sodium sulfite added is 0.70kg, and the reduction time t is 60min. In step S3, the number of times n of the fine gold powder being soaked in the nitric acid solution is 4 times, and the soaking time in nitric acid is 0.75 h each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com