Moisture-curable modified polysiloxane and preparation method and application thereof

A technology of polysiloxane and moisture curing, which is applied in the field of silicone adhesives, can solve problems such as viscosity peaks, and achieve good bonding performance, low cost, and mild curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

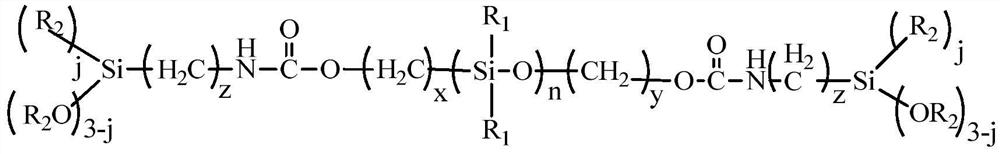

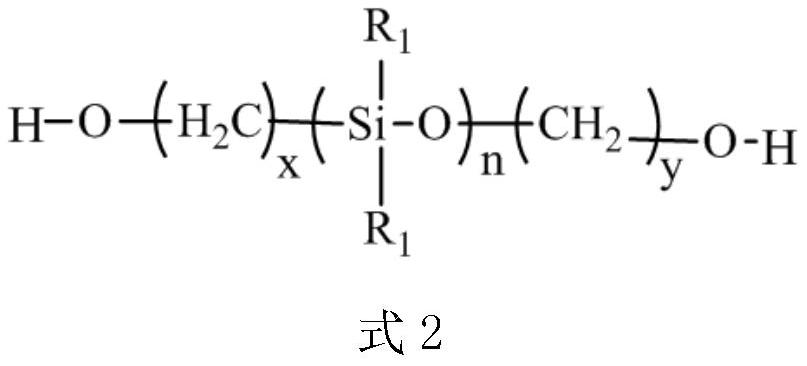

Method used

Image

Examples

Embodiment 1

[0050] Add 100g of hydroxyhydrocarbyl polysiloxane of 1000cst (hydroxyl content 6.0mmol / 100g), 1.3g of isocyanatopropyltrimethoxysilane, and n-titanate 1 part of butyl ester was stirred and reacted under vacuum for 4 hours to obtain a trimethoxy-terminated polysiloxane product with a viscosity of 1200 cst.

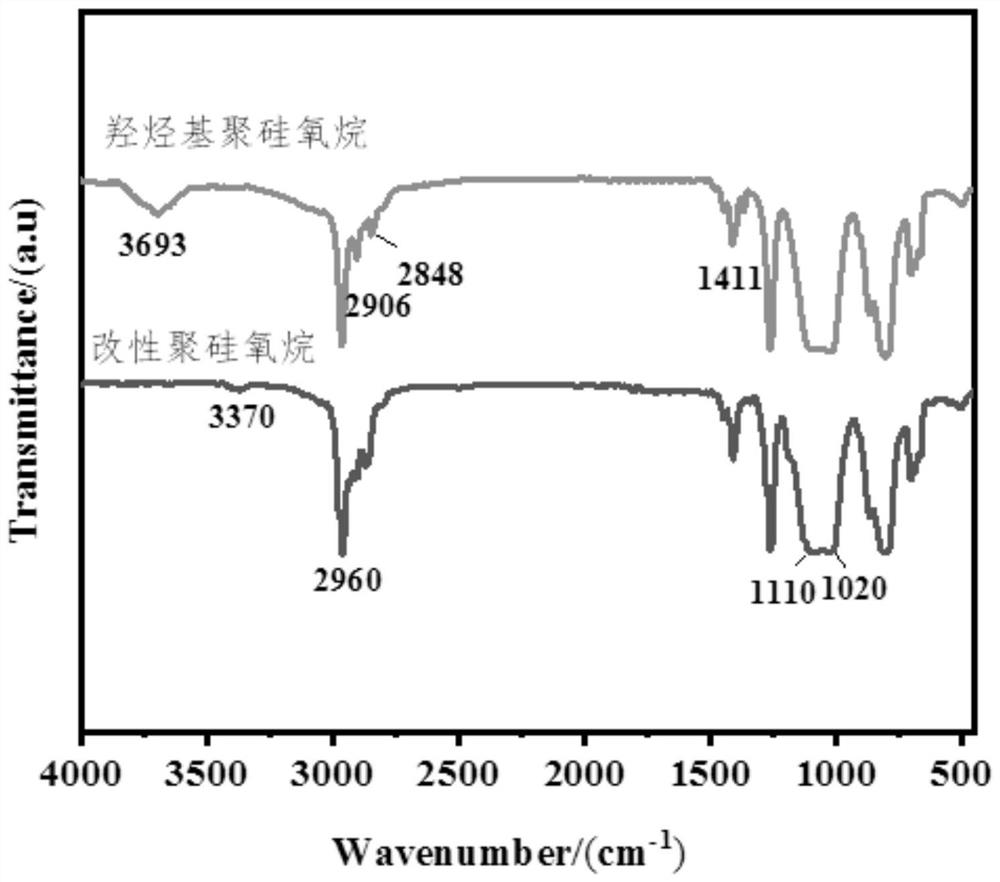

[0051] The IR comparison chart of hydroxyhydrocarbyl polysiloxane and trimethoxy end-capped polysiloxane product is as follows figure 1 . In hydroxyhydrocarbyl polysiloxane, silyl group (Si-CH 3 ) stretching vibration peak appears at 2 964cm -1 and 2 906cm -1 ; its symmetrical deformation vibration peak appears at 1261cm -1 and 1411cm -1 Office; 2848cm -1 The absorption at is attributed to the methylene (CH 2 ) characteristic peak; 1020cm -1 with 1 099cm -1 The characteristic absorption at is the antisymmetric stretching vibration absorption of the silicon-oxygen (Si-O-Si) bond, and the characteristic peak of the hydroxyl group (OH) appears at 3 693 cm -1 place. ...

Embodiment 2

[0053] Add 5000cst (hydroxyl content 3.0mmol / 100g) of hydroxyhydrocarbyl polysiloxane 100g, isocyanatopropyltriethoxysilane 0.9g, titanic acid 1 part of n-butyl ester was stirred and reacted under vacuum for 4 hours to obtain a triethoxy-terminated polysiloxane product with a viscosity of 6000 cst.

Embodiment 3

[0055] Add 20000cst (hydroxyl content 1.0mmol / 100g) of hydroxyhydrocarbyl polysiloxane 100g, isocyanatopropyl diethoxysilane 0.2g, titanic acid 1 part of n-butyl ester was stirred and reacted under vacuum for 4 hours to obtain dimethoxy-terminated polysiloxane with a viscosity of 23000 cst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com