Hot air heating, energy-saving and efficient small livestock and poultry manure composting equipment and method

A small-scale technology of livestock and poultry manure, which is applied in the field of small-scale livestock and poultry manure composting, can solve the problems of high energy consumption cost and slow fermentation rate, and achieve the effects of reducing energy consumption cost, prolonging the holding time, and increasing the fermentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

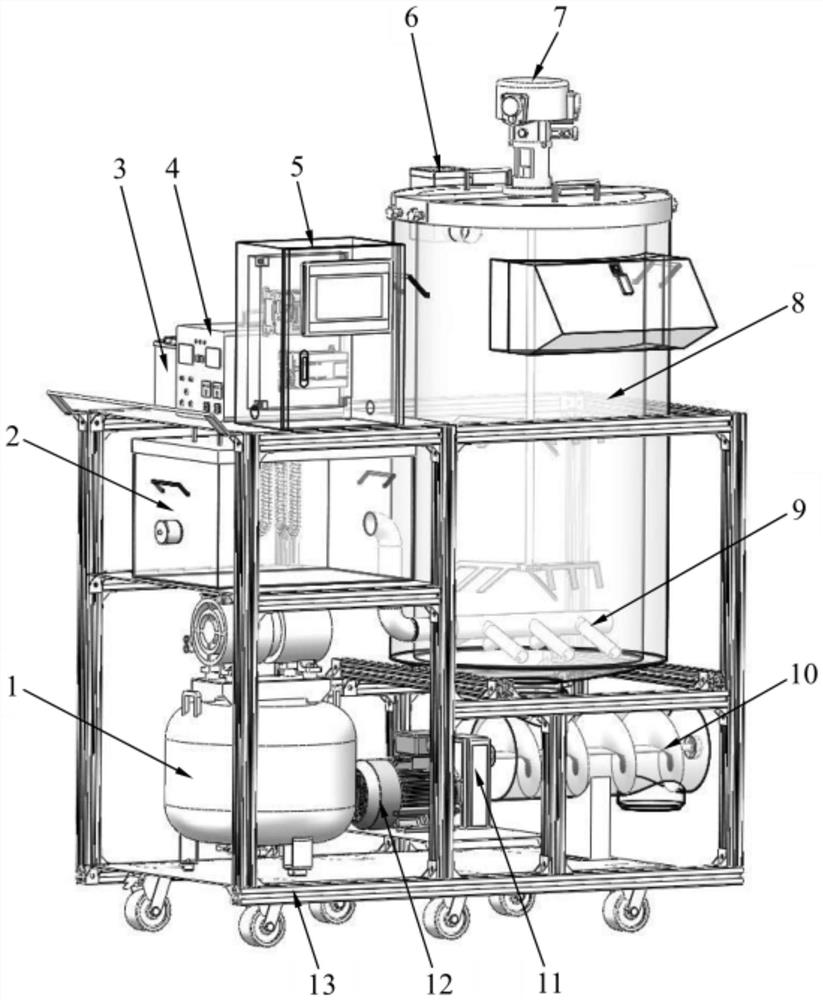

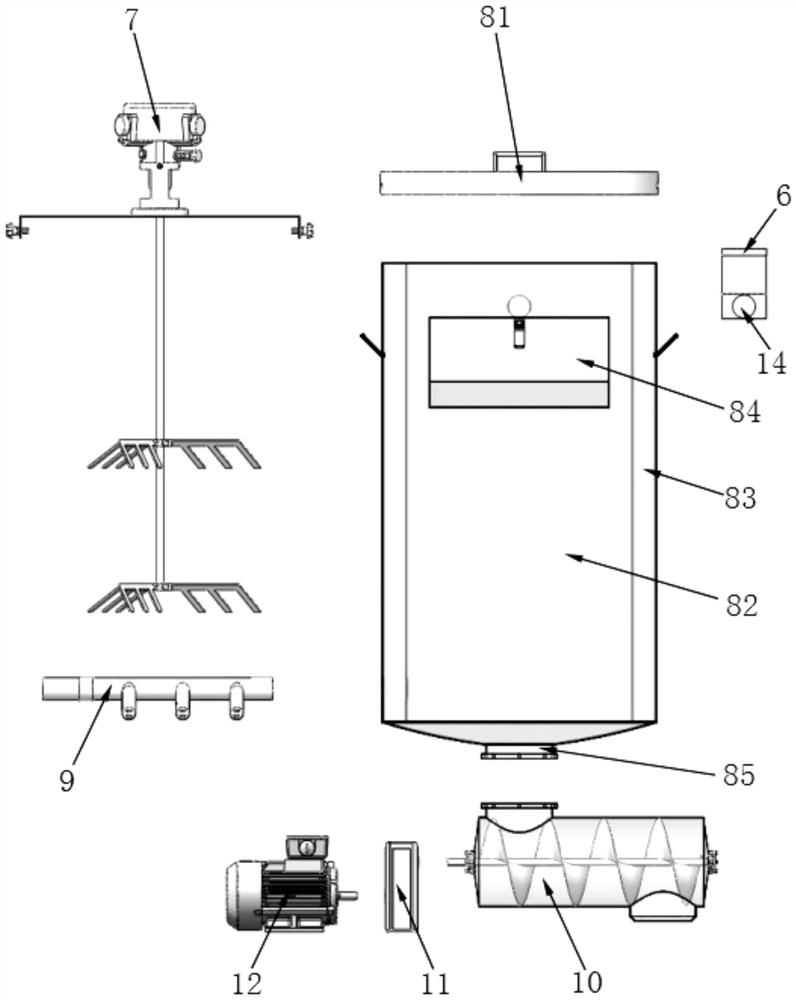

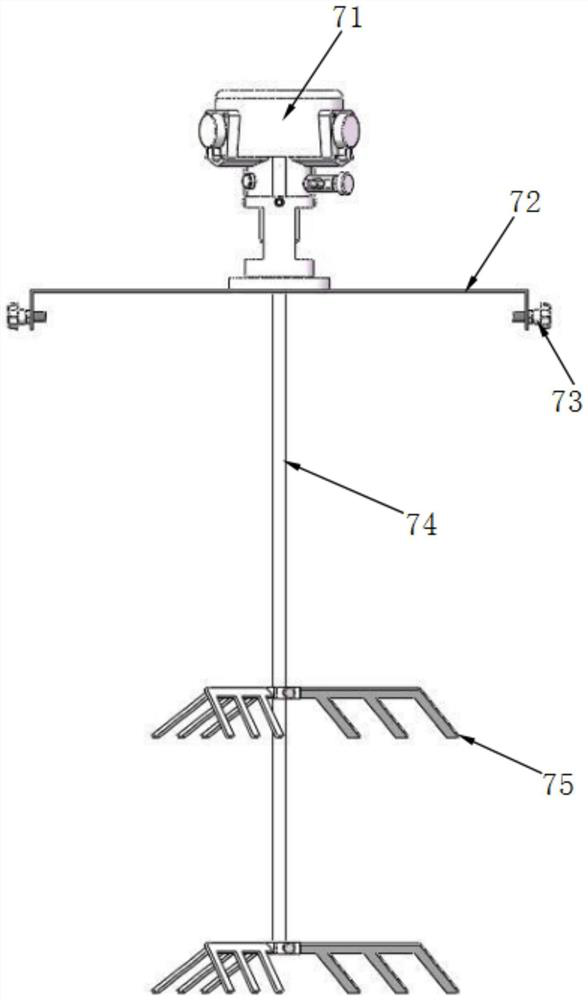

[0047] see Figure 1-6 , This embodiment provides a small-scale energy-saving and efficient composting equipment for livestock and poultry manure heated by hot air. In this embodiment, the equipment includes a frame 13, a stack fermentation system, an aeration and heating system, a control system and a power supply system.

[0048] The frame 13 includes a middle bottom plate 131 , a push handle 132 , an upper bottom plate 133 , a frame 134 , a plurality of right-angle fixing pieces 135 , a support piece 136 , a bottom bottom plate 137 , a support piece 2 138 and a plurality of universal wheels 139 . The middle base plate 131 is installed in the middle of the frame 134 , and the upper base plate 133 is installed in the upper portion of the frame 134 . The bottom bottom plate 137 is mounted on the bottom of the frame 134 and is used to support the pneumatic agitator 7 , support one 136 and support two 138 . Push handle 132 is installed on the frame 134, can be pushed and pulle...

Embodiment 2

[0070] This embodiment provides a small-scale livestock and poultry manure composting equipment heated by hot air and energy-saving and high-efficiency. On the basis of Embodiment 1, the control mode of the fermentation controller in the composting process is described. Wherein, the composting process of the compost includes a heating stage, a high temperature stage and a decomposing stage (also called a cooling stage). Among them, the high-temperature stage has the greatest impact on the composting degree of composting. The composting technology in this embodiment is a high-temperature aerobic composting technology, that is, during the composting process, the composting needs to be in contact with the air and the composting temperature needs to reach a certain range to effectively kill Pathogens and inactivation of plant seeds to improve compost maturity and organic fertilizer quality. Next, this embodiment introduces these three processes respectively.

[0071]In the heatin...

Embodiment 3

[0077] This embodiment provides a small-scale livestock and poultry manure composting method heated by hot air and energy-saving and high-efficiency. The composting method adopts an aeration heating mode or an aeration mode according to different situations, so as to adjust the composting temperature and the oxygen content of the fermentation bin. Wherein, the small-scale livestock and poultry manure composting method includes the following steps.

[0078] (1) Collect the temperature and humidity information of the stockpiles.

[0079] (2) Detect the oxygen content in the fermenter 8 .

[0080] (3) According to the temperature and humidity information and oxygen content, based on the preset heating mode and ventilation mode, the heating box 2 and the air pump 1 are controlled to realize the fermentation condition control of composting materials in different composting stages; wherein, the composting process of composting materials includes Heating stage, high temperature sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com