In-situ composite antibacterial filtering ceramic as well as preparation method and application thereof

A technology for in-situ composite and filtration of ceramics, applied in ceramic products, applications, filtration and separation, etc., can solve the problems of easy agglomeration of silver nanoparticles, loss of nanometer effect, etc., to avoid agglomeration, ensure filtration accuracy, and enhance binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

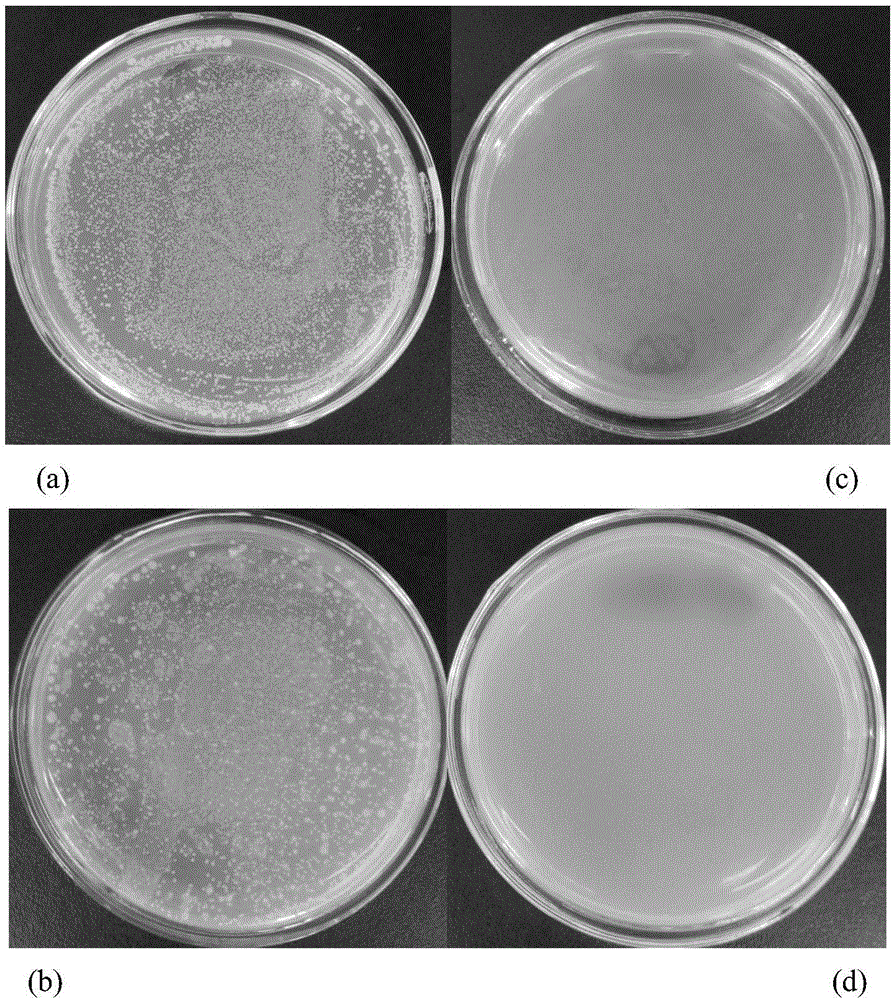

Examples

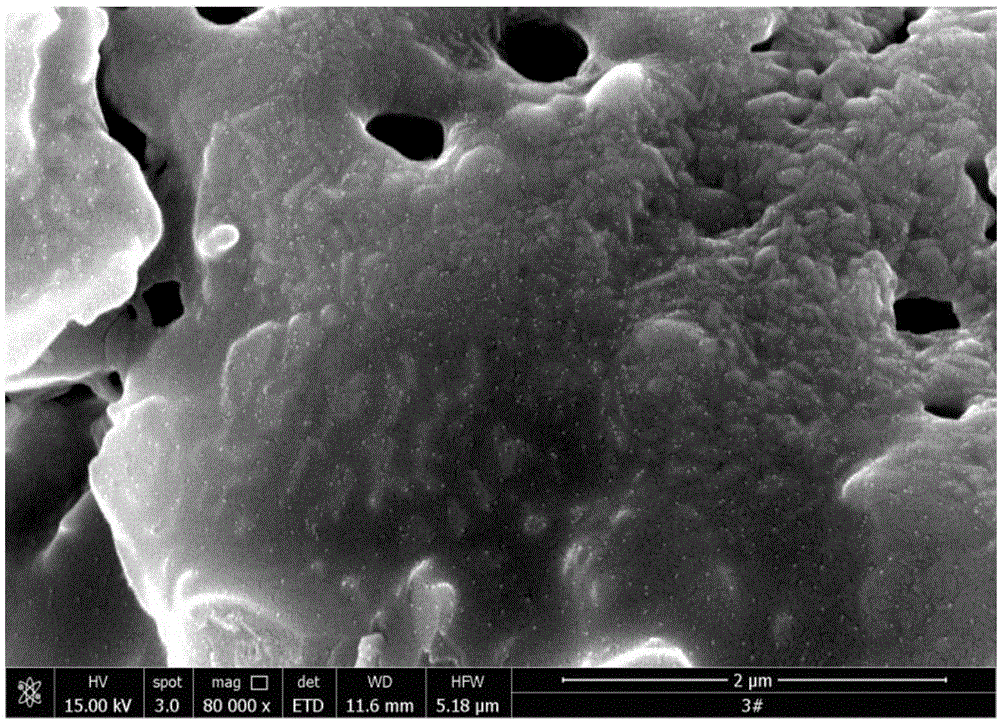

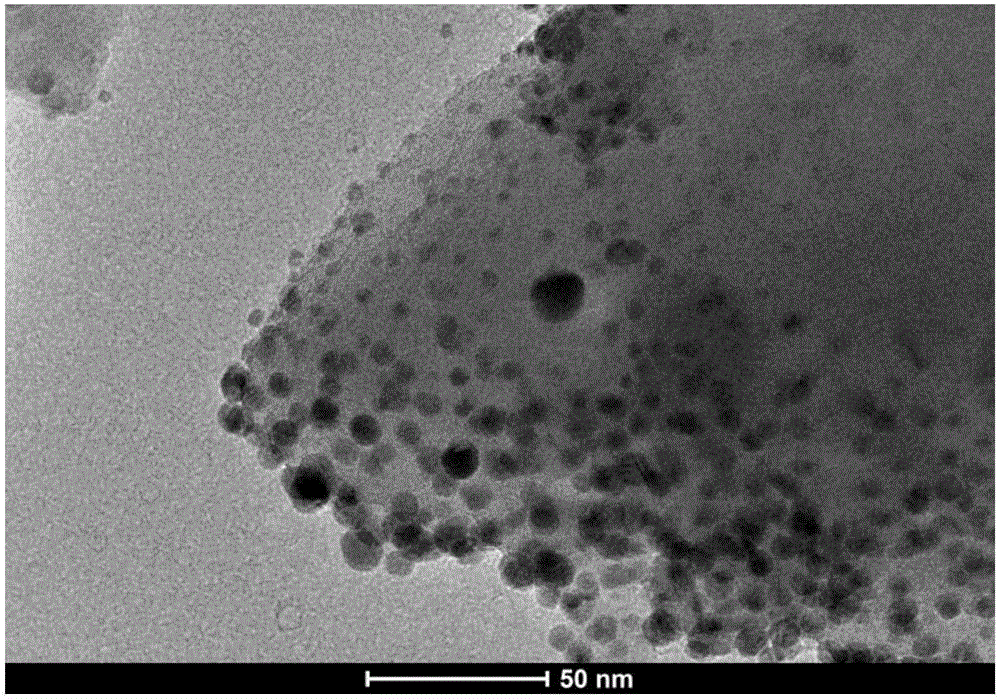

Embodiment 1

[0030] (1) Weigh 11.81gCa(NO 3 ) 2 ·4H 2 O, dissolve with 200mL deionized water to obtain 0.25mol / L calcium nitrate solution; weigh 3.96g (NH 4 ) 2 HPO 4 , dissolved in 100 mL of deionized water to obtain a 0.3 mol / L diammonium hydrogen phosphate solution, and adjusted its pH to 10 with ammonia;

[0031] (2) 0.3g AgNO 3 Add calcium nitrate solution to dissolve, and add 22.5g diatomite to obtain diatomite mixed solution;

[0032] (3) The diammonium hydrogen phosphate solution was added dropwise to the diatomite mixed solution and continuously stirred, then poured into the reaction kettle for hydrothermal reaction, the reaction temperature was 120°C, pH=10, and the reaction time was 4h;

[0033] (4) After the reaction solution obtained in step (3) was settled for 12 hours, the supernatant was poured out, washed with deionized water and ethanol, and filtered 3 times until the filtrate was basically neutral (pH=6~8), 70° C. drying to obtain dry powder;

[0034](5) Mix dry ...

Embodiment 2

[0044] (1) Weigh 11.1g CaCl 2 , dissolved in 300mL deionized water to obtain a 0.33mol / L calcium chloride solution; weigh 21.5gNa 2 HPO 4 ·12H 2 O, dissolve with 200mL deionized water to obtain a 0.3mol / L disodium hydrogen phosphate solution, and adjust its pH to 11 with ammonia water;

[0045] (2) 0.5gAgNO 3 Add to the calcium chloride solution to dissolve, and add 50g of diatomite to obtain a diatomite mixed solution;

[0046] (3) Add the disodium hydrogen phosphate solution dropwise into the mixed solution of diatomaceous earth and stir continuously, then pour it into the reaction kettle for hydrothermal reaction, the reaction temperature is 160°C, pH=11, and the reaction time is 6h;

[0047] (4) Precipitate the reaction solution obtained in step (3) for 12 hours, discard the supernatant, wash with deionized water and ethanol, and filter 3 times until the filtrate is basically neutral (pH=6-8). Dry to obtain dry powder;

[0048] (5) Batching dry powder and purple sand...

Embodiment 3

[0051] (1) Weigh 23.6g Ca (NO 3 ) 2 ·4H 2 O, dissolved in 200mL deionized water to obtain a 0.5mol / L calcium nitrate solution; weigh 12.18g (NH 4 ) 3 PO 4 , dissolved in 200mL deionized water to obtain a 0.3mol / L ammonium phosphate solution, and adjusted its pH to 11 with ammonia water;

[0052] (2) 0.9gAgNO 3 Add to dissolve in calcium nitrate solution, and add 35g diatomite, obtain diatomite mixed solution;

[0053] (3) Add the ammonium phosphate solution dropwise into the mixed solution of diatomaceous earth and stir continuously, then pour it into the reaction kettle for hydrothermal reaction, the reaction temperature is 160°C, pH=11, and the reaction time is 4h;

[0054] (4) Settling the reaction solution obtained in step (3) for 12 hours, discarding the supernatant, washing with deionized water and ethanol, and filtering 3 times until the filtrate is basically neutral (pH=6~8), at 80°C Dry to obtain dry powder;

[0055] (5) Mix dry powder and purple sand in a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com