Diamond tool cutting edge optimization method for edge burr removal

A diamond tool and burr removal technology, which is applied in the direction of manufacturing tools, metal processing equipment, turning equipment, etc., can solve the problems of poor process flexibility and adaptability, inability to eradicate burrs, and increased cost of deburring, so as to improve machining accuracy and motion stability, avoid excessive removal of burrs, and solve the effect of easy chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

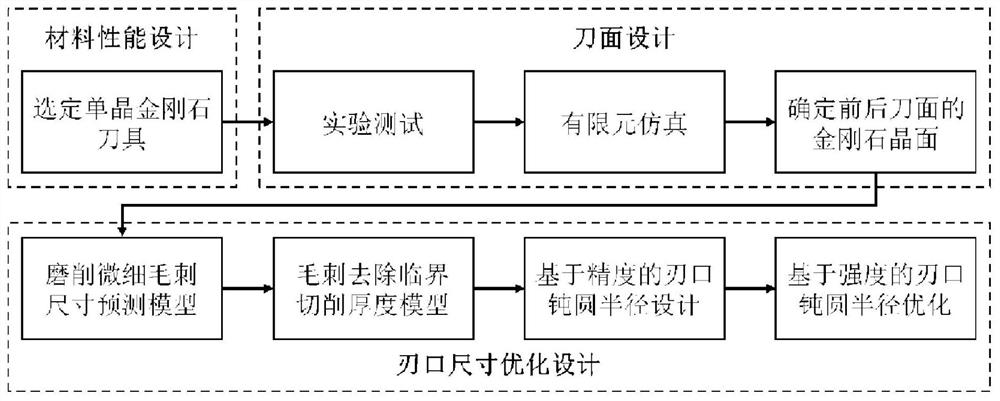

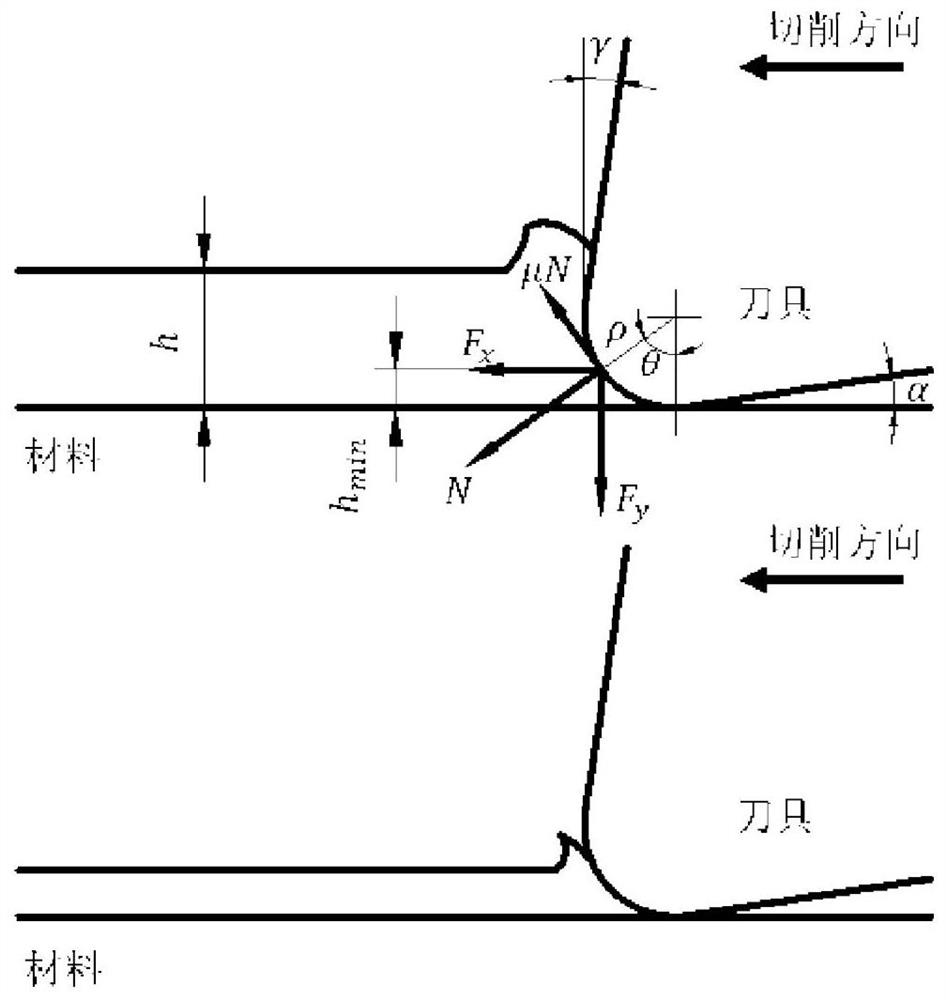

[0018] Such as figure 1 As shown, it is a diamond tool edge optimization implementation method for edge burr removal involved in this embodiment. A single crystal diamond tool is selected as the cutting edge material and the best crystal plane of the front and rear facets of the tool is determined, and the grinding of fine burrs is established. The size prediction model and the critical cutting thickness model for burr removal are used to calculate the design scheme of the blunt circle radius of the cutting edge based on accuracy and strength, so as to realize the optimization of the diamond tool cutting edge. The specific steps include:

[0019] Step 1: According to the micron-scale burr removal requirements on the edge and the actual production conditions, compare and test among superhard materials such as natural diamond, synthetic polycrystalline diamond and synthetic polycrystalline cubic boron nitride, and select single crystal diamond tools for deburring tool.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com