Protective coating of pipe wall, electroplating method and application

A coating and tube wall technology, which is applied to the protective coating of the tube wall and the electroplating method and application field, achieves the effects of being less prone to coating defects, reducing porosity and fully circulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides an electroplating method for a protective coating against sulfate-reducing bacteria corrosion. The coating is the inner coating of the oil pipe; the electroplating includes the method of flow electroplating, which is followed by rust removal, oil removal, pickling, neutralization and activation before the flow electroplating.

[0033] The specific process of the electroplating process in this embodiment is as follows:

[0034] High temperature degreasing→Inner wall derusting→Change tooling→Flowing degreasing→Flowing water washing→Flowing pickling→Flowing water washing→Flowing neutralization→Anode installation→Flowing water washing→Flowing activation→Flowing pure water washing→Semi-bright nickel plating→Flowing pure water washing → Bright copper electroplating → flowing pure water washing → highly dispersed bright nickel electroplating → flowing water washing → hanging → hydrogen removal treatment → packaging.

[0035] The main scheme and steps ...

Embodiment 2

[0048] With embodiment 1, the difference is that additives are added in the electroplating process, and the addition mode is that the first-stage additives are nickel sulfate 2.6kg / kAh, nickel carbonate 2.6kg / kAh, sodium lauryl sulfate 4g / kAh; the second-stage additives Copper sulfate 2.3kg / kAh, copper carbonate 2.1kg / kAh, polyethylene glycol 1.8g / kAh, sodium polydithiodipropane sulfonate 0.7g / kAh; the third stage additives are nickel sulfate 4.2kg / kAh, carbonic acid Nickel 2.2kg / kAh, sodium hypophosphite 80g / kAh, saccharin 23g / kAh, 1,4-butynediol 12g / kAh, coumarin 12g / kAh;

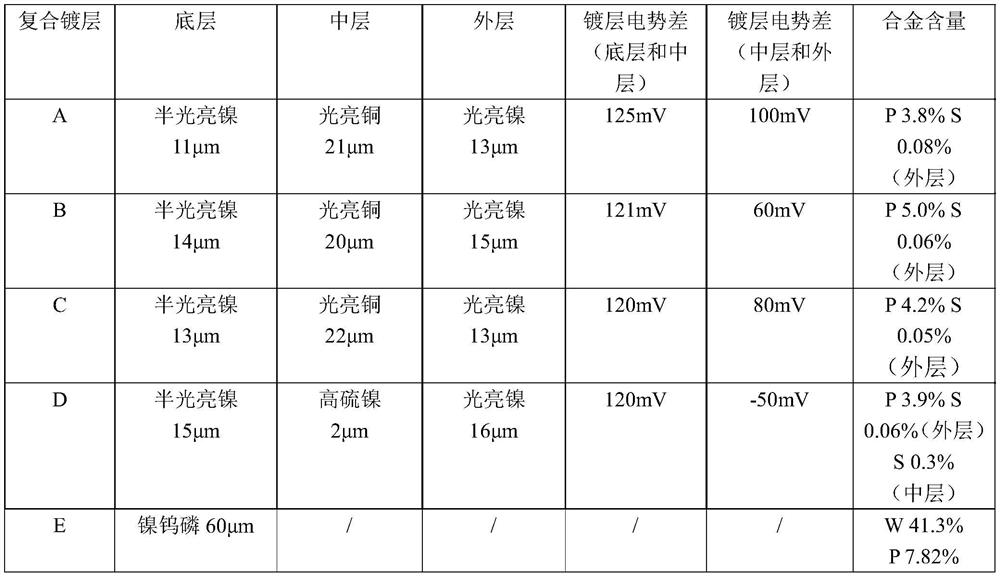

[0049] After adding 1 time, the resultant is composite coating B. The coating is uniform and the thickness error is 2%. The coating properties are shown in Table 1.

Embodiment 3

[0051] Same as Example 1, after adding 5 times according to the addition method of Example 2, the composite coating C was prepared. The coating is uniform and the thickness error is 3%. The coating properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com