Antibacterial, antiviral and deodorant cotton fiber and preparation method and application thereof

An antiviral and deodorizing cotton technology, applied in the field of cotton fiber, can solve the problems of poor bonding performance, affecting the durability of antibacterial function of cotton fiber, etc., and achieve the effect of improving stability, good antibacterial and antiviral performance, and avoiding damage or loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides the antibacterial, antiviral, deodorant cotton fiber preparation method described in above-mentioned technical solution, comprises the following steps:

[0046] Mix β-cyclodextrin, plant-based natural antibacterial agent, inorganic antibacterial agent and water first to obtain a β-cyclodextrin / antibacterial agent composite dispersion system;

[0047] The cotton fiber and the β-cyclodextrin / antibacterial compound dispersion system are mixed for the second time to obtain the adsorbed cotton fiber;

[0048] Performing stabilization treatment and irradiation treatment on the adsorbed cotton fibers in sequence to obtain antibacterial, antiviral and deodorant cotton fibers;

[0049] The solution for stabilization treatment is an aqueous solution of phytic acid.

[0050] In the invention, the beta-cyclodextrin, plant natural antibacterial agent, inorganic antibacterial agent and water are first mixed to obtain the beta-cyclodextrin / antibact...

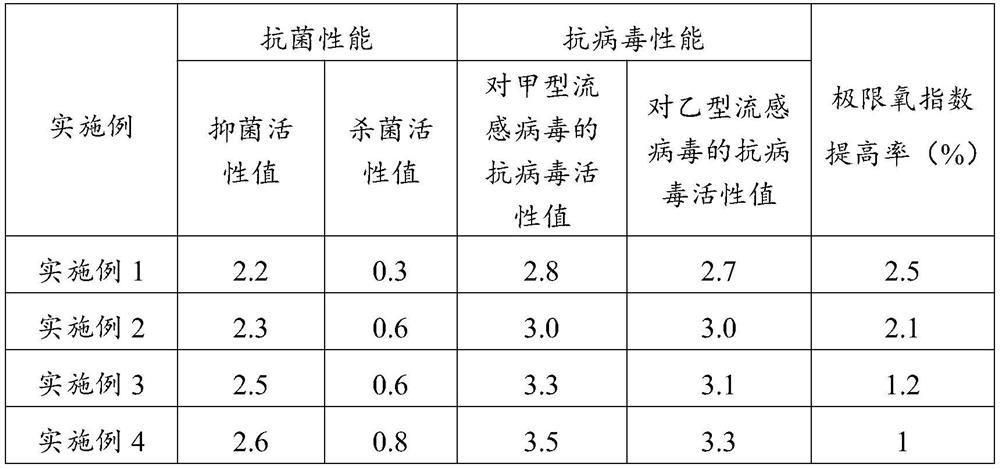

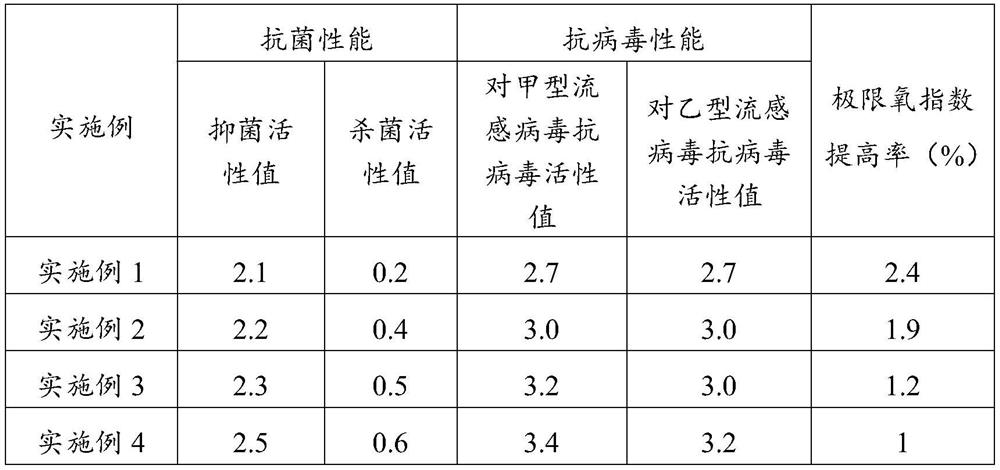

Embodiment 1

[0080] Immerse the carded cotton fibers in sodium hydroxide solution (200g / L, 20°C) for 80s, the bath ratio is 1:10, after pressing (the moisture content of cotton fibers after pressing is 60%), according to the water and cotton Washing (water, 20° C.) and pickling (20 g / L hydrochloric acid, 20° C.) at a fiber mass ratio of 15:1, so that the pH value of the mercerized cotton fiber is 8; After drying at ℃ for 50 minutes, perform plasma etching to obtain pretreated cotton fibers, wherein the working gas for plasma etching is air, the output power is 100W, and the time is 3 minutes;

[0081] Mix β-cyclodextrin with water (40°C) to obtain a saturated solution of β-cyclodextrin;

[0082] A saturated solution of β-cyclodextrin, plant natural extracts (tea extract, honeysuckle extract and Coptis chinensis extract with a mass ratio of 2:2:1) and ZnCl 2 Mixing, after stirring for 30min at a rotating speed of 1500r / min, stirring for 1.5h at a rotating speed of 500r / min to obtain a β-cy...

Embodiment 2

[0086] Immerse the carded cotton fibers in sodium hydroxide solution (225g / L, 23°C) for 68s, the bath ratio is 1:15, after pressing (the moisture content of cotton fibers after pressing is 75.2%), according to the water and cotton Fiber mass ratio is 21:1 consumption carries out water washing (water, 22 ℃), pickling (20g / L hydrochloric acid, 22 ℃), makes the pH value of the cotton fiber of mercerizing treatment be 7; The cotton fiber of mercerizing treatment is in After drying at 112°C for 41 minutes, perform plasma etching to obtain pretreated cotton fibers, wherein the working gas for plasma etching is air, the output power is 150W, and the time is 2.5 minutes;

[0087] Mix β-cyclodextrin with water (46°C) to obtain a saturated solution of β-cyclodextrin;

[0088] The saturated solution of β-cyclodextrin, plant natural extract (the mixture of tea leaf extract, Folium Isatidis extract, Radix Isatidis extract, the mass ratio of tea extract, Folium Folium Folium extract, Isatid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com