Immobilized carboxylesterase and preparation method and application thereof

A technology for immobilizing carboxylate and carboxylesterase, applied in the direction of immobilized enzymes, biochemical equipment and methods, enzymes, etc. Loading efficiency and other issues, to achieve good chemical and thermal stability, good reusability, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

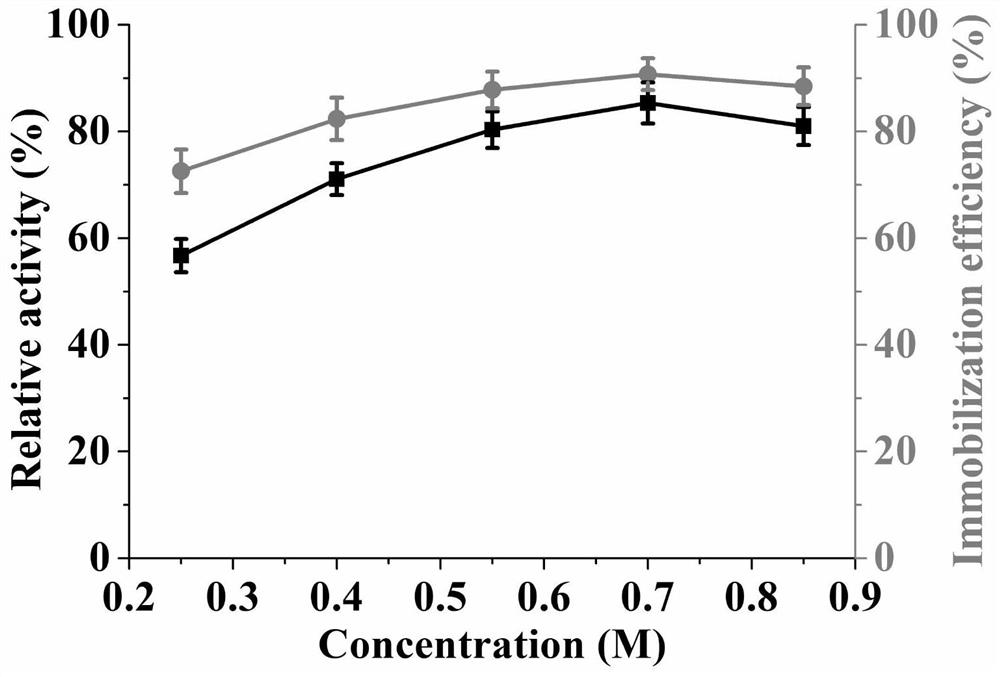

[0043] Example 1: Preparation of EstC@ZIF

[0044] Preparation of EstC protein solution: According to the steps of Example 1-4 in the patent application CN201910137250.2, EstC was expressed and purified.

[0045] Then, the purified protein solution was put into a Millipore ultrafiltration concentration tube (MW 10,000Da), centrifuged at 5,000 rpm for 30 min at 4°C, and the protein solution was concentrated to a concentration of 1.0 mg / mL.

[0046] Preparation of 2-methylimidazole solution: Weigh 2-methylimidazole and dissolve it in a certain volume of deionized water to prepare a 2-methylimidazole solution with a concentration of 2M.

[0047] Preparation of zinc acetate solution: Weigh zinc acetate and dissolve it in a certain volume of deionized water to prepare a zinc acetate solution with a concentration of 1M.

[0048] Add 3.5mL of the above-prepared 2-methylimidazole solution, 4.0mL of the concentrated EstC protein solution, and 2.1mL of deionized water into the Ep tube,...

Embodiment 2

[0059] Embodiment 2: the preparation of immobilized carboxylesterase

[0060] Add 4.25 mL of the 2-methylimidazole solution with a concentration of 2M prepared in Example 1, 3 mL of the concentrated EstC protein solution with a concentration of 1.0 mg / mL, and 2.55 mL of deionized water into the Ep tube together, and vortex Shake on the instrument for 30s, then add 0.2mL of the 1M zinc acetate solution prepared in Example 1, shake again for 30s, mix well, fix the Ep tube on a horizontal shaker, and react at 37°C for 30min, the reaction solution turns from clear to turbid , a large amount of precipitate was produced, and the precipitate was obtained by centrifugation at 6,000 rpm for 10 min. The precipitate was washed three times with ultrapure water and dried at 37°C to obtain the immobilized carboxylesterase.

Embodiment 3

[0061] Embodiment 3: the preparation of immobilized carboxylesterase

[0062] Add 2.75 mL of the 2-methylimidazole solution with a concentration of 2M prepared in Example 1, 4 mL of the concentrated EstC protein solution with a concentration of 1.0 mg / mL, and 3.05 mL of deionized water into the Ep tube together, and vortex Shake on the instrument for 30s, then add 0.2mL of the 1M zinc acetate solution prepared in Example 1, shake again for 30s, mix well, fix the Ep tube on a horizontal shaker, and react at 37°C for 30min, the reaction solution turns from clear to turbid , a large amount of precipitate was produced, and the precipitate was obtained by centrifugation at 6,000 rpm for 10 min. The precipitate was washed three times with ultrapure water and dried at 37°C to obtain the immobilized carboxylesterase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com