Five-spice vinegar and processing method thereof

A processing method and technology for five-spice vinegar, which are applied in the field of food brewing, can solve the problems of single formula of five-spice vinegar, and achieve the effects of promoting digestive juice secretion, good taste and soft sour taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

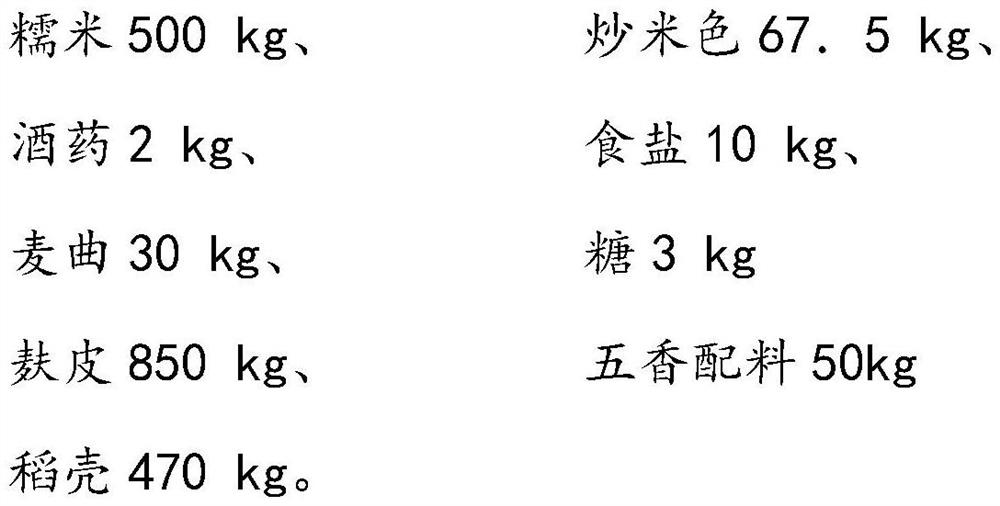

[0045] The invention provides spiced vinegar. The spiced vinegar is prepared from the following raw materials: glutinous rice, wine medicine, wheat koji, bran, rice husk, fried beige, salt, sugar and spiced ingredients. The weight ratio of each component is as follows:

[0046]

[0047] In this example, new-type balsamic vinegar is used to replace the aged vinegar in the raw material of spiced vinegar, so that the taste of spiced vinegar has been greatly improved. The balsamic vinegar has five characteristics of "color, aroma, acid, alcohol, and concentration", and its color is clear , soft sour taste, rich vinegar aroma, pure flavor, soft taste, fragrant and slightly sweet, strong color and delicious taste, and its quality remains unchanged for a long time, and it is more mellow. The biggest feature of balsamic vinegar is slightly sweet, especially dipped with When Jiangnan meat-filled snacks are eaten, the slightly sweetness can better reflect the deliciousness of the snac...

Embodiment 2

[0049] Preferably, the spiced vinegar spiced ingredients include the following ingredients:

[0050] a: Amomum 60g, cloves 12g, cardamom 7g, cinnamon 7g, sannai 12g;

[0051] b: Aniseed 20g dried ginger 5g cumin 8g pepper 18g tangerine peel 6g;

[0052] c: Aniseed 52g, cinnamon bark 7g, Sannai 10g, white pepper 3g, amomum 4g, dried ginger 17g, licorice 7g.

[0053] In the present embodiment, each formula corresponds to a kind of mouthfeel and efficacy, adopts different formulas, can produce the spiced vinegar of multiple different tastes, can cater to the taste of different regions, is convenient to carry out large-scale popularization and use, to the present invention long-term development has played a key role.

Embodiment 3

[0055]The invention provides a kind of spiced vinegar and processing method thereof, comprises the following steps:

[0056] (1) pretreatment of spiced vinegar;

[0057] (2) low-temperature saccharification of balsamic vinegar;

[0058] (3) acetic fermentation of balsamic vinegar;

[0059] (4) Balsamic vinegar aging stage;

[0060] (5) Get the vinegar unstrained spirits that aging of balsamic vinegar finishes and drench with vinegar;

[0061] (6) encapsulating and sterilizing the finished spiced vinegar.

[0062] The balsamic vinegar raw material processing in the pretreatment of step (1) spiced vinegar also includes the following steps:

[0063] a. Select high-quality rice and put it in the soaking tank and add clear water to soak for 15-24 hours. After soaking, the rice grains are required to be soaked without white heart;

[0064] b. Remove and drain, steam the drained glutinous rice, and then cool it down to 25°C in summer and 30°C in winter;

[0065] c. Stir in 2kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com