Antibacterial spraying-free material capable of efficiently releasing negative ions and preparation method thereof

A negative ion antibacterial and spray-free technology, which is applied in the field of high-efficiency negative ion antibacterial antibacterial spray-free materials and its preparation, can solve the problems of affecting the amount of negative ion release and easy agglomeration, so as to achieve excellent antibacterial effect, improve antibacterial effect, and increase the release of negative ions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

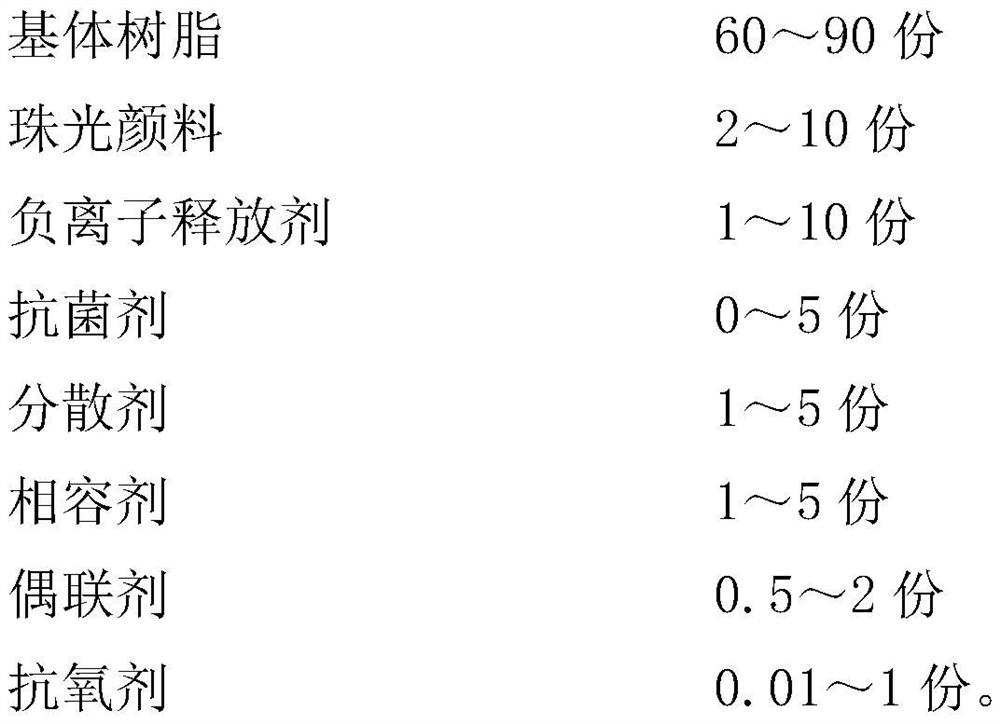

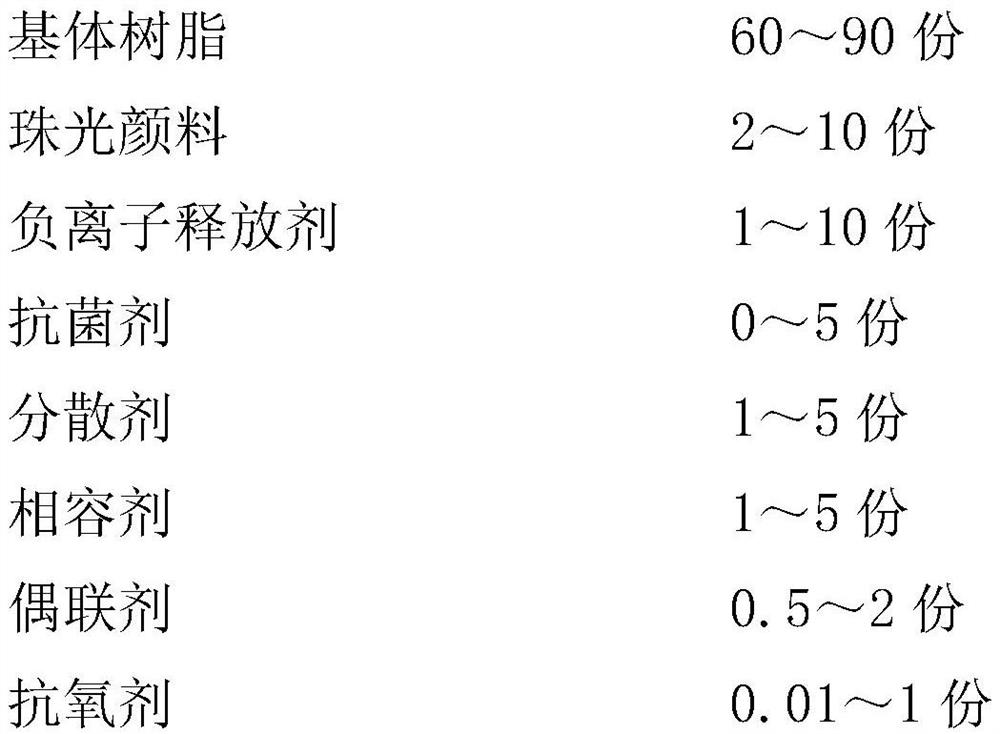

Method used

Image

Examples

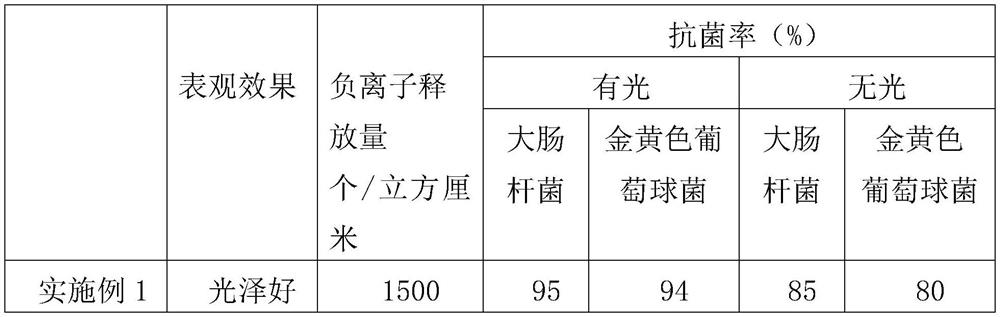

Embodiment 1

[0036] The preparation of a kind of high-efficiency negative ion antibacterial spray-free material comprises the following steps:

[0037](1) Preparation of negative ion releasing agent: Take 300 mL of distilled water and add 5 g of tourmaline powder in a three-necked cup, stir in a cold water bath for 2 min, take 1 mL of 1.0 mol / L titanium tetrachloride stock solution, and drip it into the mixed solution with a constant flow pump; The prepared 1mol / L ammonium sulfate solution 5mL and hydrochloric acid 3mL were mixed and added dropwise to the reaction system, after mixing and stirring for 10min, the temperature was raised to 50°C and kept for 0.5h; 3 ·H 2 O / VH 2 O=1:2 to adjust the pH value of the mixed solution to 4. After 1 hour of reaction, the reaction solution was filtered and dried, dried at 80°C, calcined at 500°C for 5 hours, and cooled to room temperature to prepare an anion release agent with a particle size of 100-300nm .

[0038] (2) Prepare the raw materials of...

Embodiment 2

[0043] The preparation of a kind of high-efficiency negative ion antibacterial spray-free material comprises the following steps:

[0044] (1) Preparation of negative ion releasing agent: Take 300ml of distilled water and add 20g of tourmaline powder in a three-necked cup, stir in a cold water bath for 10min, take 1mL of 5.0mol / L titanium tetrachloride stock solution, and drip it into the mixed solution with a constant flow pump; Mix 5mL of the prepared 5mol / L ammonium sulfate solution and 3ml of hydrochloric acid and add it dropwise to the reaction system. After mixing and stirring for 10min, raise the temperature to 100°C and keep it warm for 1h; use VNH 3 ·H 2 O / VH 2 O=1:5 to adjust the pH value of the mixture to 7. After 2 hours of reaction, the reaction solution was filtered and dried, dried at 150°C, calcined at 900°C for 1 hour, and cooled to room temperature to prepare an anion release agent with a particle size of 100-300nm. .

[0045] (2) Prepare the raw materials...

Embodiment 3

[0050] The preparation of a kind of high-efficiency negative ion antibacterial spray-free material comprises the following steps:

[0051] (1) Preparation of negative ion releasing agent: take 300ml of distilled water and add 15g of tourmaline powder in a three-necked cup, stir in a cold water bath for 6min, take 1mL of 2.0mol / L titanium tetrachloride stock solution, and drip it into the mixed solution with a constant flow pump; Mix 5mL of the prepared 3mol / L ammonium sulfate solution and 3ml of hydrochloric acid and add it dropwise to the reaction system. After mixing and stirring for 10min, raise the temperature to 70°C and keep it warm for 1h; use VNH 3 ·H 2 O / VH 2 O=1:3 to adjust the pH value of the mixture to 4.5. After 2 hours of reaction, the reaction solution was filtered and dried, dried at 103°C, calcined at 550°C for 2 hours, and cooled to room temperature to prepare an anion release agent with a particle size of 100-300nm. .

[0052] (2) Prepare the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com