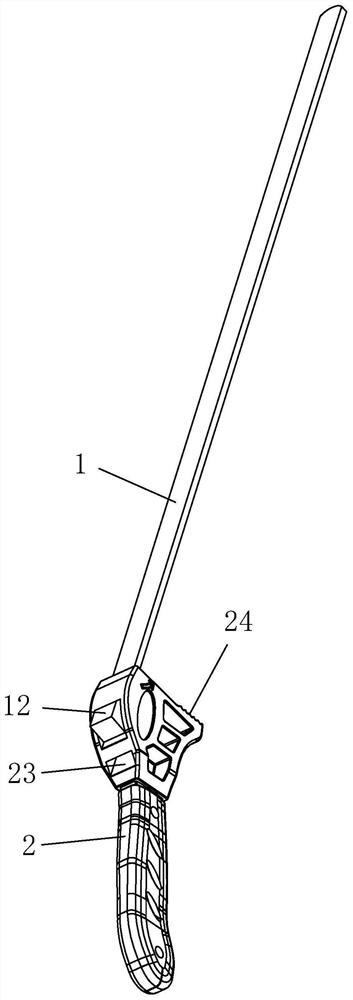

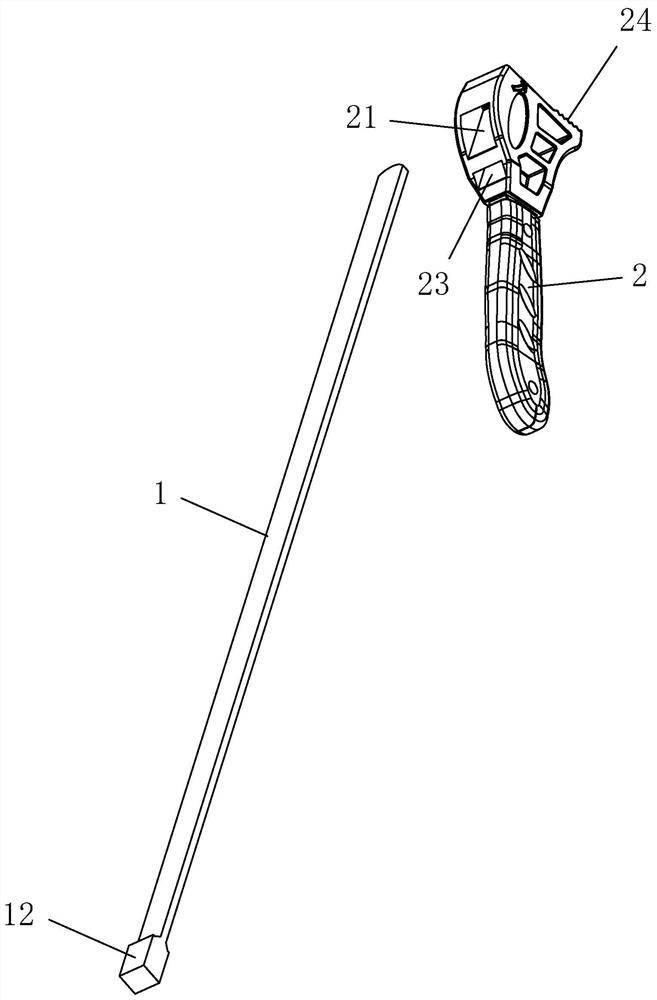

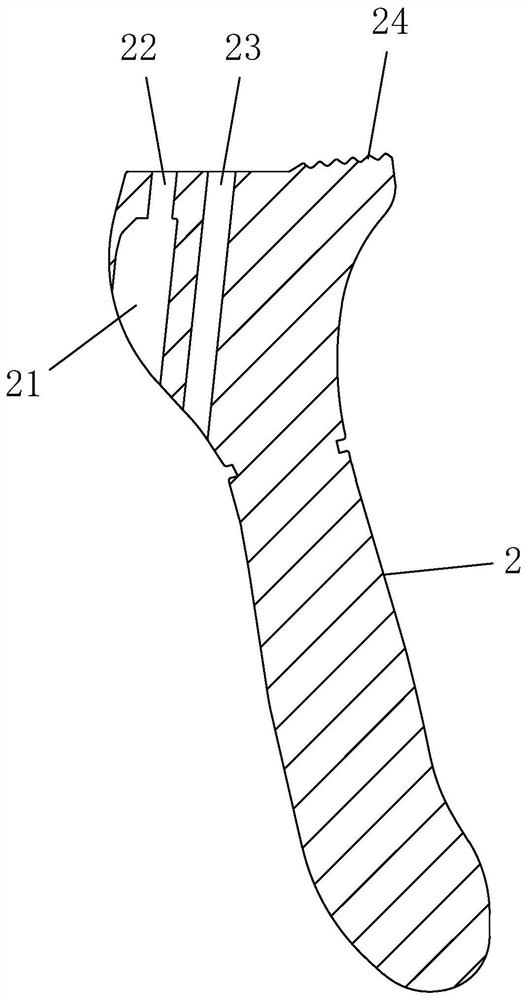

Rubber belt wrench and manufacturing method of rubber belt thereof

A manufacturing method and technology of rubber belts, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of softness, temperature resistance, poor chemical resistance, complex processing technology of hardware wrenches, high failure rate, etc., and achieve good oil resistance , low scalability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0110] Below in conjunction with embodiment 1-3 the present invention is described in further detail:

Embodiment 1

[0112] Manufacture the rubber belt 1 according to the following method, wherein the number of tendon threads is 8, and the specific steps are as follows:

[0113] Step S1: Weigh and obtain the required raw materials of each component according to the following parts by mass:

[0114] 100 parts of nitrile rubber;

[0115] 5.0 parts of zinc oxide;

[0116] 1.0 parts of stearic acid;

[0117] Antiaging agent 4010 1.5 parts;

[0118] Carbon black N550 40 parts;

[0119] Carbon black N774 27 parts;

[0120] 30 parts of environmentally friendly plasticizers;

[0121] 40 parts of calcium carbonate;

[0122] Sulfur 1.9 parts;

[0123] 2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide;

[0124] 0.87 parts of tetramethylthiuram disulfide;

[0125] Step S2: Put the nitrile rubber into the internal mixing chamber of the internal mixer and masticate for 80s±10s, and masticate the nitrile rubber from block to powder;

[0126] Step S3: Add zinc oxide, stearic acid and antioxidant...

Embodiment 2

[0136] Manufacture the rubber belt 1 according to the following method, wherein the number of tendon threads is 8, and the specific steps are as follows:

[0137] Step S1: Weigh and obtain the required raw materials of each component according to the following parts by mass:

[0138] 100 parts of nitrile rubber;

[0139] 5.0 parts of zinc oxide;

[0140] 1.0 parts of stearic acid;

[0141] Antiaging agent 4010 1.5 parts;

[0142] Carbon black N550 40 parts;

[0143] Carbon black N774 27 parts;

[0144] Environmental protection plasticizer 25 parts;

[0145] 30 parts of calcium carbonate;

[0146] Sulfur 1.9 parts;

[0147] 2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide;

[0148] 0.87 parts of tetramethylthiuram disulfide;

[0149] Step S2: Put the nitrile rubber into the internal mixing chamber of the internal mixer and masticate for 80s±10s, and masticate the nitrile rubber from block to powder;

[0150] Step S3: Add zinc oxide, stearic acid and antioxidant 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com