A kind of sic composite coating for porous thermal insulation carbon material and preparation method thereof

A composite coating, carbon material technology, applied in the material field, achieves the effects of simple equipment process, low requirements on the surface of the base material and equipment, and avoiding direct reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

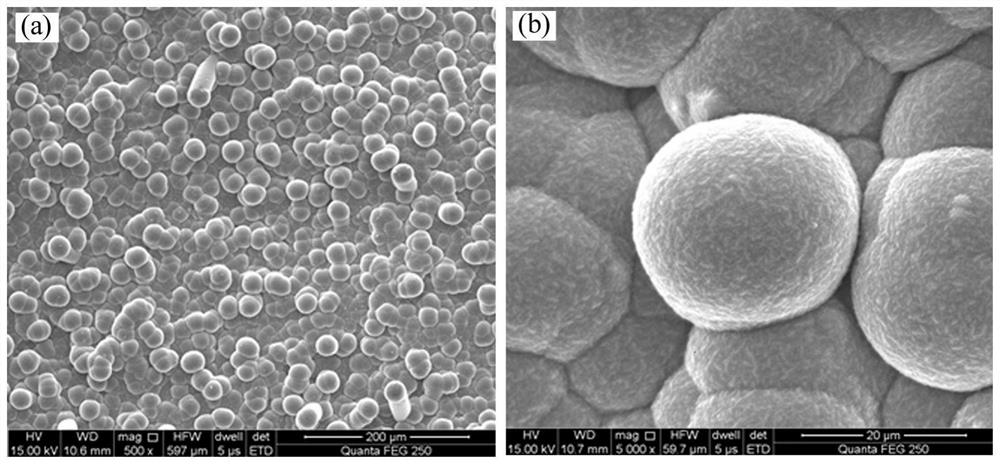

[0045] S1: First set the density to 0.20g / cm 3 The porous carbon felt was cut into small pieces, ultrasonically cleaned, and dried for later use. Dissolve 4g of carbon black and 16g of phenolic resin in 40ml of absolute ethanol, ultrasonically disperse for 10min, and magnetically stir for 30min to obtain a carbon black solution with uniform composition. The average particle diameter of the carbon black used was 24 nm. Brush the mixed solution evenly on the surface of the carbon felt, cure at 120°C for 2 hours, repeat the brushing for 6 times, cure and dry, put the sample into a high-temperature furnace, and pass in argon as a protective gas at a rate of 5°C / min Raise the temperature to 1000°C, keep it warm for 1 hour, and carry out carbonization treatment to prepare a pure carbon sealing layer on the surface of the carbon felt.

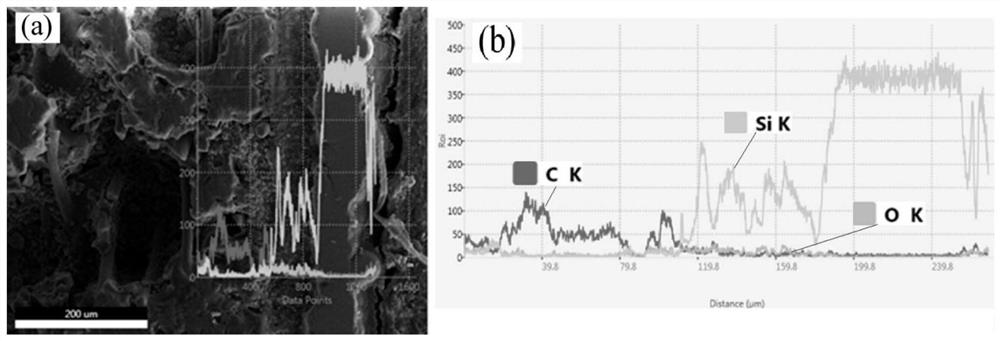

[0046]S2: Ultrasonic cleaning is performed on the carbon felt sample prepared with a carbon sealing layer for 30 minutes, and dried at 70°C for lat...

Embodiment 2

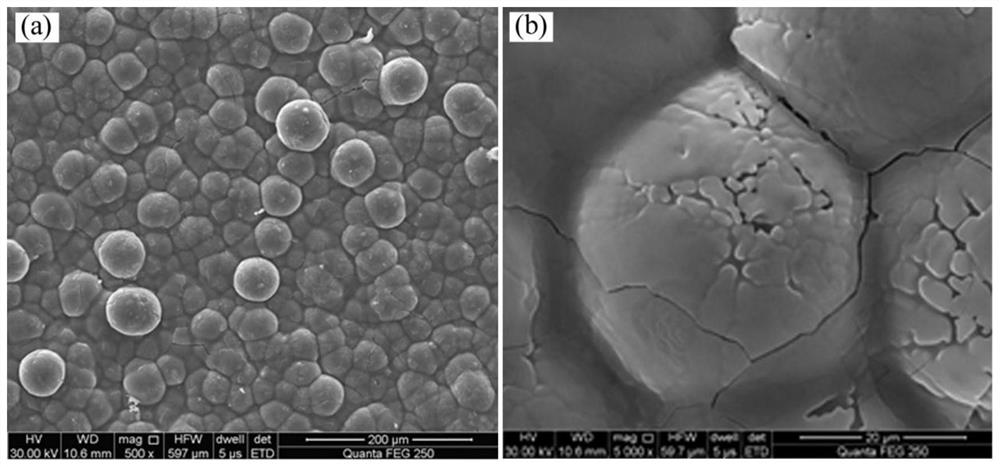

[0053] The preparation process is basically the same as that of Example 1, except that in S2, the amount of silicon powder is 2g.

[0054] The prepared SiC composite coating was tested for atmospheric oxidation resistance at 800°C. The results showed that after 65 minutes of atmospheric oxidation at 800°C, the weight loss rate of the porous carbon felt sample with SiC composite coating was 12.8%. After the felt sample was oxidized in the atmosphere at 800°C for 25 minutes, the weight loss rate of the porous carbon felt sample reached 40%, which further shows that the SiC composite coating can play a more obvious anti-oxidation protection effect on the porous carbon felt.

Embodiment 3

[0056] The preparation process is basically the same as in Example 1, except that in S2, the amount of silicon powder is 2.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com