Filter ceramics with precisely controllable dielectric constant for 5g base station and preparation method thereof

A dielectric constant and filter technology, which is applied in the field of filter ceramics and its preparation, can solve the problems of unstable filter performance and large error range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

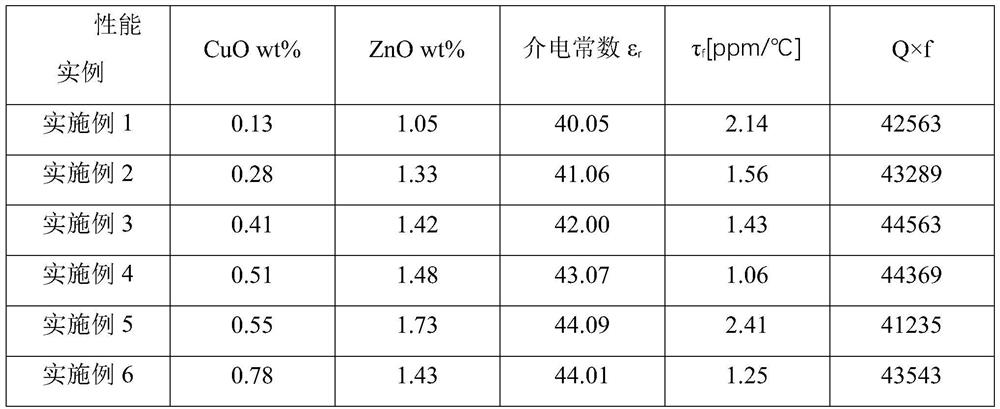

Examples

Embodiment 1

[0021] Step 1: MgO, TiO 2 , BaO, La 2 O 3 , Al 2 O 3 Weigh respectively: 12.12g, 107.11g, 80.02g, 162.96g, 101.96g;

[0022] Step 2: Put the prepared materials into a horizontal ball mill, wherein the weight ratio of powder, zirconia balls and deionized water is 1:4:1.5, and the ball is milled at 400r / min for 5-8 hours;

[0023] Step 3: Pre-sinter the evenly mixed raw materials in a high-temperature sintering furnace in an air atmosphere at 5°C / min to 800°C for 3 hours to obtain the main crystal phase of 0.75Mg 0.3 Ba 0.7 TiO 3 -0.25LaAlO 3 ;

[0024] Step 4: The main crystalline phase obtained in the previous step is crushed with a jet mill, and 10.341g of sintering aids, 85.449g of ZnO and 990g of deionized water are added in proportion to continue ball milling for 6h, and then dried at 80°C for 5h in an air atmosphere;

[0025] Step 5: add 3wt% polyvinyl alcohol binder for granulation, and press it into small discs with a diameter of 18mm and a height of 4mm under ...

Embodiment 2

[0028] Step 1: MgO, TiO 2 , BaO, La 2 O 3 , Al 2 O 3 Weigh respectively: 12.11g, 107.12g, 80.04g, 162.95g, 101.94g;

[0029] Step 2: Put the prepared materials into a horizontal ball mill, wherein the weight ratio of powder, zirconia balls and deionized water is 1:4:1.5, and the ball is milled at 400r / min for 5-8 hours;

[0030] Step 3: Pre-sinter the evenly mixed raw materials in a high-temperature sintering furnace in an air atmosphere at 5°C / min to 800°C for 3 hours to obtain the main crystal phase of 0.75Mg 0.3 Ba 0.7 TiO 3 -0.25LaAlO 3 .

[0031] Step 4: The main crystalline phase obtained in the previous step is crushed with a jet mill, and 22.274g of sintering aids, 108.235g of ZnO and 1020g of deionized water are added in proportion to continue ball milling for 6h, and then dried at 80°C for 5h in an air atmosphere;

[0032] Step 5: add 3wt% polyvinyl alcohol binder for granulation, and press it into small discs with a diameter of 18mm and a height of 4mm unde...

Embodiment 3

[0035] Step 1: MgO, TiO 2 , BaO, La 2 O 3 , Al 2 O 3 Weigh respectively: 12.11g, 107.15g, 80.04g, 162.93g, 101.91g;

[0036] Step 2: Put the prepared materials into a horizontal ball mill, wherein the weight ratio of powder, zirconia balls, and deionized water is 1:4:1.5, and the ball is milled at 400r / min for 5-8 hours;

[0037] Step 3: Pre-sinter the evenly mixed raw materials in a high-temperature sintering furnace in an air atmosphere at 5°C / min to 800°C for 3 hours to obtain the main crystal phase of 0.75Mg 0.3 Ba 0.7 TiO 3 -0.25LaAlO 3 .

[0038] Step 4: The main crystalline phase obtained in the previous step is crushed with a jet mill, and 32.615g of sintering aids, 115.559g of ZnO and 1100g of deionized water are added in proportion to continue ball milling for 6h, and then dried at 80°C for 5h in an air atmosphere;

[0039] Step 5: add 3wt% polyvinyl alcohol binder for granulation, and press it into small discs with a diameter of 18mm and a height of 4mm und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com