Composite activated low-calcium fly ash cement and preparation method thereof

A technology of low-calcium fly ash and fly ash, which is applied in the direction of cement production, etc., can solve the problems of not being able to meet the requirements of hydraulic cementitious materials, limit the application of fly ash, shrinkage and cracking of concrete, and improve the compactness and resistance Effects of corrosion, mitigation of non-renewable resources, early strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A composite activated low-calcium fly ash cement, comprising the following raw materials in parts by weight: 30 parts of fly ash, 20 parts of slag, 7 parts of anhydrite, 45 parts of ordinary Portland cement, KOH solution (30% by mass fraction) 3 parts, NaSO 4 (mass fraction 17%) 0.5 part, polycarboxylate high-performance water reducing agent 1 part and triethanolamine 0.5 part.

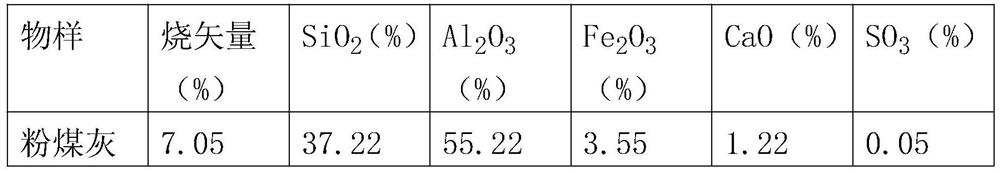

[0027] The selected fly ash components are shown in Table 1.

[0028] Table 1

[0029]

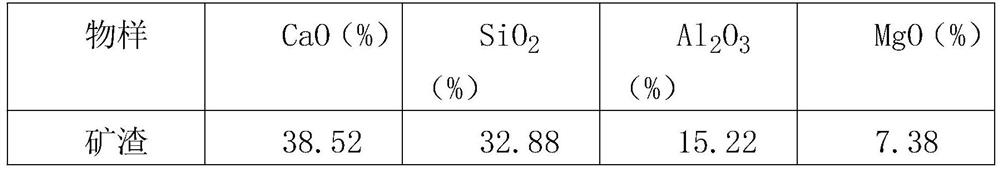

[0030] The selected slag composition is shown in Table 2.

[0031] Table 2

[0032]

[0033] A kind of preparation method of described composite activated low-calcium fly ash cement comprises the following steps:

[0034] (1) Add 30 parts by weight of fly ash to the ball mill, control the grinding time within 30 minutes, pulverize and sieve to obtain a specific surface area greater than 300m 3 / Kg of fly ash fine powder;

[0035] (2) Mix the fly ash fine powder ground in step (1) and 7 parts by ...

Embodiment 2

[0040] A composite activated low-calcium fly ash cement, comprising the following raw materials in parts by weight: 40 parts of fly ash, 10 parts of slag, 5 parts of anhydrite, 35 parts of ordinary portland cement, and NaOH solution (30% by mass fraction) 3 parts, NaSO 4 (mass fraction 17%) 0.5 parts, lignosulfonate 1 part and polyalcoholamine 0.5 parts.

[0041] The selected fly ash components are shown in Table 1.

[0042] Table 1

[0043]

[0044] The selected slag composition is shown in Table 2.

[0045] Table 2

[0046]

[0047] A kind of preparation method of described composite activated low-calcium fly ash cement comprises the following steps:

[0048] (1) Add 40 parts by weight of fly ash to the ball mill, control the grinding time within 30 minutes, pulverize and sieve to obtain a specific surface area greater than 300m3 / Kg of fly ash fine powder;

[0049] (2) Mix the fly ash fine powder ground in step (1) and 5 parts by weight of anhydrite into a muffle...

Embodiment 3

[0054] A composite activated low-calcium fly ash cement, comprising the following raw materials in parts by weight: 35 parts of fly ash, 15 parts of slag, 6 parts of anhydrite, 40 parts of ordinary Portland cement, and NaOH solution (30% by mass fraction) 3 parts, NaSO 4 (mass fraction 17%) 0.5 part, naphthalene series superplasticizer 1 part and ethylene glycol 0.5 part.

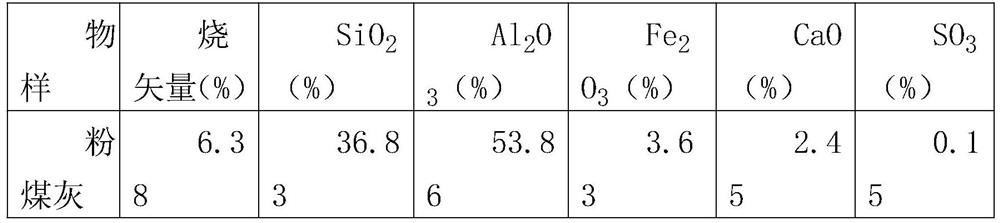

[0055] The selected fly ash components are shown in Table 1.

[0056] Table 1

[0057]

[0058] The selected slag composition is shown in Table 2.

[0059] Table 2

[0060]

[0061] A kind of preparation method of described composite activated low-calcium fly ash cement comprises the following steps:

[0062] (1) Add 35 parts by weight of fly ash to the ball mill, control the grinding time within 30 minutes, pulverize and sieve to obtain a specific surface area greater than 300m 3 / Kg of fly ash fine powder;

[0063] (2) Mix the fly ash fine powder ground in step (1) and 6 parts by weight of anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com