Rapid preparation method of polyglutamic acid for pesticide adjuvants

A technology of polyglutamic acid and pesticide adjuvant, applied in botanical equipment and methods, chemicals used for biological control, applications, etc. Water retention capacity, stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

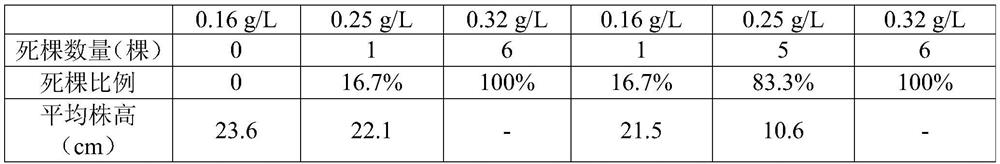

Examples

Embodiment 1

[0029] A kind of polyglutamic acid for pesticide adjuvant, its specific preparation steps:

[0030] Take 10L of polyglutamic acid fermentation stock solution, the content of polyglutamic acid in the polyglutamic acid fermentation stock solution is 3.5% (m / v), add phosphoric acid or concentrated sulfuric acid to adjust the pH to 2-3, stir at 70°C for 5 hours, and reduce the viscosity to 8mPa s, adjust pH5 with KOH solution;

[0031] Add 4wt% precipitant (the mass ratio of calcium nitrate and polyacrylamide in the precipitant is 1:1), continue to stir for 2h, and then centrifuge;

[0032] The separated supernatant is heated to 40°C, and then filtered with a ceramic membrane (the membrane pore size is 0.2 μm);

[0033] Add 1wt% precipitant to the filtered supernatant, stir for 2 hours, and then centrifuge;

[0034] The separated supernatant is treated with an ultrafiltration device (molecular weight cut-off is 20kDa), and the ultrafiltrate is added with 0.3% (m / v) potassium sor...

Embodiment 2

[0037] A kind of polyglutamic acid for pesticide adjuvant, its specific preparation steps:

[0038] Take 10L of polyglutamic acid fermentation stock solution, the content of polyglutamic acid in the polyglutamic acid fermentation stock solution is 4.5% (m / v), add phosphoric acid or concentrated sulfuric acid to adjust the pH to 2-3, stir at 80°C for 5 hours, and reduce the viscosity to 8mPa s, adjust pH5 with KOH solution;

[0039] Add 4wt% precipitant (the mass ratio of calcium nitrate and polyacrylamide in the precipitant is 1:2), continue to stir for 2h, and then centrifuge;

[0040] The separated supernatant is heated to 50°C, and then filtered with a ceramic membrane (the membrane pore size is 0.4 μm);

[0041] Add 2wt% precipitant to the filtered supernatant, stir for 2 hours, and then centrifuge;

[0042] The separated supernatant is treated with an ultrafiltration device (molecular weight cut off is 50kDa), and the ultrafiltrate is added with 0.3% (m / v) Cathone.

[...

Embodiment 3

[0045] A kind of polyglutamic acid for pesticide adjuvant, its specific preparation steps:

[0046] Take 10L polyglutamic acid fermentation stock solution, the content of polyglutamic acid in the polyglutamic acid fermentation stock solution is 4.0% (m / v), add phosphoric acid or concentrated sulfuric acid to adjust the pH to 2-3, stir at 75°C for 5 hours, and reduce the viscosity to 8mPa s, adjust pH5 with KOH solution;

[0047] Add 3wt% precipitant (the mass ratio of calcium nitrate and polyacrylamide in the precipitant is 1:2), continue to stir for 2h, and then centrifuge;

[0048]The separated supernatant is heated to 60°C, and then filtered with a ceramic membrane (the membrane pore size is 0.5 μm);

[0049] Add 1wt% precipitant to the filtered supernatant, stir for 2 hours, and then centrifuge;

[0050] The separated supernatant is treated with an ultrafiltration device (molecular weight cut-off is 10 kDa), and the ultrafiltrate is added with 0.4% (m / v) potassium sorbat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com