Porous nitrogen-boron co-doped carbon-based oxygen reduction catalyst and preparation method and application thereof

A co-doping, carbon-based oxygen technology, applied in the field of electrocatalysis and energy materials, can solve the problem of high cost, achieve the effect of wide application, excellent oxygen reduction catalytic performance, and increase electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The synthesis method of porous nitrogen and boron co-doped carbon nanotube oxygen reduction catalyst includes the following steps:

[0040]Step 1: Firstly, 100 mg of polypyrrole nanotube precursor and 10 mg of sodium tetraphenylborate are placed in a mortar and thoroughly ground for more than 15 minutes and mixed to obtain mixture A;

[0041]Step 2: Transfer the mixture A to the corundum boat and put it in the tube furnace, under the protection of argon hydrogen (5wt%), raise it from room temperature to 900°C at a heating rate of 2°C / min and keep it for 2 hours, after it is completely carbonized Naturally lower to room temperature to obtain material B;

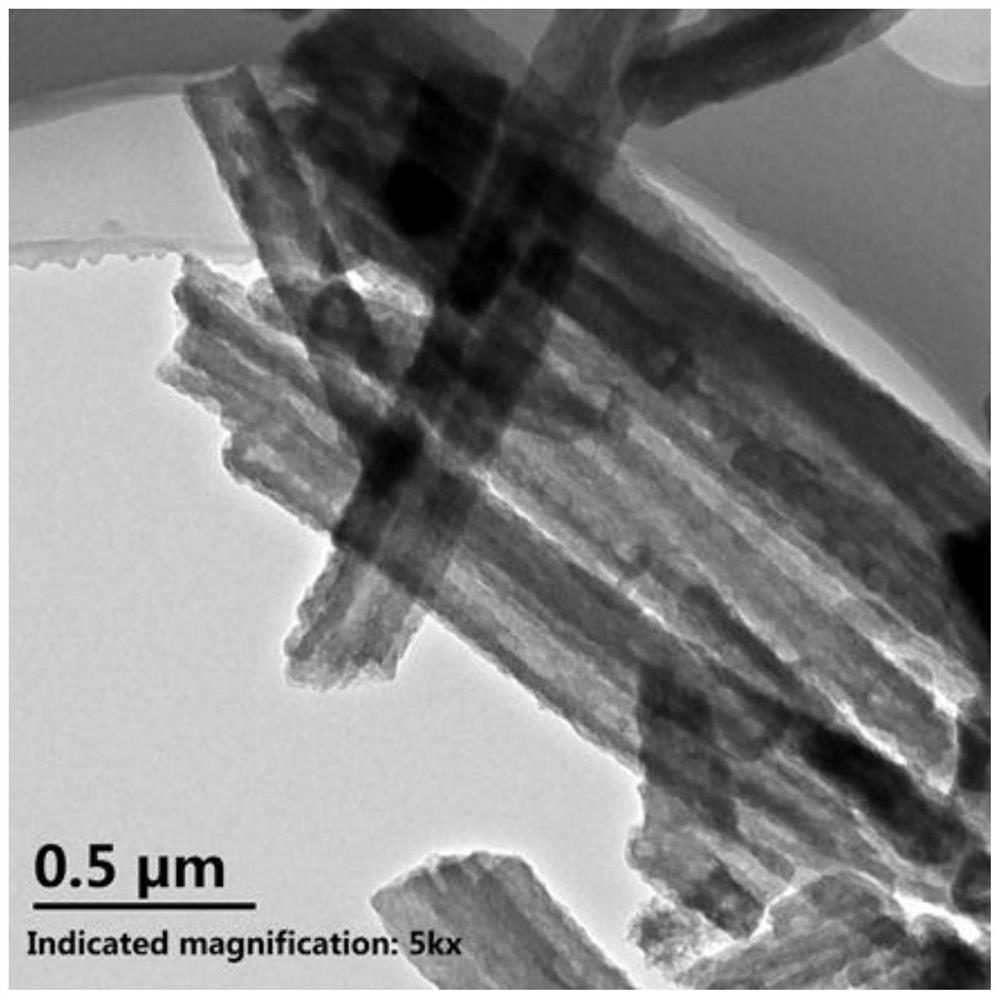

[0042]Step 3: Wash material B with deionized water until the filtrate is neutral, and then transfer it to a 60℃ blast drying oven to dry for 12 hours, such asfigure 1 As shown, the target product porous nitrogen and boron co-doped carbon nanotube oxygen reduction catalyst is obtained;

[0043]Step one in the above implementation case is o...

Embodiment 2

[0049]The synthesis method of porous nitrogen and boron co-doped carbon nanotube oxygen reduction catalyst includes the following steps:

[0050]Step 1: First, put 100mg of peptone precursor and 20mg of sodium tetraphenylborate in a mortar and grind thoroughly for more than 15 minutes and mix to obtain mixture A;

[0051]Step 2: Transfer the mixture A to the corundum boat and put it in the tube furnace, under the protection of nitrogen gas, raise it from room temperature to 800°C at a heating rate of 5°C / min and keep it for 2 hours. After being completely carbonized, it will naturally drop to room temperature. Material B;

[0052]Step 3: Wash the material B with deionized water until the filtrate is neutral, and then transfer it to a 60°C blast drying oven to dry for 12 hours to obtain the target product porous nitrogen-boron co-doped carbon oxygen reduction catalyst.

Embodiment 3

[0054]The synthesis method of porous nitrogen and boron co-doped carbon nanotube oxygen reduction catalyst includes the following steps:

[0055]Step 1: First, put 100mg of peptone precursor and 15mg of sodium tetraphenylborate in a mortar and grind thoroughly for more than 15 minutes and mix to obtain mixture A;

[0056]Step 2: Transfer the mixture A to the corundum boat and put it in the tube furnace, under the protection of nitrogen gas, raise it from room temperature to 800°C at a heating rate of 5°C / min and keep it for 2 hours. After being completely carbonized, it will naturally drop to room temperature. Material B;

[0057]Step 3: Wash material B with deionized water until the filtrate is neutral, and then transfer it to a 60°C blast drying oven for 12 hours to obtain the target product porous nitrogen-boron co-doped carbon-oxygen reduction catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com