Medicinal neutral borosilicate glass melting furnace capable of homogenizing and clarifying

A borosilicate glass and glass melting furnace technology, which is applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problems that the mixing system is difficult to cover the melting furnace, high maintenance cost, and high price, so as to reduce construction and Maintenance cost, improvement of production efficiency, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

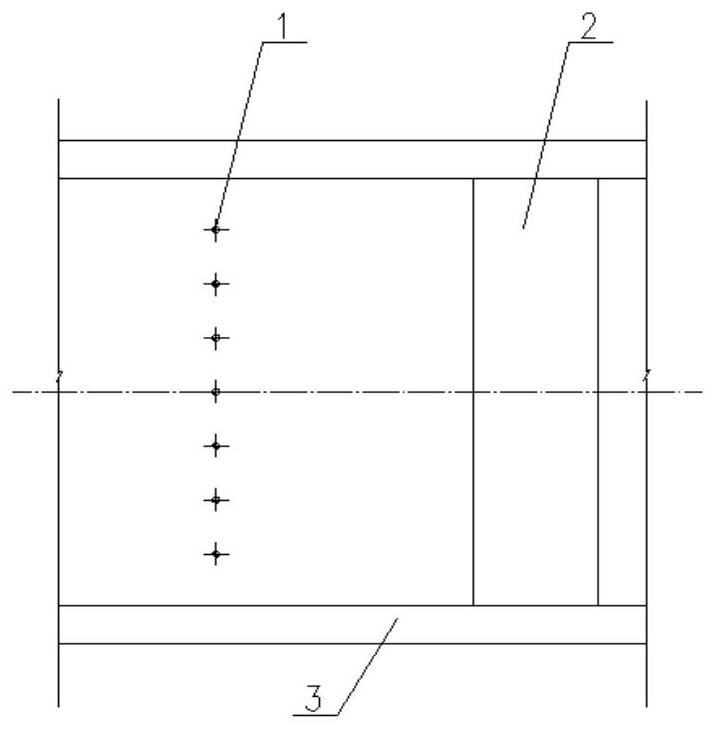

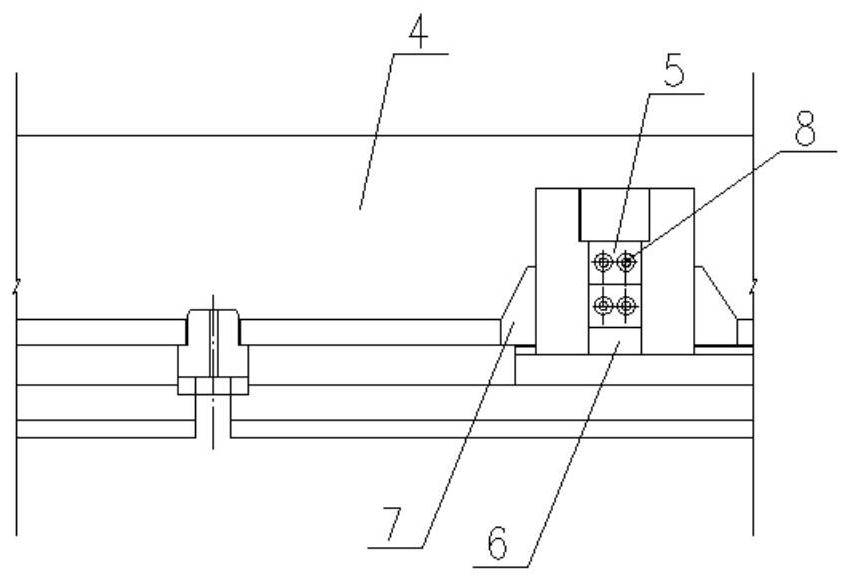

[0026] Such as figure 1 with figure 2 As shown, this embodiment provides a pharmaceutical neutral borosilicate glass melting furnace that can be homogenized and clarified. The glass melting furnace is full oxygen combustion + electric auxiliary heating. A water-cooled bubbling system 1 is provided at the bottom, and the medium is oxygen with a purity of 99%; downstream of the bubbling system 1, a bubbling kiln 2 with a width of 600mm-1400mm is provided, and molten neutral borosilicate glass The liquid 4 is located in the melting pool surrounded by the pool wall bricks 3. The middle of the foam-discharging kiln sill 2 is a perforated brick 5, and the bottom is a kiln sill pad 6. The upper and lower sides of the perforated brick 5 are equipped with a The wedge-shaped kiln sill is covered with bricks 7, and a cooling water bag 8 is placed in the middle of the perforated brick 5, that is, the foam-discharging kiln sill 2 is composed of three fused high-zirconium bricks made of z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com