Low-voltage switch cabinet

A low-voltage switchgear and cabinet body technology, which is applied in the direction of pull-out switchgear, switchgear, switchgear components, etc., can solve the problem of not being able to effectively deal with abnormal heating of the switchgear, achieve smooth engagement or disengagement, and reduce damage The probability of, the effect of slowing down the movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

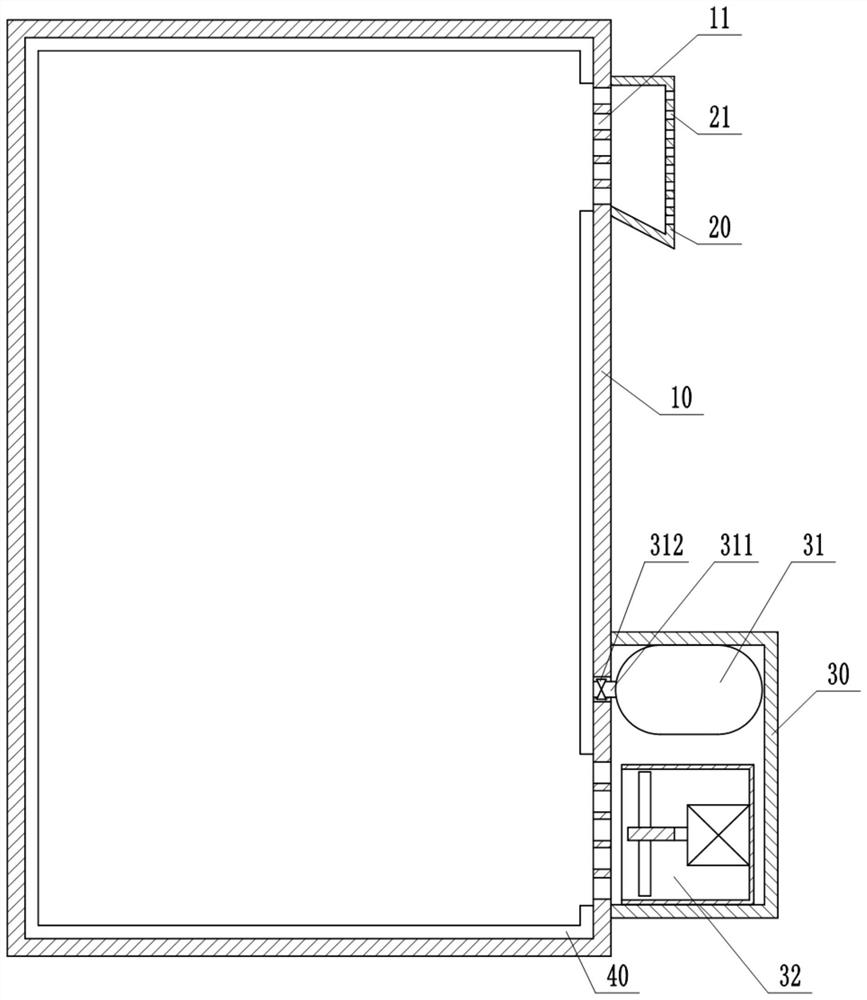

[0027] This embodiment is basically as figure 1Shown: a low-voltage switchgear cabinet body, including a cabinet body 10 and a drawer 50 that can be drawn relative to the cabinet body 10. The cabinet body 10 is obtained by processing aluminum-zinc coated plates, which have high hardness and are not easily deformed. , has the characteristics of corrosion resistance and oxidation resistance, and it is more suitable to process the cabinet body 10 with an aluminum-zinc coated plate. The side wall of the cabinet body 10 is provided with a heat dissipation port 11, the outer wall of the cabinet body 10 is welded with a buffer chamber 20 opposite to the heat dissipation port 11, and the side wall of the buffer chamber 20 opposite to the heat dissipation port 11 is provided with a heat dissipation hole 21 . The bottom of the buffer chamber 20 is inclined downward to the side away from the cabinet body 10. After external dust and rainwater enter the buffer chamber 20, it will move awa...

Embodiment 2

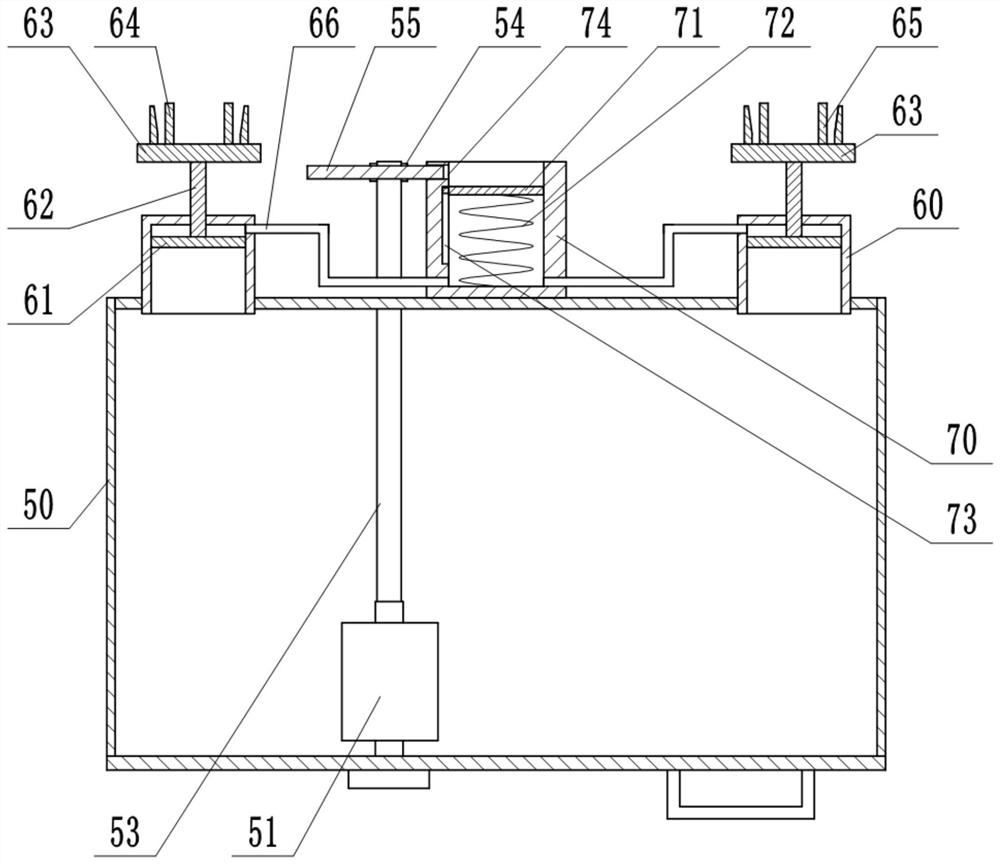

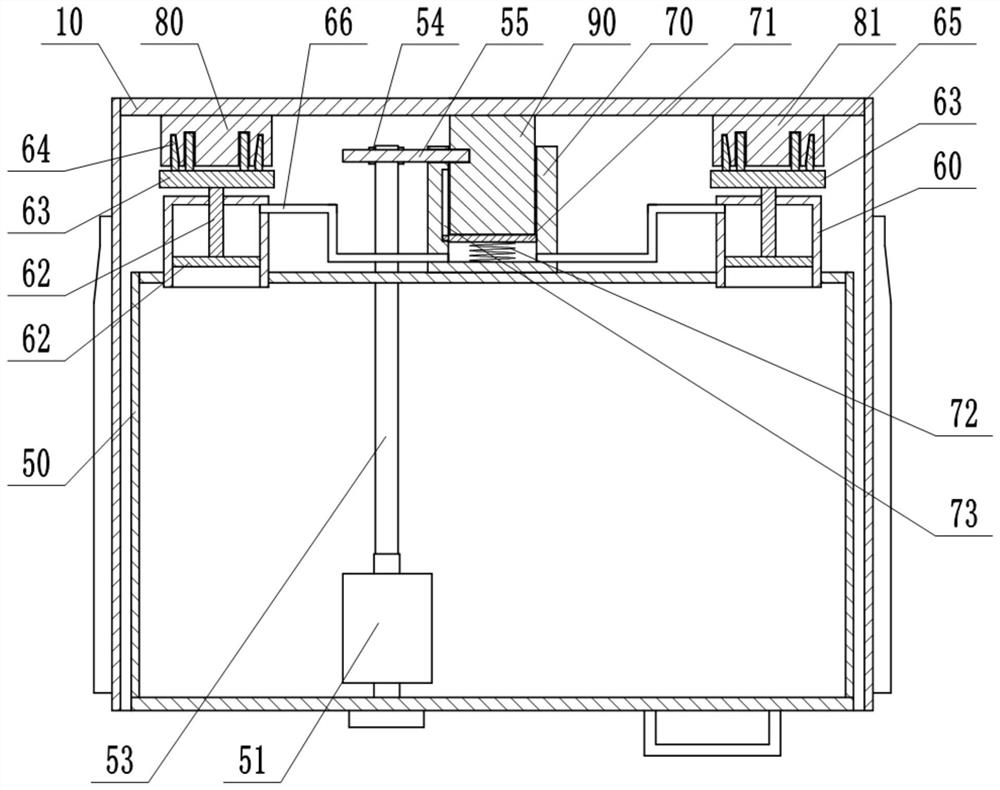

[0031] The difference between this embodiment and Embodiment 1 is that: figure 2 , 3 As shown, a piston cylinder 60 is fixedly installed on both sides of the rear side wall of the drawer 50 , and one end of the piston cylinder 60 close to the drawer 50 is opened. A piston 61 is slidably and sealedly connected to the piston cylinder 60, and a support rod 62 passing through the piston cylinder 60 and capable of sealing connection with the piston cylinder 60 is fixed on the piston 61, and a mounting seat 63 located outside the piston cylinder 60 is welded on the support rod 62 , one of the mounting bases 63 is fixedly installed with an incoming moving contact 64, and the other mounting base 63 is fixedly installing an outgoing moving contact 65. A sleeve 70 is also fixed on the rear side wall of the drawer 50. The sleeve 70 is fixed between the two piston cylinders 60. The end of the sleeve 70 is open away from the drawer 50. The sleeve 70 is filled with hydraulic oil. A seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com