Preparation method of pressure sensor based on composite sponge porous structure

A pressure sensor and composite sponge technology, applied in the sensor field, can solve the problems of low sensitivity of flexible pressure sensors, cannot be applied to wearable devices, expensive materials, etc., achieve high market value and industrialization potential, low price, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

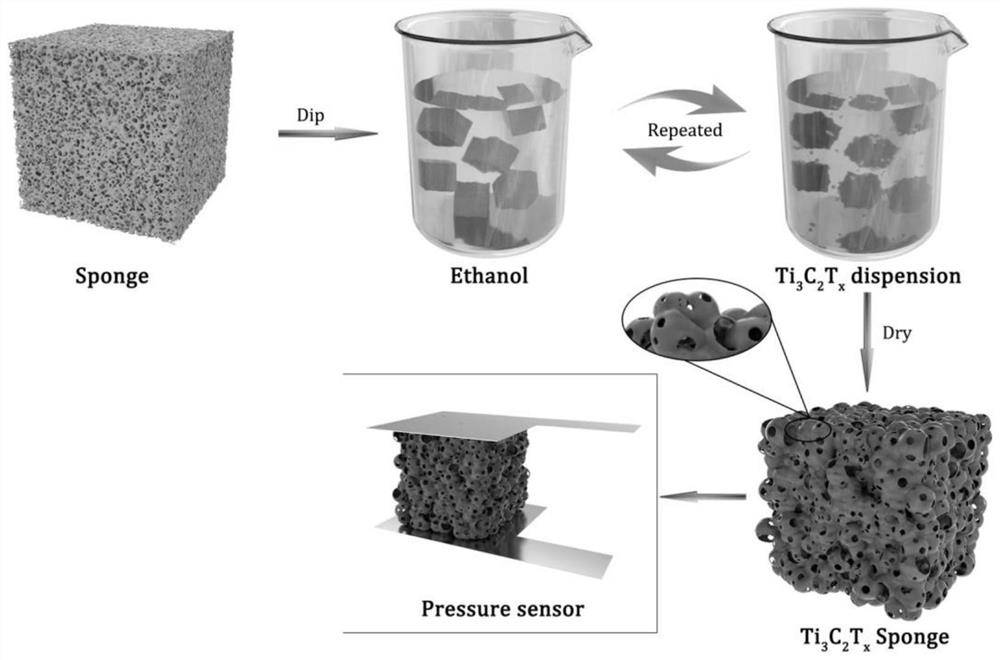

[0018] see Figure 1-2 , a kind of preparation method of the pressure sensor based on composite sponge porous structure of the present invention, pressure sensor comprises electrode, composite sponge, and electrode is a kind of in aluminum bar, silver wire, copper sheet, and electrode is bonded to composite sponge by silver paste The top and bottom of ; the porous structure composite sponge and electrodes were connected with silver paste to increase conductivity. The preparation method comprises the following steps:

[0019] (1) Soak the sponge made of styrene-butadiene rubber with alcohol for 5-10 minutes to clean it;

[0020] (2) Place the cleaned styrene-butadiene rubber sponge in the Mxene solution for repeated soaking and squeezing to obtain a composite sponge; the concentration of the Mxene solution is 2 mg / mL-5 mg / mL. Mxene in Mxene solution is Ti 2 C.Ti 3 C 2 、Mo 2 C.Mo 2 TiC 2 、Mo 2 Ti 2 C 3 One of. Mxene material is an emerging two-dimensional layered str...

Embodiment 1

[0025] Cut the sponge made of styrene-butadiene rubber into 2cm×2cm, put it in a petri dish, soak it in alcohol for 5-10 minutes to clean;

[0026] The cleaned sponge made of styrene-butadiene rubber was placed in a Mxene solution with a concentration of 5 mg / mL, soaked and squeezed repeatedly to obtain a composite sponge. Mxene in Mxene solution is Ti 3 C 2 .

[0027] Dry the composite sponge in a fume hood.

[0028] The top and bottom of the dried composite sponge are coated with silver paste and bonded with aluminum strip electrodes to obtain a pressure sensor based on the porous structure of the composite sponge. The pressure sensor based on the porous structure of the composite sponge has a thickness of about 2 cm and an area of about 4 cm. 2 .

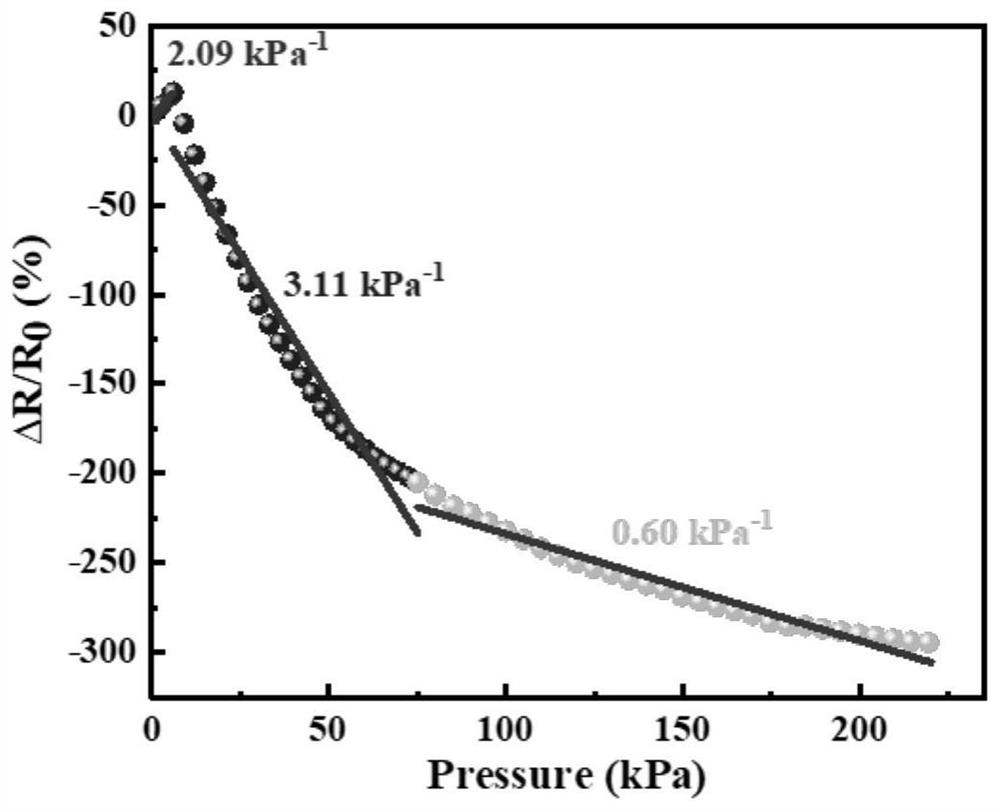

[0029] Connect the pressure sensor based on the porous structure of the composite sponge to the test circuit, apply pressure with a tension and pressure tester, and record the resistance value with a digital multimeter.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com