A kind of luminous warning road reflective paint and its construction method

A technology of reflective paint and construction method, applied in reflective/signal paint, roads, roads and other directions, can solve the problems of poor quality of traffic marking coating and high maintenance cost, achieve good reflective effect, reduce maintenance cost and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

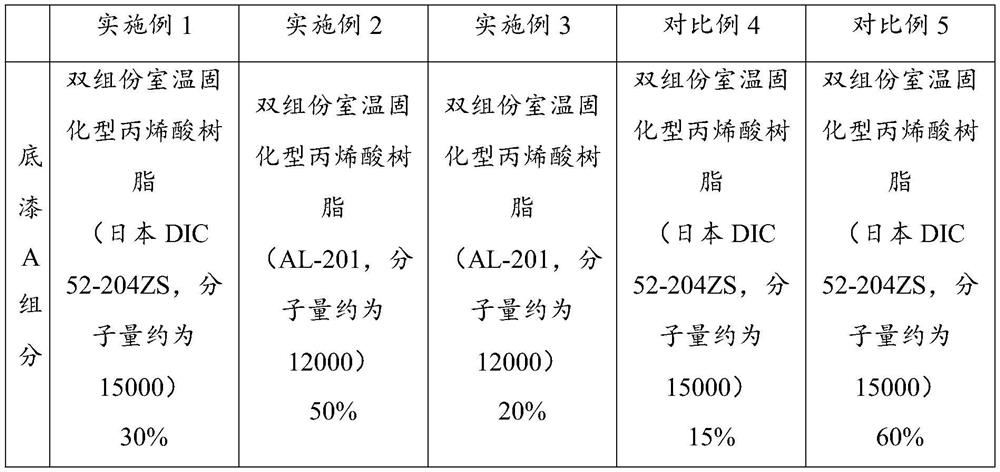

Embodiment 1

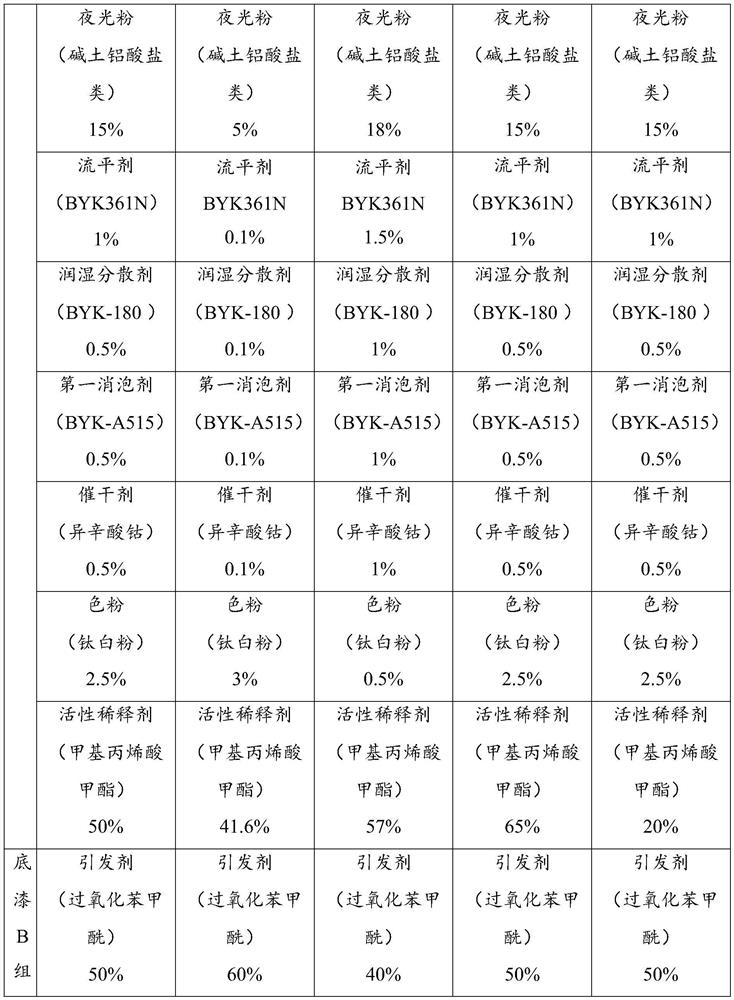

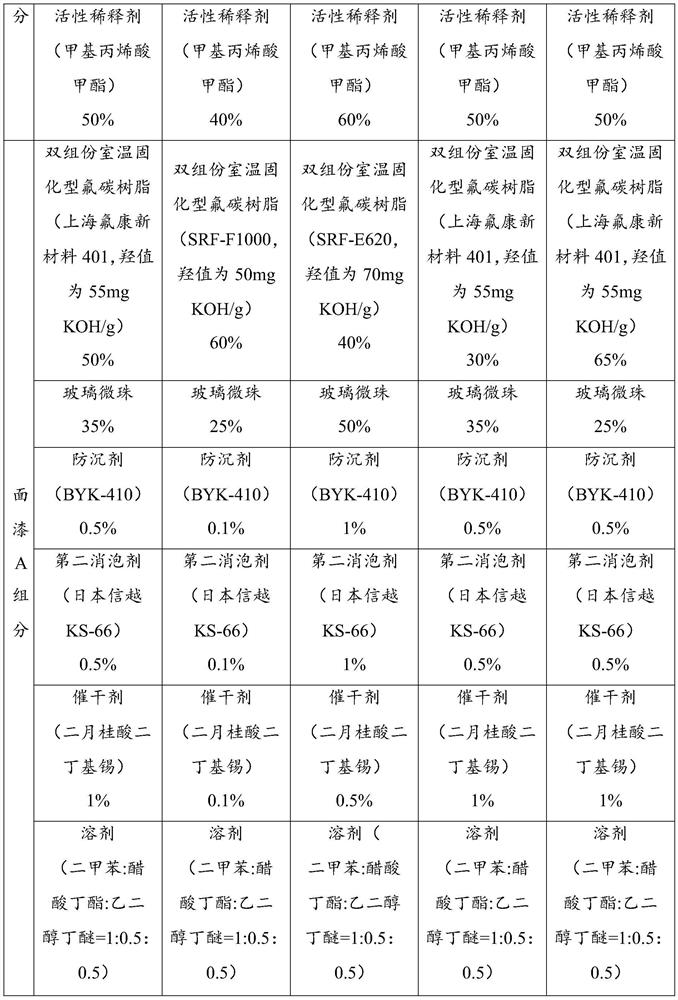

[0045] This embodiment provides a kind of luminous warning type road reflective paint, is made up of primer and finish paint;

[0046] The primer includes a primer A component and a primer B component. By weight percentage, the primer A component includes: two-component room temperature curing acrylic resin (Japan DIC 52-204ZS, molecular weight is about 15000) 30%, Luminous powder (alkaline earth aluminate) 15%, leveling agent (BYK361N) 1%, wetting and dispersing agent (OBYK-180) 0.5%, first defoamer (BYK-A515) 0.5%, drier ( Cobalt isooctanoate) 0.5%, toner (titanium dioxide) 2.5%, reactive diluent (methyl methacrylate) 50%, primer B component includes: initiator (benzoyl peroxide) 50%, reactive diluent Agent (methyl methacrylate) 50%;

[0047] The topcoat includes topcoat A component and topcoat B component. In terms of weight percentage, topcoat A component includes: two-component room temperature curing fluorocarbon resin (Shanghai Fluorine New Material 401 with a hydroxyl...

Embodiment 2

[0055] This embodiment provides a kind of luminous warning type road reflective paint, is made up of primer and finish paint;

[0056] The primer includes primer A component and primer B component, and the content of each component is shown in Table 1.

[0057] The construction method provided by this embodiment is consistent with Example 1, the difference is that in the process of preparing the primer, the mass ratio of the primer A component to the primer B component is 1:0.005, after curing, the dry film of the primer The thickness is 300μm; in the process of preparing the topcoat, the mass ratio of component A of the topcoat to component B of the topcoat is 1:0.1, and after curing, the dry film thickness of the topcoat is 60μm. The performance of the coating was tested after 72 hours of construction, and the test results are shown in Table 2.

Embodiment 3

[0059] This embodiment provides a kind of luminous warning type road reflective paint, is made up of primer and finish paint;

[0060] The primer includes primer A component and primer B component, and the content of each component is shown in Table 1.

[0061] The construction method provided by this embodiment is consistent with Example 1, the difference is that in the process of preparing the primer, the mass ratio of the primer A component to the primer B component is 1:0.02, after curing, the dry film of the primer The thickness is 100μm; in the process of preparing the topcoat, the mass ratio of topcoat A component to topcoat B component is 1:0.3, and after curing, the dry film thickness of the topcoat is 40μm. The performance of the coating was tested after 72 hours of construction, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com