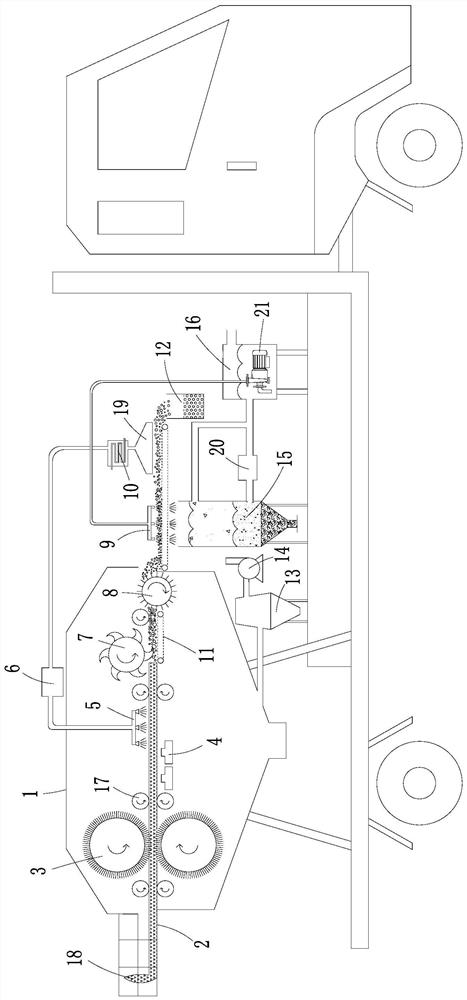

A cleaning device and method for resource recovery of waste filter bags

A cleaning device and recycling technology, which is applied in the field of cleaning devices for resource recycling of waste filter bags, can solve the problems of unsatisfactory application effect and difficult hardening dust removal, etc., and achieve improved cleaning effect, good effect and reduced cleaning load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The waste filter bag 18 that needs to be processed is an "aramid fiber surface layer / aramid base cloth" needle felt filter bag, which is used in the bag filter for flue gas purification at the cement kiln head. When the discarded filter bag 18 reaches the end of its life cycle, if it is landfilled as solid waste, not only the processing cost is high, but also secondary pollution will be caused. Therefore, the above waste filter bags 18 can be cleaned and recycled to produce heat-insulating and flame-retardant aramid paper, which can bring considerable economic benefits. The dust agglomeration of the filter bag used in the cement kiln head is not much, and the dust on the surface of the filter bag is relatively loose, but the internal dust is clogged. The cleaning process for above-mentioned discarded filter bag 18 is as follows:

[0058] Step 1: Send the waste filter bag 18 into the negative pressure ash chamber 1 through the feeding platform 2, until the waste filter ...

Embodiment 2

[0065] The waste filter bag 18 that needs to be processed is a "polyphenylene sulfide conventional fiber + superfine fiber surface layer / polyphenylene sulfide base cloth" needle felt filter bag, which is used in the bag filter for flue gas purification in coal-fired power plants . When the discarded filter bag 18 reaches the end of its life cycle, the discarded filter bag 18 can be cleaned and recycled to make automobile brake pads, which are wear-resistant and heat-resistant, and can bring considerable economic benefits. Coal-fired power plants often have working conditions below the dew point, resulting in serious dust compaction on the surface of the filter bag. In this embodiment, the vehicle-mounted mobile installation is adopted, and the special vehicle can be driven directly to the site of the coal-fired power plant, and at the same time, the power supply, compressed air, and water can all be connected with the on-site pipeline. The cleaning process for above-mention...

Embodiment 3

[0073] The waste filter bag 18 that needs to be processed is a "polyimide fiber surface layer / polyimide base cloth" needle-punched felt filter bag, which is used in the bag filter for iron-making blast furnace gas purification in iron and steel enterprises. When the discarded filter bag 18 reaches the end of its life cycle, if it is landfilled as solid waste, not only the processing cost is high, but also secondary pollution will be caused. Therefore, the above waste filter bags 18 can be cleaned and recycled to produce super temperature-resistant engineering plastics above 240° C., which can bring considerable economic benefits. The dust agglomeration on the surface of the filter bag used for ironmaking blast furnace gas purification is not serious, and the dust is relatively fine, so it is easy to enter the inside of the filter material layer and cause jamming. The cleaning process for above-mentioned discarded filter bag 18 is as follows:

[0074] Step 1: Send the waste fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com