A kind of mixed organic solvent for preparing high-temperature sintered conductive paste

A conductive paste and organic solvent technology, applied in the field of oily organic solvents, can solve the problems of slow volatilization, achieve stable volatilization, good solubility, and improve affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] It is made of the following raw materials:

[0024] Ethylene glycol monohenyl ether acetate 60 wt%;

[0025] Butylkar sollenate 10 wt%;

[0026] 2,2,4-trimethyl-1,3-pentanediol monoisutyrate 5.4% by weight;

[0027] Dimethyl adipate 24 wt%;

[0028] γ-methacryloxypropyl trimethoxysilane 0.1% by weight;

[0029] Silicone oil 1.0% by weight;

[0030] The ethylene glycol monoshenyl ether acetate is prepared from the following materials and methods:

[0031] The molar ratio of ethylene glycol single-phenyl ether and acetic anhydride is 1: 1.5, toluene 20 wt%, and the sulfonic acid-based molecular sieve;

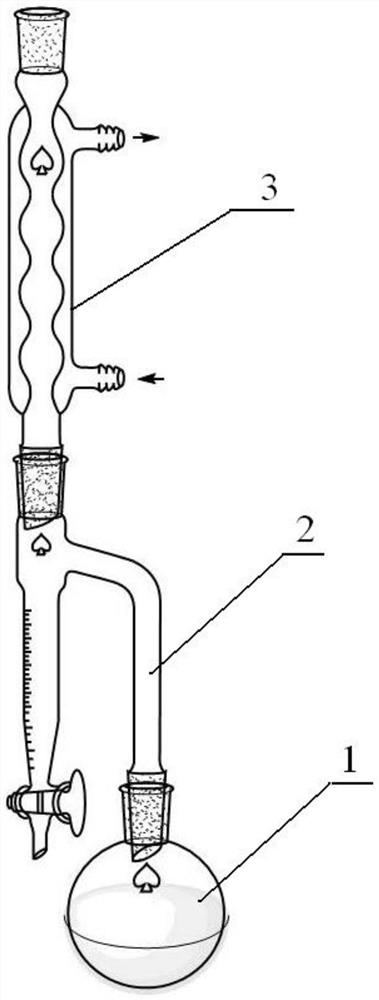

[0032] A moisture 2, a spherical condensed tube 3, a spherical condensed tube 3, and a magnetic stirring condition in a round bottom flask 1, and the toluene is heated to the toluene reflux, and the toluene is stable and refluxed. Cooled to room temperature, distilled, and the main fraction was charged.

Embodiment 2

[0034] It is made of the following raw materials:

[0035] Slithenyl ether acetate 10 wt%;

[0036] 60% by weight of butylkin alcoholacerate;

[0037] 2,2,4-trimethyl-1,3-pentanediol diisobutyrate 1 wt%;

[0038] Dimethyl adipate 2%;

[0039] γ-methacryloxypropyl trimethoxysilane 0.5% by weight;

[0040] 0.5 wt% of silicone oil.

[0041] The propylene glycol monoshenyl ether acetate according to the present invention is prepared from the following raw materials and methods:

[0042] The molar ratio of propylene glycol monoenzene ether and acetic anhydride is 1: 1.1, toluene 15 wt%, a moderate amount of sulfonic acid-based molecular sieve;

[0043] Detainer 2, spherical condensed tube 3, magnetic stirring conditions in the round bottom flask 1, and the toluene is heated to toluene reflux, and the toluene is stable and refluxed; remove the moisture, add a dryer; to be mixed Cooled to room temperature, distilled, and the main fraction was charged.

Embodiment 3

[0045] It is made of the following raw materials:

[0046] A monophhenylene ether oxide of propylene glycol is 35 wt%;

[0047] Butylkin alcohol acetate 35 wt%;

[0048] 2,2,4-trimethyl-1,3-pentanediol monoibutyrate 5 wt%, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate 5 wt%;

[0049] Ethylene dimethyl diethyl ester;

[0050] γ-methylpropionyloxypropyl trimethoxysilane 0.3% by weight;

[0051] Silicone oil 1.5 wt%.

[0052] The propylene glycol monophenyl ether oxide according to the present invention is prepared from the following raw materials and methods:

[0053] The molar ratio of propylene glycol monoenzene ether to butyric anhydride is 1: 1.3, toluene 10 wt%, a moderate amount of sulfonic acid-based molecular sieve;

[0054] Adding a moisture 2, a spherical condensed tube 3, a magnetic stirring condition in a round bottom flask 1, a toluene reflux, retaining toluene, removing a moisture, and add a dryer; Cooled to room temperature, distilled, and the main fraction was charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com