Particle input amount calculation method based on selenium removal model, and application thereof

A calculation method and particle technology, applied in the field of pollutant removal, can solve the problems of unstable control effect of selenium pollutants, high operating costs, unsuitable for the current situation of coal-fired pollutant control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

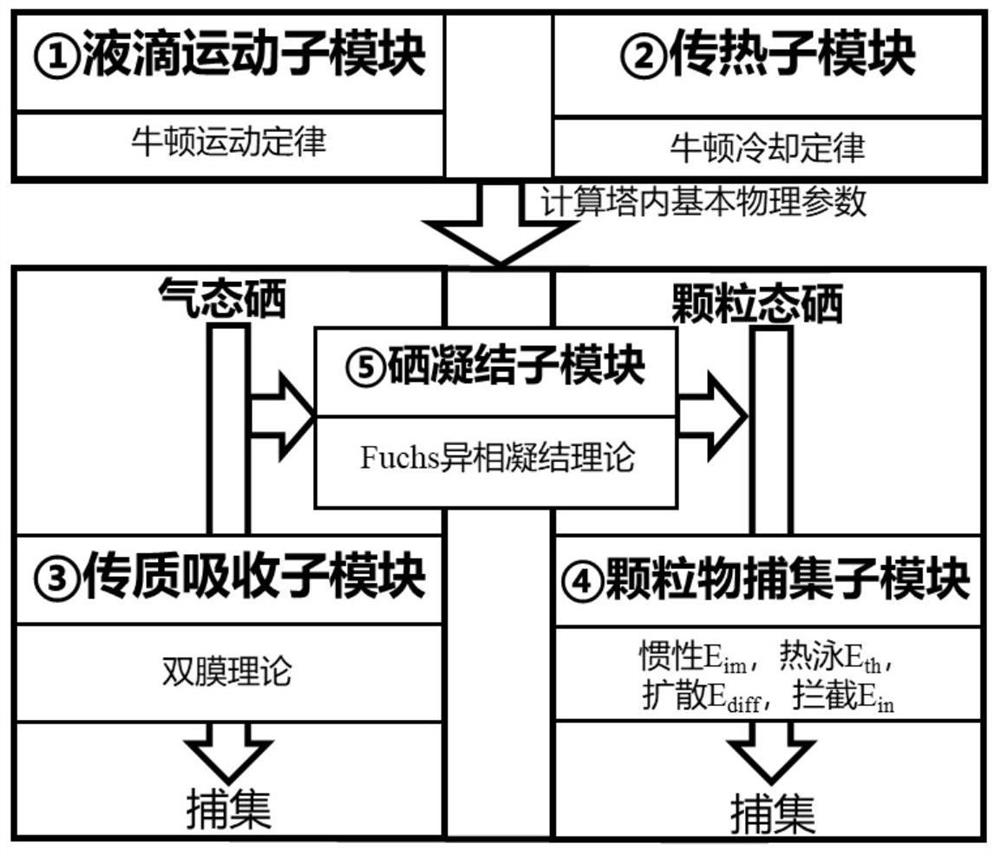

AI Technical Summary

Problems solved by technology

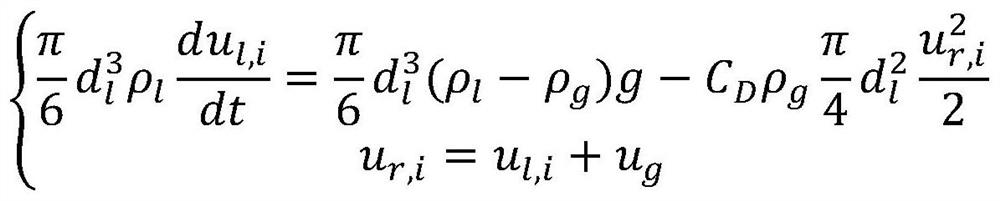

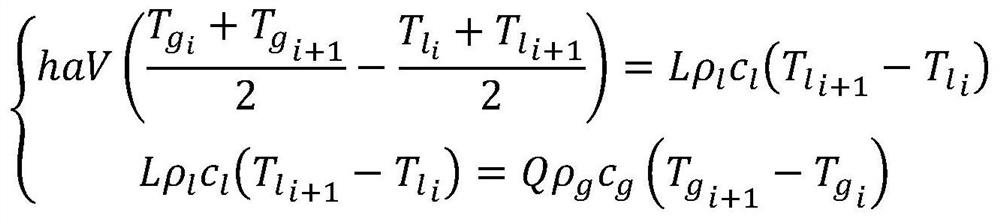

Method used

Image

Examples

Embodiment 1

[0176] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 1750000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 87μg / m 3 , the concentration of primary particulate matter is 5.3mg / m 3 , the characteristic particle size of primary particulate matter is 1.3 μm, the flue gas temperature at the inlet is 114 °C, the slurry temperature inside the desulfurization tower is 57 °C, and the liquid-gas ratio of the desulfurization tower is 20.

[0177] Operation process: collect fly ash from the No. 1 electric field ash hopper of the power plant electrostatic precipitator, screen and separate fly ash particles with a particle size below 20 μm, take the remaining fly ash for particle size analysis, and measure its characteristic particle size to be 37 μm; the fly ash The particles are fed in at a constant speed from the front flue of the booster fan at the entrance of the desulfurization tower a...

Embodiment 2

[0180] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 2230000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 64μg / m 3 , the concentration of primary particulate matter is 3.4mg / m 3 , the characteristic particle size of the primary particulate matter is 0.6 μm, the flue gas temperature at the inlet is 98 °C, the slurry temperature inside the desulfurization tower is 53 °C, and the liquid-gas ratio of the desulfurization tower is 15.

[0181] Operation process: Use a uniform feeder to feed silica particles with a characteristic particle size of 25 μm at a rate of 8.9 kg / h from the flue in front of the booster fan at the entrance of the desulfurization tower at a constant speed.

[0182] After adding particles to the inlet of the desulfurization tower in this embodiment, the selenium concentration at the outlet of the desulfurization tower is 5 μg / m 3 , the particle concentration i...

Embodiment 3

[0184] Application object: a wet flue gas desulfurization device in a power plant, the inlet flue gas volume is 3760000m 3 / h (standard state, wet basis), the selenium concentration in the inlet flue gas is 342μg / m 3 , the concentration of primary particulate matter is 13.2mg / m 3 , the characteristic particle size of the primary particulate matter is 13.2 μm, the flue gas temperature at the inlet is 107 °C, the slurry temperature inside the desulfurization tower is 56 °C, and the operating liquid-gas ratio of the desulfurization tower is 16.

[0185] Operation process: Use a uniform feeder to feed calcium oxide particles with a characteristic particle size of 100 μm at a rate of 94kg / h from the flue in front of the booster fan at the entrance of the desulfurization tower at a constant speed.

[0186] After adding particles to the inlet of the desulfurization tower in this embodiment, the selenium concentration at the outlet of the desulfurization tower is 9 μg / m 3 , the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com