Low-power-consumption scheduling method based on high-performance open type numerical control system

A technology of numerical control system and scheduling method, which is applied in the directions of energy-saving calculation, program control design, climate sustainability, etc., and can solve the problems of rising power consumption of the system as a whole, lack of time-energy judgment conditions, time and energy consumed without consideration, etc. problem, to achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

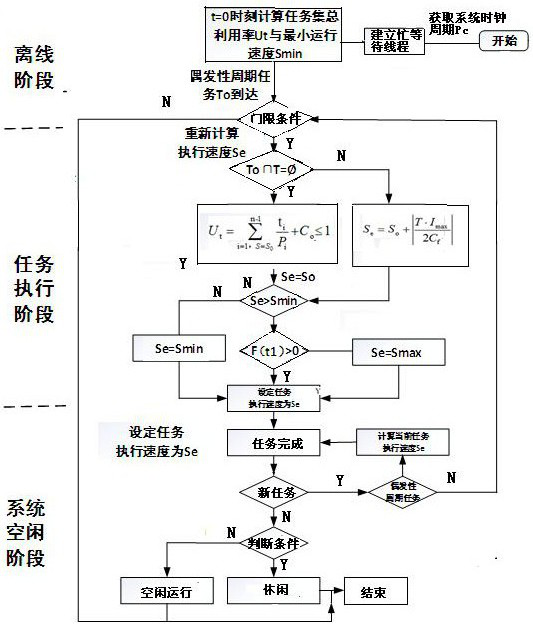

[0034] Reference attached figure 1 , the low-power scheduling method is divided into three stages: offline stage, task execution stage, and system idle stage. According to the characteristics of sporadic periodic tasks generated by high-performance CNC systems, low-power scheduling in different stages is realized. Occasional periodic tasks are a type of real-time tasks. In high-performance CNC systems, they are often generated by modules equipped with intelligent algorithms. Their characteristics are similar to periodic tasks, that is, the release interval between two continuous task instances is a fixed constant. The difference is that Occasional periodic tasks will have a certain life cycle. During the survival period of the task, it has the characteristics of periodic tasks. After the life cycle ends, it is similar to the occasional task;

[0035] At t=0, the busy waiting thread System Idle (wait) is established according to the system clock cycle Pc, and the power consumpt...

Embodiment 2

[0038] Two queues are set up on the real-time scheduler: the task completion queue (done queue) represents the set of tasks that have been completed in the task set, and the set FT (T fi , t f ) means; the task ready queue (ready queue) contains a set of tasks that are ready but not yet scheduled, and the set RT (T i , t) said.

[0039] Periodic task T at time t o (p o , t o ) comes, according to the threshold condition, when t o ≤left( t )-, it is inserted into the ready task queue according to the earliest deadline priority principle.

[0040] when sporadic periodic tasks T o ( p o , t o ) is ready at time t, the sporadic periodic task replaces the task in the original preparation queue, and the total utilization rate of the CPU at this time, then the execution speed of the CPU at this time is S e =S 0 ;

[0041] Execution speed if sporadic periodic tasks are a new subset of the prepare queue.

[0042] A complete clock cycle should be composed of the followi...

Embodiment 3

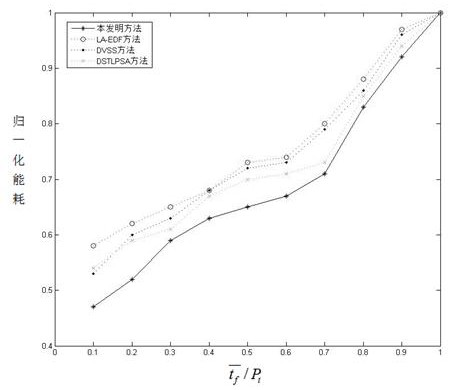

[0048] figure 2 In the present invention, is the average actual execution time of the task and the clock cycle P t The simulation experiment result diagram of the influence of ratio on energy consumption. The comparison algorithms are the existing LA-EDF algorithm, DVSST algorithm and DSTLPSA algorithm. The abscissa is, and the ordinate is the normalized energy consumption. When the proportion of the clock cycle gradually increases, the average idle time of the task set will decrease, and the energy consumption of the above algorithms will gradually increase. It can be seen that the performance of the algorithm proposed by the present invention is always better than other algorithms, and the calculation shows that this algorithm saves about 15% of energy consumption on average compared with other algorithms.

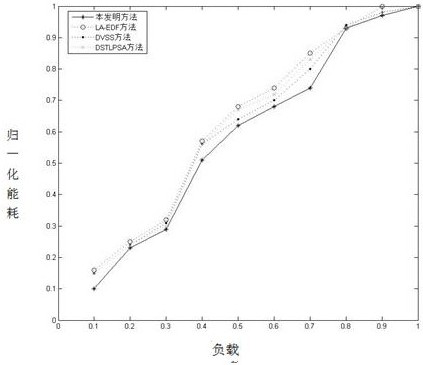

[0049] image 3 It is a simulation experiment result diagram of the influence of system utilization rate change on energy consumption in the present invention. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com