Alloy material flange and preparation method thereof

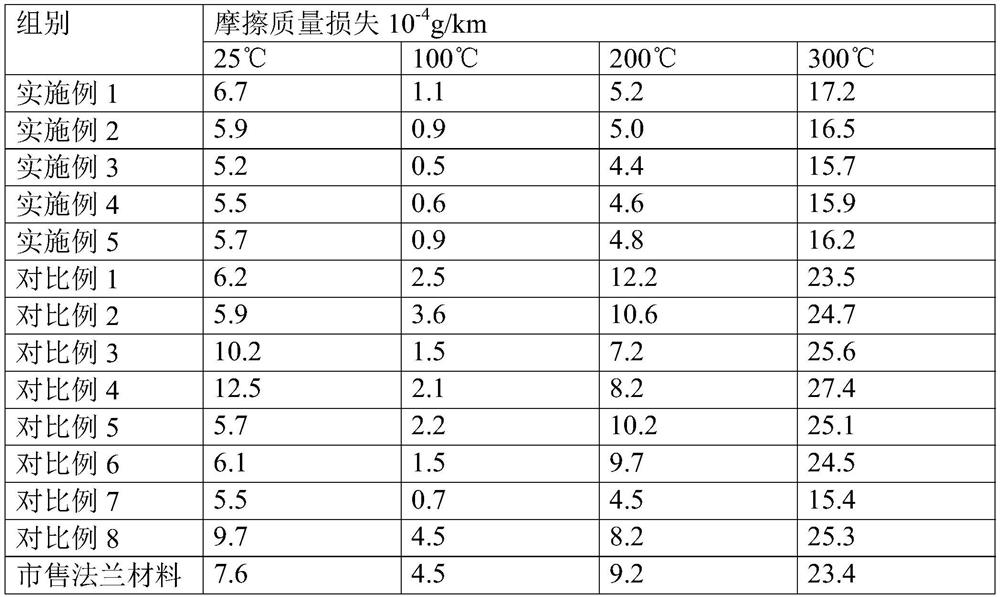

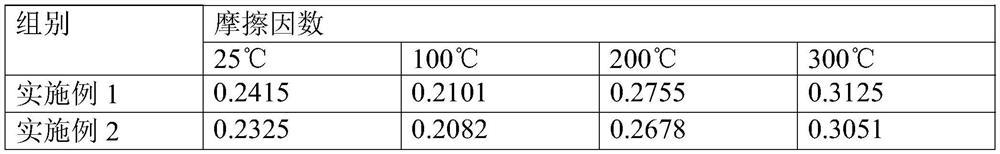

A technology of alloy material and flange, which is applied in the field of alloy material flange and its preparation, can solve problems such as cracking, low strength, leakage, etc., and achieve the effects of improving air tightness, improving wear resistance, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material composition (weight percentage chemical composition) Si5%, Cu2.5%, C0.5%, Ni0.1%, Fe1.5%, V0.1%, B0.3%, La0.01%, Ce0.01% , Nb0.02%, Os0.03%, modified epoxy soybean oil lubricant 0.01%, and the balance is aluminum.

[0034] Modified epoxy soybean oil is prepared by the following method:

[0035] Add 100g of dehydrated epoxidized soybean oil into the reactor, under the protection of nitrogen, heat to 45°C, add 0.1g of complex coupling agent, stir and react for 1h, add 5g of di-n-butylphosphoramide, raise the temperature to 55°C, and continue the reaction for 1h Afterwards, cool to 30°C and discharge, filter, and grind to a size below 1000 mesh to obtain modified epoxy soybean oil.

[0036] Include the following steps:

[0037] S1. Weigh the simple substances of each raw material in proportion, add them to the induction furnace for heating, melting, refining and degassing, and use the supersonic gas atomization method to circulate the molten metal into the d...

Embodiment 2

[0041] Raw material composition (weight percent chemical composition): Si10%, Cu4.5%, C0.7%, Ni0.4%, Fe5%, V0.3%, B0.5%, La0.05%, Ce0.03%, Nb0.04%, Os0.05%, modified epoxy soybean oil lubricant 0.05%, and the balance is aluminum.

[0042] Modified epoxy soybean oil is prepared by the following method:

[0043] Add 100g of dehydrated epoxidized soybean oil into the reactor, heat to 55°C under nitrogen protection, add 0.5g of complex coupling agent, stir and react for 3 hours, add 10g of di-n-butylphosphoramide, raise the temperature to 70°C, and continue the reaction for 2h Afterwards, cool to 35°C and discharge, filter, and grind to a size below 1000 mesh to obtain modified epoxy soybean oil.

[0044] Include the following steps:

[0045] S1. Weigh the simple substances of each raw material in proportion, add them to the induction furnace for heating, melting, refining and degassing, and use the supersonic gas atomization method to circulate the molten metal into the device ...

Embodiment 3

[0049] Raw material composition (weight percent chemical composition): Si8%, Cu3.5%, C0.6%, Ni0.25%, Fe3%, V0.2%, B0.3%, La0.03%, Ce0.025%, Nb0.03%, Os0.04%, modified epoxy soybean oil lubricant 0.02%, and the balance is aluminum.

[0050] Modified epoxy soybean oil is prepared by the following method:

[0051] Add 100g of dehydrated epoxidized soybean oil into the reactor, heat to 50°C under the protection of nitrogen, add 0.3g of complex coupling agent, stir and react for 2 hours, add 7g of di-n-butylphosphoramide, raise the temperature to 62°C, and continue the reaction for 1.5 After one hour, cool to 32°C and discharge, filter, and grind to a size below 1000 mesh to obtain modified epoxy soybean oil.

[0052] Include the following steps:

[0053] S1. Weigh the simple substances of each raw material in proportion, add them to the induction furnace for heating, melting, refining and degassing, and use the supersonic gas atomization method to circulate the molten metal into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com