Sludge biomass high-temperature gasification treatment method and treatment system

A treatment method and biomass gas technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of insufficient combustion in the treatment process, treatment cost, complex process, air pollution, etc. To achieve the effect of significant deodorization, simple equipment structure and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

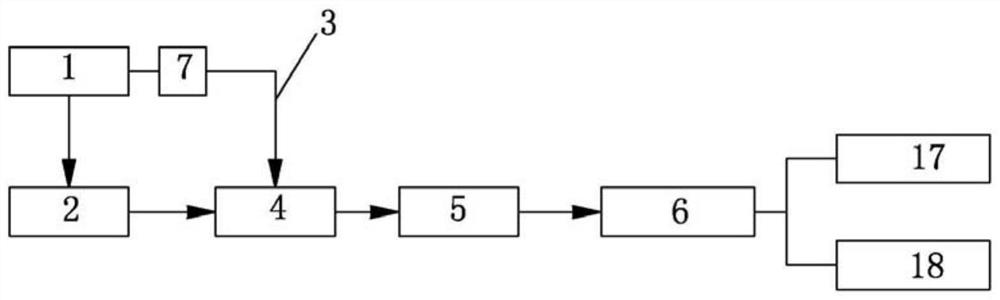

[0056] Such as figure 1 As shown, this embodiment provides a sludge biomass high-temperature gasification treatment system, including a sludge bin 1, a wood waste bin 2, a belt conveyor 3, a mixer 4, an aging device 5, and a biomass gasification furnace 6;

[0057] Sludge bin 1 is used to hold sludge, and is connected with described mixer 4 by sludge pump 7, belt conveyor 3 successively; Branches or waste wood strips or waste planks), and are connected with the mixer 4 by a belt conveyor 3;

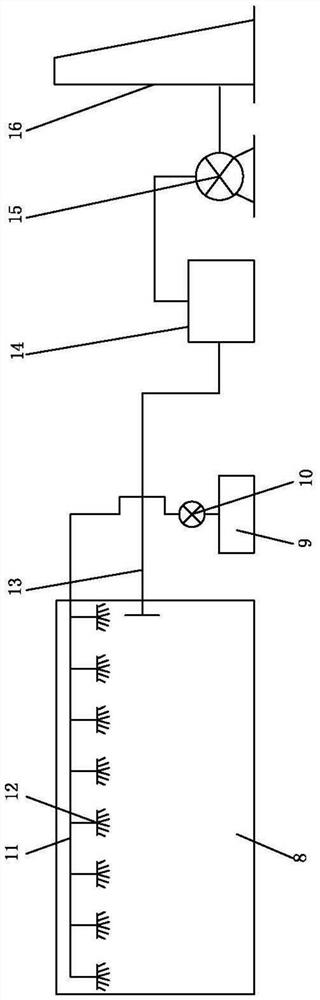

[0058] The aging device 5 is mainly used for natural dehydration and deodorization of the mixture of sludge and wood waste, such as figure 2 As shown, it mainly includes aging chamber 8, spray deodorization assembly and negative pressure deodorization assembly;

[0059] The spray deodorization component includes a liquid medicine pool 9, a water pump 10, a spray pipe 11 and an atomizing nozzle 12; , the output end of the water pump 10 supplies liquid medicine to the spray pipe 11; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com